Man Injured by Defective Toggle Plate on Jaw Crusher

Jaw crushers are used to crush different types of material, such as hard rocks, ore, building rubble, and glass. Jaw crushers have one fixed and

Learn More

Function Of Flywheel In Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

The main components of the jaw crusher. The pulley also plays the role of the flywheel. Flywheel often cast iron or cast steel manufacturing, adjusting roles on a role crusher The pulley plays the role of the flywheel. The important role that crusher equipment play - The main parts of jaw crusher-Shanghai jianye 1.The Frame of Jaw crusher

Learn More

How to Calculate and Solve for Capacity of Jaw Crusher | Mineral

Now, Click on Mineral Processing under Materials and Metallurgical. Now, Click on Capacity of Jaw Crusher under Mineral Processing. The screenshot below displays the page or activity to enter your values, to get the answer for the capacity of jaw crusher according to the respective parameter which is the Gape Size (G), Width of Crusher (W) and Closed Single Setting of Jaw Crushers (CSS).

Learn More

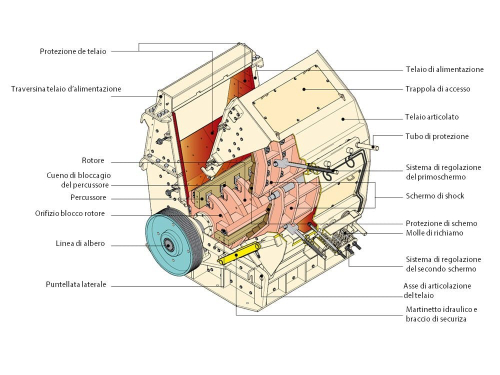

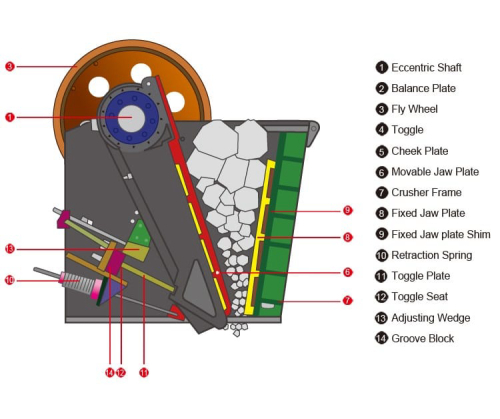

Jaw Crusher Main Components Function

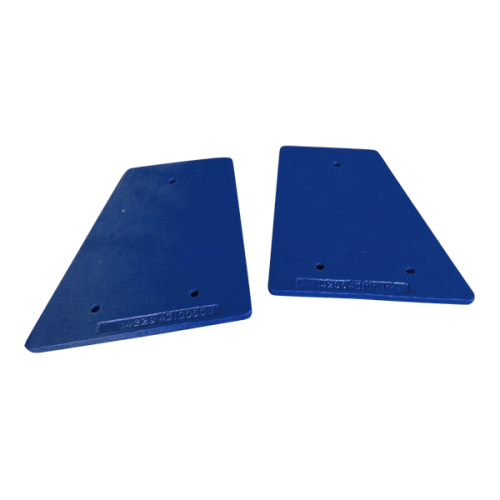

Today will be introduced six maine components function of jaw crusher. One,the jaw and the side guards: fixed jaw and movable jaw by the jaw and jaw bed composed jaw is working part fixed jaw and wedge bolts bed. Fixed jaw jaw bed frame is a front wall, moving jaw jaw hanging in the week on the bed, to have sufficient strength and rigidity to

Learn More

Function And Installation of Main Wear-resistant Parts In Jaw Crusher

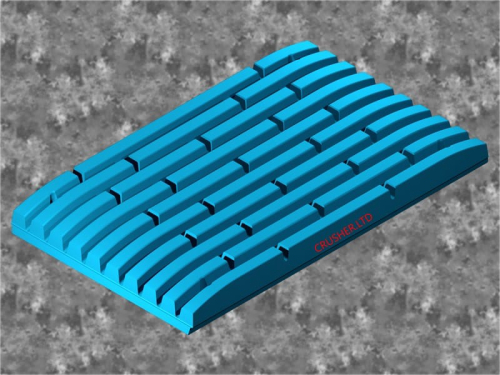

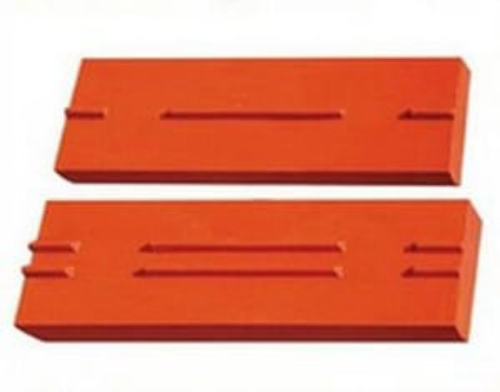

2021. 2. 23. · Jaw plates installation: jaw plates are the wear parts that need to be changed regularly, because the crushing cavity is formed of fixed jaw plate and movable jaw plate. By using a bolt or wedge, we can fix the tooth plate on the front wall of the frame and the movable jaw. The contact surface of the jaw plate and movable jaw must be straight.

Learn More

Jaw Crusher BB 200 - RETSCH - rapid and gentle crushing

Download. The Jaw Crusher BB 200 is a floor model designed for a throughput of up to 300 kg/h, suitable for many typical crushing tasks. It accepts feed sizes up to 90 mm. The gap width can be set stepless from 0-30 mm. Depending on the sample material, particle sizes down to 2 mm can be obtained, resulting in a crushing ratio of 45.

