HP400 DUST SEAL | useful relationship used in plant design for gyratory

hp300 gear motor ka67dv132s4-5.5kw-135 1/min rock rock crusher copper bushing supply dc geared motor specifications. AGGREGATE SOURCES CAN BE GROUPED INTO THREE MAIN AREAS: Our equipment covers the entire unit operation range for aggregate plants. Westpro possesses the industry expertise to combine these products in a modular plant

Learn More

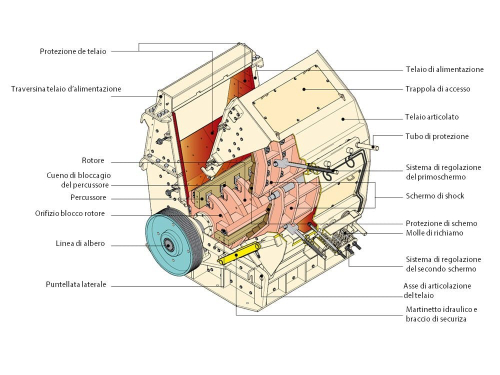

Use Range and Attentions of Gyratory Crusher - Luoyang Dahua

3/5 · author:dahua time: -03-05. The gyratory crusher is a large crusher which makes use of the gyratory movement of the crushing cone in the inner cone cavity to extrude, split and bend the material for various kinds of rocks and stones. Gyratory crusher is a typical coarse crushing equipment in a large mineral dressing plant. Both gyratory

Learn More

chapter 4 process plant design

The product size used was P8070 μm as determined in the laboratory flotation testwork by batch milling. The valuable components of the ore are sulfide minerals

Learn More

Gyratory Crusher l Introduce, Working Principle - JXSC

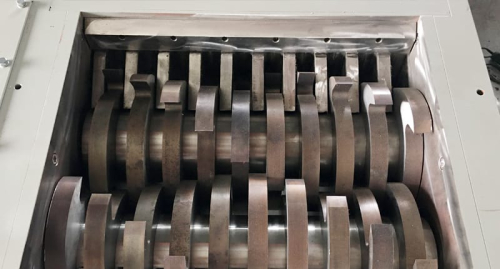

1. Double-chamber gyratory crusher is a crusher machine that continues working with a double-chamber. The crusher equipment changes the discontinuous working mode of single chamber

Learn More

where and spare crusher parts | useful relationship used in plant

Common Level Design; ELRUS USA. Colorado Springs. CO; 2442 Jaw Crusher; 3042 Jaw Crusher; 3054 Jaw Crusher; 2036 Feeder Screen Jaw Plant; CJ612 4448 Jaw Crusher; Screen Jaw Combo; Cone Crushers. CH660 Hydrocone; CH430 Self-contained cone; Self-Contained Compact Spread; Impact Crushers. Horizontal Impact Crusher. Vertical Shaft Impactor

Learn More

C63 CNTRL DEVICE C63-C125 | useful relationship used in plant design

Our equipment covers the entire unit operation range for aggregate plants. Westpro possesses the industry expertise to combine these products in a modular plant, providing its customers a complete process solution. 125 S802S-C125 125 S804S-C125 Tripping characteristic C IEC 690 VAC 50 kA Resistive loads • C Curve • Designed for use with

Learn More

Crushing Chamber Application Guide C5-1086:01ENG

It is based on our EF-mantle profile design and you can use it the jaw crusher needs to have a good feed level and a homogeneous feed.

Learn More

cone crusher performance - Chalmers Publication Library

Cone crushers are used by both the aggregate producing and the mining industry. A layout of a size reduction plant for comminution of a nickel rich ore

Learn More

Crushers and Their Types - IspatGuru

Jaw crusher is used as primary crusher. It uses compressive force for breaking the material. This mechanical pressure is achieved by the two

Learn More

jaw crusher toggle plate work | useful relationship used in plant

The toggle plate of the jaw crusher was supposed to break when uncrushable material passed through the crusher. The toggle plate did not break and did not act as a safety

Learn More

How do a gyratory crusher work?

