Microstructural Characteristics and Mechanical Properties of

mechanical properties of high Cr white cast iron alloys are Figure 1: High chromium iron microstructures in the as-cast; (a) with austenitic matrix

Learn More

Introduction to High Chromium Cast Iron - EB Castworld

High chromium cast iron is the third generation of white cast iron developed from ordinary white cast iron and hard nickel cast iron .The chromium content of high chromium white cast iron is more than 11%, and the ratio of chromium to carbon is between 4~8.Under these conditions, M7C3 type carbides with high hardness almost completely replace

Learn More

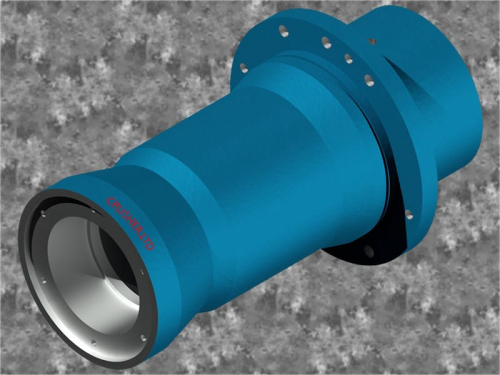

Ductile iron vs stainless steel corrosion - kxget.szaffer.pl

Jan 14, · The use of Victaulic couplings with ductile iron housings on stainless steel pipe is common practice when pipe material selection is based on compatibility with the fluid media and where the risk of external corrosion is low. Due to the design of the coupling housings and elastomer gasket, the housings will never contact the

Learn More

Microstructural effect and wear performance of high chromium

2021. 7. 15. · High chromium white cast irons are ferrous alloys with chromium contents of 11 to 30 wt% and 1.8 to 3.6 wt% carbon . Elements such as Molybdenum, Nickel Fig. 1a and Fig. 1b

Learn More

PDF Heat Treatment Effect on Microstructure, Hardness and ... - SpringerOpenPDF

The microstructures of HCCI specimens are examined by using optical microscopy and scanning electron microscopy. The hardness and impact fracture toughness of as-cast and heat treated specimens are measured. The wear tests are assessed by a Type M200 ring-on block wear tester.

Learn More

The Role of Manganese on Microstructure of High Chromium

To determine the effect of austenite stabilizer element on the microstructure and behaviour of as–cast high Cr white cast iron Fe-21Cr-3Ni-1.7Mo-2.4C,

Learn More

Microstructure and wear resistance of high chromium cast iron

2014. 5. 1. · The most commonly used high-chromium white cast iron (HCWCI) is the hypoeutectic white cast iron that contains 2-3.5 wt.% C and 10-30% Cr. This type of material relies on hard, brittle M7C3

Learn More

White Cast Iron - Types, Microstructure, and Applications - Materials Today

White Cast Iron Microstructure Development. For a general microstructure development in high carbon ferrous material and to understand the effect of equilibrium cooling and fast cooling, Follow Microstructure development in Iron. Cooling or directional solidification has a huge impact on microstructure of White cast iron. If fast cooling is only allowed on the surface than chill cast iron is developed which contains grey structure (graphite flakes) within the center region.

Learn More

Microstructure and properties of modified as‐cast hypereutectic high chromium cast iron

2022. 2. 17. · The present work studied the effects of different modification treatments on the microstructure and mechanical properties of hypereutectic high chromium cast iron containing about 35 wt% chromium and 4.0 wt% carbon. It was found that the primary carbides in the hypereutectic high chromium cast iron were all refined to different levels after different

Learn More

Variations in microstructure of high chromium cast irons and resultant

In this study, microstructures of a series of high chromium white cast irons (wt%Cr = 30, wt%C = 1, 2, 3, 4, 5 and 6, wt%Mn = 2, wt%Si = 0.5, balanced by iron) were cast and characterized, and corresponding resistances to wear, corrosion and corrosive wear were evaluated, respectively. It was demonstrated that the corrosion resistance of these high chromium alloys largely depended on the Cr concentrations in the matrix and the volume fraction of carbides, while the wear resistance was