Learn More

What is a Jaw Crusher | Advantages, Types, Parts and

The series of jaw crushers produced by Rayco are widely used in mining and aggregate crushing industries. They are specially developed for crushing the

Learn More

Function And Application Of Jaw Crusher

US20130043335A1 Pitman of a jaw crusher jaw crusher. Application number US13212,342 Other versions US8757530B2 en Inventor Risto Sutti Jari Jonkka The function of the jaw crusher is based on the force pressing stone, the jaw moving in respect of an eccentric shaft moves back and forth regarding the fixed jaw.

Learn More

Jaw Crusher BB 500 XL - RETSCH

The Jaw Crusher BB 500 is specifically designed for accepting large feed sizes up to 110 mm. The gap width can be set stepless from 0-11 mm. Depending on the sample material, particle sizes down to 0.5 mm can be obtained in one working run, resulting in an excellent crushing ratio of 220. A throughput of up to 500 kg/h is possible with the BB 500.

Learn More

jaw crusher function | high efficiency jaw crusher copper parts with

Jaw Crushers. Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn More

Crusher - Wikipedia

Blake crusher-the swing jaw is fixed at the lower position · Dodge crusher-the swing jaw is fixed at the upper position · Universal crusher-the

Learn More

Jaw crusher: types, principle and applications - ResearchGate

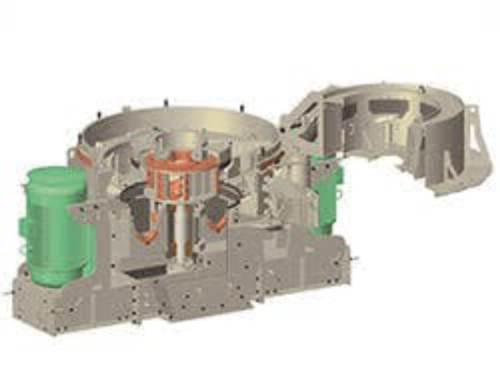

A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman

Learn More

Jaw Crusher - ScienceDirect

2016. 1. 1. · Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are manufactured by Locomo, ( ) and others. The crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors. Table 4.1.

Learn More

Jaw Crusher Explained - saVRee

How Jaw Crushers Work A jaw crusher uses compressive force for breaking ore pieces. Compressive force is applied by two jaws (dies), one of the crusher jaws

Learn More

Jaw Crusher Components & Parts - Mineral Processing & Metallurgy

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how they all go together.

Learn More

Jaw crusher uses and functions-SBM Industrial Technology Group

2019. 9. 12. · The jaw crusher is very powerful. It needs to carry out all-round inspection and replace worn parts during overhaul. The general overhaul period is 1-2 years. In combination

Learn More

1. Introduction Jaw crushers are widely used crushing

DYNAMIC BEHAVIOUR OF A VIBRATING JAW CRUSHER FOR DISINTEGRATION OF HARD MATERIALS of the function ϕ is gradually defined and, recalling (14), the.

Learn More

How Does a Jaw Crusher Work - Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn More

Function Of Jaw Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Introduces the Perfect Function of Jaw Crusher | Political Jaw crusher is suitable for crushing hard material (compression strength less than 250Mpa). For example: coarse and fine crushing operation by hammer crusher Jaw crushers,Jaw breaker, Primary,Mobile,Stone jaw crusher

Learn More

Impact Crusher Function | Crusher Mills, Cone Crusher, Jaw Crushers

PE-150×250 Importir Jaw Crusher Bandung; Jaw Cresher Stone Crusher Plant Ppt; Circular Vertical Vibrating Screen; PE-150×250 Jual Sillica Sand Powder Machine; function of crusher plant crusher machine for golden machine has made itself in the industryleaore position . as. Crushing Function of Impact Crusher for Materials.

Learn More

jaw crusher function | crusher spare copper-alloy casting importer sri

The function of the jaw crusher is based on the force pressing stone, the jaw moving in respect of an eccentric shaft moves back and forth regarding the Jaw Crusher VS Impact Crusher (A Comparison from 7 Points) Rock crushing equipment is widely used and plays a key role in the mining and construction industries. For the economical and

Learn More

What is the use of a jaw crusher? - Quora

A jaw crusher is a machine used for breaking up rocks. The Jaw crusher is used to reduce the size of rocks, and it is also used to remove materials from the

Learn More

In- depth – Components of a Jaw Crusher - Propel Industries

The jaw crusher is one of the most admired and most sought after equipment from the house of Propel Industries. For the benefit of newcomers

Learn More

Improving Productivity of Jaw Crusher through OTIF Delivery

Crushers are machines used to break or compress using the metallic plates during mining of materials. The chronic problem of High Maintenance cost and

Learn More

How to Calculate and Solve for Capacity of Jaw Crusher | Mineral Processing

2021. 11. 21. · Now, Click on Mineral Processing under Materials and Metallurgical. Now, Click on Capacity of Jaw Crusher under Mineral Processing. The screenshot below displays the page or activity to enter your values, to get the answer for the capacity of jaw crusher according to the respective parameter which is the Gape Size (G), Width of Crusher (W) and Closed Single

Learn More

Jaw Crusher For Sale | Jaw Crusher | Jaw Crusher Manufacturer

Jaw crusher for sale. Production Capacity: 1-1200 t/h. Feeding Size: 125-1200 mm. Application: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc. . The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa. Widely

Learn More