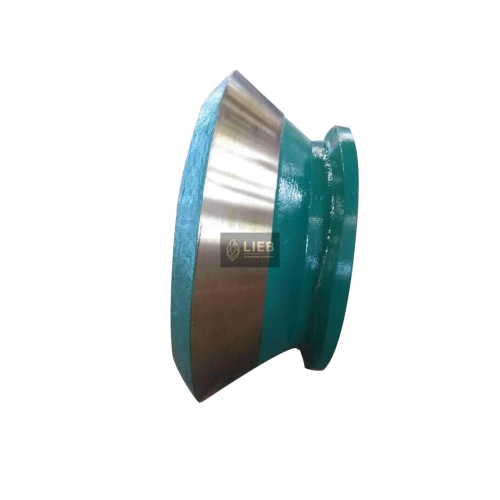

The movement is generated by an eccentric arrangement. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners (fixed) mounted on the main frame of the crusher. The gap is opened and closed by an eccentric on the bottom of the spindle that causes

Learn More

Crushing, screening, feeding and plant solutions

An often overlooked, but very important, characteristic of the single toggle jaw crusher is its kinematic design. 's chamber design enables the TST

Learn More

Non-traditional manufacturer pushes the crusher envelope

While the base technology that underpins crushers has not these rotary cone feeders into our plants because they do such a good job of

Learn More

GP100S part wear parts TS300 UNBALAN SECTR ASSY MV4-10MM

Whether it's aggregates, mining, construction & demolition, recycling or road building our jaw, cone & impact crushers are ready for any job. I4C Impact Crusher 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor

Learn More

Gyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

1. Double-chamber gyratory crusher is a crusher machine that continues working with a double-chamber. The crusher equipment changes the discontinuous working mode of single chamber of jaw crusher. 2. The characterize is that producing more fine products under the condition of larger discharge port. Under the premise of ensuring fine products

Learn More

Gyratory Crusher Plant - MX Series - CE AFRICA / Crusher Equipment Africa

011 568 8324 [email protected]. MX-Series Gyratory Crusher is mainly used in a very large primary crushing. MX-Series Gyratory Crusher has a unique crushing cavity design to ensure the best production capacity. The processing capacity range of single machine is ranging from 1500t/h to 7500t/h.

Learn More

spare parts useful relationship used in plant design for gyratory

This cookie is used to count how many times a website has been visited by different visitors - this is done by assigning the visitor an ID, so the visitor does not get registered twice. 1 day: HTTP: _hjFirstSeen: Hotjar: This cookie is used to determine if the visitor has visited the website before, or if it is a new visitor on the website. 1

Learn More

Gyratory Crusher

why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Learn More

Gyratory Crusher Design - Crushing, Screening & Conveying

Rock crushability index is a useful relationship, analogous to the Bond work index, for determining crushing energy for various crusher feed and products. If it is known what size

Learn More

Gyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing. Major components can be divided to ease transport

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining

thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and maintenance costs. Gyratories and jaw type gyratory crushers as an integral part of semi-mobile and stationary processing plants are used for primary crushing of bulk

Learn More

My Plant Planner - Outotec

Primary and secondary crushers in a closed plant · Excavate and transfer the raw material into a plant. · Material is reduced in a jaw crusher. · Material is

Learn More

Crushers - QueensMineDesignWiki

Crushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher is the size

Learn More

crusher parts | useful relationship used in plant design for

G10SEC O-RING BS4518-19.50X3.00 useful relationship used in plant design for gyratory crusher is toggle plate GP500S HYDR PUMP P257C386KVZA22-32 toucan single light

Learn More

Z174 FEED TUBE | useful relationship used in plant design for gyratory

GH3-mediated Auxin Homeostasis Links Growth Regulation. by JE Park · 2007 · Cited by 438 — mail.google.com. 04 6MT Sedan - Z Tube, K&N Drop-In, 04 Z Suspension.

Learn More