Centrifugal Casting Machines | Large Centrifugal ... - Gibson

Large Centrifugal Casting Machine Loaded and ready to Leave Gibson Centri Tech Limited. This machine is from our Carosuel Range of Centrifugal Casting Machines. For more information on this machine or any of our other products email Tracey in Sales: [email protected]

Learn More

What is Centrifugal Casting - Centrifugal Casting Types, Advantages

Centrifugal casting with a large angle between the mold rotation axis and the horizontal and vertical lines is called inclined shaft centrifugal casting, but it is rarely used. Pros and Cons of Centrifugal Casting Centrifugal Casting Advantages - There is almost no metal consumption of gating system and riser system to improve the process yield.

Learn More

Large Centrifugal Casting Machine Manufacture and Large

China Large Centrifugal Casting Machine Manufacture, Visit Here to Find the Large Centrifugal Casting Machine That You are Searching for. Ms. Liu Li . What can I do for you?

Learn More

Large Volume Industrial Centrifugal Castings Engineering

Reduce Cost: Large volume industrial centrifugal castings engineering assistance - Allow our design engineers to help with process solutions and design considerations for ASME, ISO or other industry specifications. New technologies enable product and process innovations to be chosen and effectively utilized.

Learn More

Centrifugal Aluminum Casting & Aluminum Sand Castings | US Bronze

As a premier large centrifugal aluminum casting manufacturer, our aluminum parts are made using centrifugal force. It distributes and refines the molten material in the mold. High centrifugal force levels press the molten material against the mold wall, creating a dense tubular product. Products we produce include: Straight Bushings

Learn More

Leading quality bronze centrifugal casting with high grade

Centrifugal Casting Introduction. Process Video. Bajrang Bronze LLP is a global leader in the centrifugal casting and finished machining of high grade centrifugally cast non-ferrous products. Our patented near-net shape centrifugal casting machines and the process is unique and gives us the capability to take new challenges in our field.

Learn More

Centrifugal Casting - Applications - MetalTek

We can produce horizontal centrifugal castings with O.D. up to 60" (1,524 mm), length up to 432" (10,973 mm), and weight up to 135,000 lbs. (61,235 kg). With medium to high volumes, the

Learn More

The Centrifugal Casting Process - Sinotech Tutorial

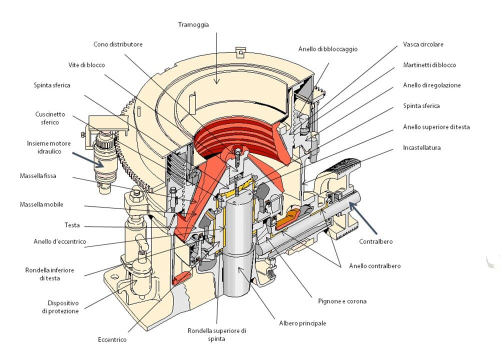

In centrifugal casting, a permanent mold is rotated about its axis at high speeds (300 to 3000 rpm) as the molten metal is poured. The molten metal is

Learn More

Lucas 750 Centrifugal Casting Machine | Contenti

The Lucas Giant Centrifugal Casting Machine will accommodate flasks up to 3 1⁄2" in diameter, 5 1⁄2" high. The long 22" arm provides the extra force needed

Learn More

Exploring the Centrifugal Casting Workspace - FLOW-3D

The vertical centrifugal casting process is ideal for large, symmetrical castings with a length similar or smaller than their diameter. Again, the spinning mold

Learn More

Bronze Castings - Centrifugal Bronze & High-Leaded Tin Bronze Machined

Components are manufactured using centrifugal and static casting techniques. We're also a leading large sand casting bronze manufacturer. Built-in automation and controls ensure improved precision and quality. As a premier large centrifugal bronze casting manufacturer, we specialize in making bronze parts using centrifugal force. It

Learn More

Comparison of properties of centrifugally cast and wrought stainless

The U.S. Department of Energy's Office of Scientific and Technical Information

Learn More

Large Centrifugal Casting Machine Manufacture and Large Centrifugal

China Large Centrifugal Casting Machine Manufacture, Visit Here to Find the Large Centrifugal Casting Machine That You are Searching for. Ms. Liu Li . What can I do for you? +8618952627811. Contact Now; Chat Now Jiangsu Taigoo New Material Co. Ltd. [email protected]

Learn More

Centrifugal Casting Machines | Centrifugal Casting machines - Gibson

Centrifugal casting is a long established process dating back to the original UK patent by A.G.Eckhardt in 1809. Gibson Centri Tech is one of only a few companies world wide whom specialise in centrifugal casting machine manufacturing. We understand the extreme environmental conditions to which a centrifugal casting machine is placed, and build

Learn More

Centrifugal Casting Services Company

Centrifugal casting in which the rotation axis of the mold has a large angle with the horizontal and vertical lines is called inclined axis centrifugal casting, but it is rarely used. Centrifugal forces help spread the molten material evenly. The metal cools as the mold continues to spin. Manufacturers may choose to maintain a constant high