Learn More

PDF Research Article Heat Treatment in High Chromium White Cast Iron Ti AlloyPDF

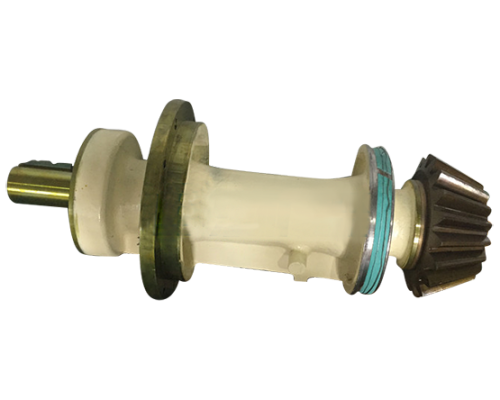

In the as-cast condition, the microstructure of high chromium molybdenum white iron consists essentially of dendrites of austenite in a matrix of eutectic mixture of austenite and (Fe, Cr)7C3carbides [ , ]. For many applications, castings are heat treated prior to service to increase the wear resistance as well as impact toughness.

Learn More

High chromium cast irons: destabilized-subcritical secondary

Xiao, Effect of heat treatment on microstructure and mechanical properties of a Ti-bearing hypereutectic high chromium white cast iron, Mater. Sci. Eng. A 487 (

Learn More

Carbides in High Chromium Cast Irons - ThaiJO

Keywords – High chromium cast iron, Eutectic carbide, Secondary carbide, Microstructure. 1. INTRODUCTION. High chromium irons can bridge the gap between the.

Learn More

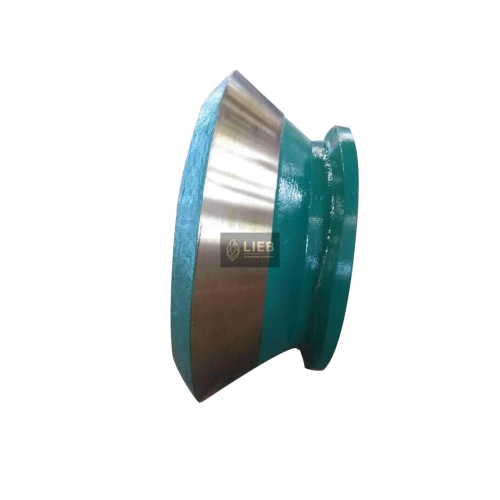

Microstructure of high chromium cast iron - ZHY Casting

Figure 1 shows the optical structure of high chromium cast iron obtained after corrosion with 4 vol.% nitric acid alcohol. Figure 1 (a) shows the as cast structure of high chromium cast iron. It can be seen from Figure 1 (a) that the white bulk eutectic carbide M7C3 is distributed on the austenitic matrix in a broken network.

Learn More

MICROSTRUCTURE AND PROPERTIES OF HIGH

The microstructure and mechanical properties of high chromium white cast iron with composition: 2,6÷3,4% C; 0,9÷1,1% Si; 0,8÷1,1% Mn; 1,0÷1,3% Mo;

Learn More

High-chromium and high-silicon cast irons

OSTI.GOV Journal Article: High-chromium and high-silicon cast irons

Learn More

PDF] Carbides in High Chromium Cast Irons - Semantic Scholar

High chromium cast irons are widely used as abrasion resistant materials. The mechanical properties and wear resistance of these irons depend on the type,