Learn More

Large Centrifugal Castings

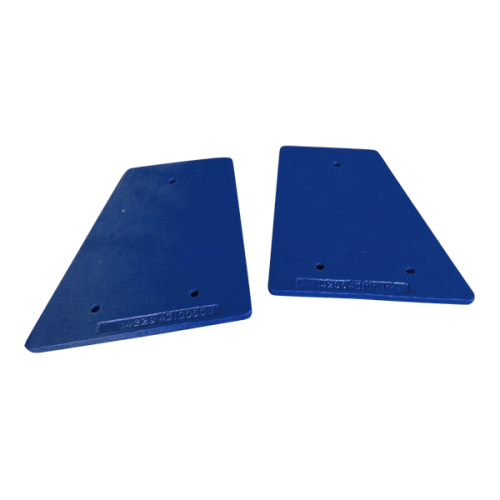

Large centrifugal castings creates finished products by pouring molten metal into a spinning cylindrical mold. The mold is reusable and consists of two or

Learn More

Centrifugal Casting | Technology | Materials & Steel Pipes

Centrifugal Casting The centrifugal casting method is the method to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation exerts pressure on the molten metal. In 1952, developed its first centrifugal casting technology for steel.

Learn More

Large Volume Centrifugal Castings Engineering | Custom Industrials Company

Reduce Cost: Large volume centrifugal castings engineering assistance - Allow our design engineers to help with process solutions and design considerations for ASME, ISO or other industry specifications. New technologies enable product and process innovations to be chosen and effectively utilized.

Learn More

Centrifigul Casting & Rotocasting | The Federal Group USA

Centrifugal casting or as it’s also known, rotocasting, is the process of creating cylindrical parts using gravity or pressure to fill a rotating mold. Machines used to rotocast are horizontal if long cylinders are being cast or vertical if rings are being cast.

Learn More

What is centrifugal casting - Wilsonpipeline

03/04/2022 · Centrifugal casting with a large angle between the mold rotation axis and the horizontal and vertical lines is called inclined shaft centrifugal casting, but it is rarely used. Advantage: Most centrifugal castings are tubular, sleeve and ring parts. The resistance encountered during liquid metal filling is small, and the centrifugal

Learn More

Centrifugal casting | Rice Foundries

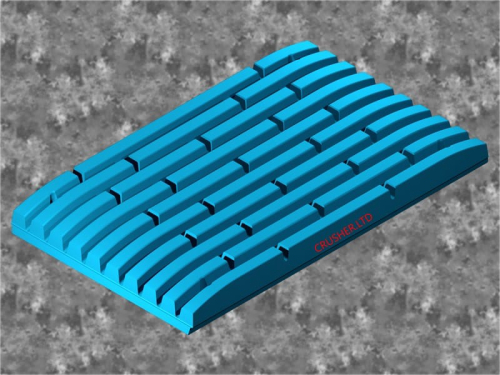

CHARACTERISTICS OF CENTRIFUGAL CASTINGS: 1) The piece is practically free from defects, with a tight closed grain and homogeneous finish. 2) No metallic impurities or residues on the piece. 3) Fewer loss of metal when pouring, compared to conventional sand molding. 4) Better mechanical properties. 5) High productivity, meaning a lot more pieces

Learn More

Design of control system for large centrifugal casting machine

Large centrifugal casting machines are mostly used to produce rolls. In centrifugal casting, the rotational speed of the mold (also called the tube mold) is very important, especially in the roll production, which requires secondary casting (adding core), and particularly requires strict control of the speed, time and temperature.

Learn More

Centrifugal Casting - Applications - MetalTek International

Centrifugal casting provides high material soundness and is the metal casting process of choice for jet engine compressor cases, petrochemical furnace tubes

Learn More

Bronze Centrifugal Castings ǀ Johnson Centrifugal | Johnson Centrifugal

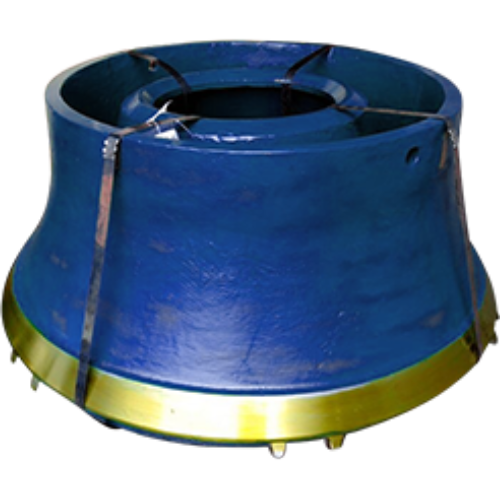

Bronze centrifugal castings and nickel silver castings produce bronze gear blanks, steam turbine repair parts, worm gears, crusher equipment parts, bronze bushings, mining equipment parts, brass bushings, and trunnion, pintle and brass bushings. Centrifugal technology is uniquely qualified to efficiently produce these large components

Learn More

Leading quality bronze centrifugal casting with high grade application

Centrifugal Casting Introduction. Process Video. Bajrang Bronze LLP is a global leader in the centrifugal casting and finished machining of high grade centrifugally cast non-ferrous products. Our patented near-net shape centrifugal casting machines and the process is unique and gives us the capability to take new challenges in our field.

Learn More

Centrifugal Casting | Technology | Materials & Steel Pipes

The centrifugal casting method is the method to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation exerts pressure on

Learn More