Learn More

Microstructure and mechanical properties of composite strengthened high

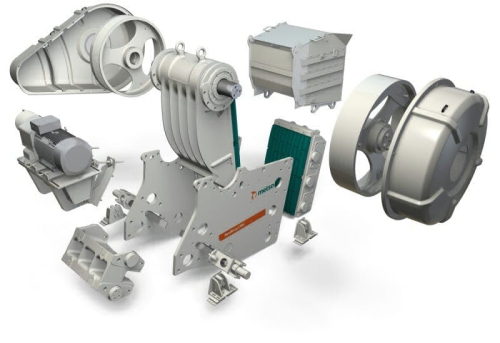

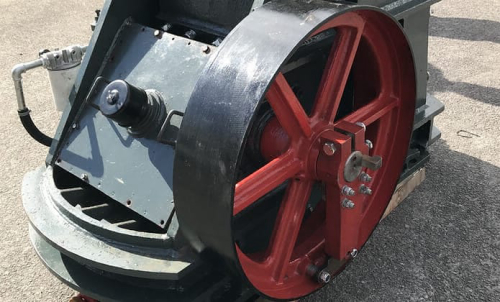

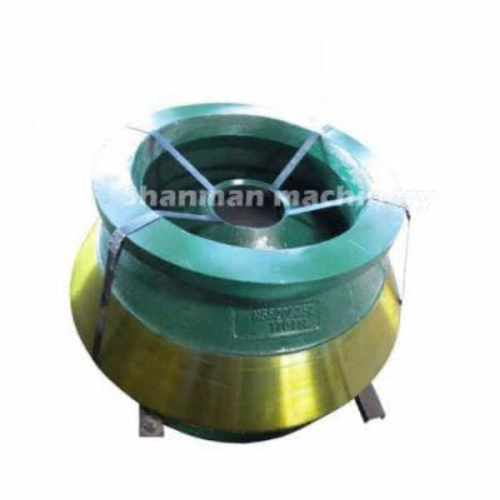

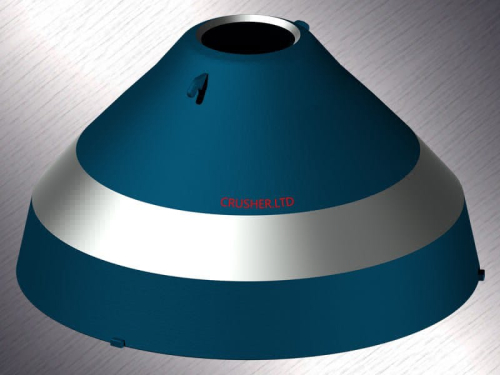

High-chromium cast iron (HCCI) is recognized as an excellent wear-resistant material in the world, and is widely used in mining, refractory materials, shot blasting machines, road construction machinery, etc [ 1 ].

Learn More

The Improvement of Wear and Impact Resistance of High

The microstructure of high chromium white cast iron after quenching is dominated by carbide and residual austenite. The types of carbides formed are M7C3 (Cr7C3

Learn More

Infuence of microstructure on machining performance high-chromium cast iron

The wear resistant chromium cast irons are known as materials with the extreme high abrasion resistance but also as difficult-to-cut ones. The abrasion resistance and mechanical properties of high chromium cast irons depend on a type, shape, and amount of carbides occurring in the microstructure, on matrix properties where they are lying, and on strength of a matrix - carbide junction.

Learn More

Microstructure and Sliding Wear Behavior of High

2022. 2. 10. · To improve the wear resistance of the low carbon steel (LCS), high chromium cast iron (HCCI) was embedded into LCS by the hot rolling technique. The macrostructure,

Learn More

Hot compression deformation and microstructure evolution of high

In this work, a canning compression process was developed to perform hot compression deformation of high chromium cast iron (HCCI) on a Gleeble 3800 thermomechanical simulator at temperature of 950-1150 °C and strain rate of 0.01 s -1. The hot deformation behavior and microstructure evolution of HCCI were investigated.

Learn More

Heat treatment effect on microstructure, hardness and ... - SpringerLink

The microstructures of HCCI specimens are examined by using optical microscopy and scanning electron microscopy. The hardness and impact fracture toughness of as-cast and heat treated specimens are measured. The wear tests are assessed by a Type M200 ring-on block wear tester.

Learn More

Effects of niobium macro-additions to high chromium white cast iron on

The microstructures consisted of M 7 C 3 and M 23 C 6 primary carbides as well as eutectic and secondary carbides. The M 23 C 6 was stated to have transformed from primary M 7 C 3 during the destabilisation treatment. Their BSE images showed that NbC to be located inside and on the edge of primary Cr-carbides.

Learn More

PDF Metallurgical Aspects of HIGH- CHROMIUM WHITE IRONS - foundry-planet.comPDF

Chromium is included in these alloys,atlevels from1.4 to4%to ensure that the irons solidify carbidic (i.e., to counteract the graphitizingeffectofnickel). Typical microstructure of class I type A nickel-chromium white cast iron.

Learn More

Microstructure of high-chromium cast iron after etching (scanning

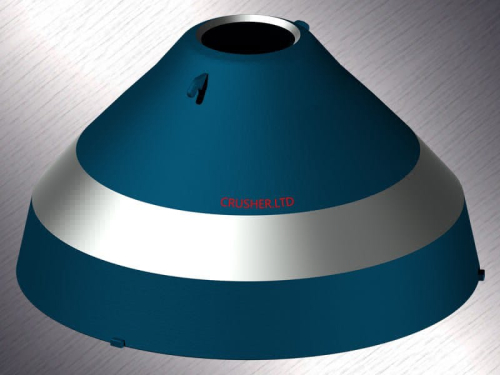

High-chromium cast iron is typically used for components operated in conditions characterized with intensive abrasive wear in power, mining, ceramic, cement, and aggregate supplying industries [1,

Learn More