Types Of Primary Crushers Mineral Processing - HN droled mine

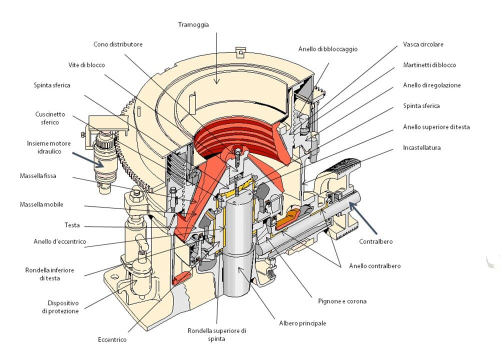

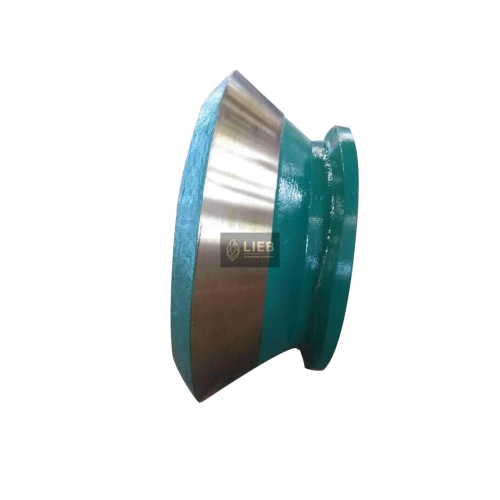

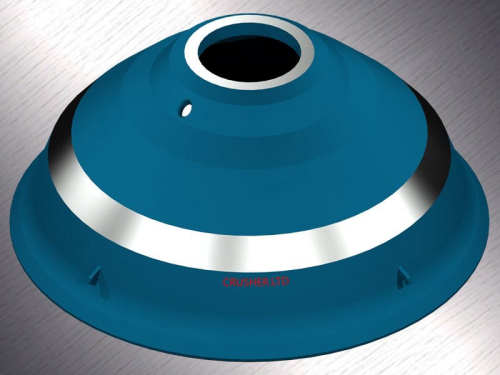

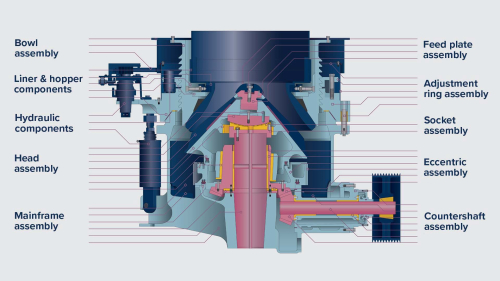

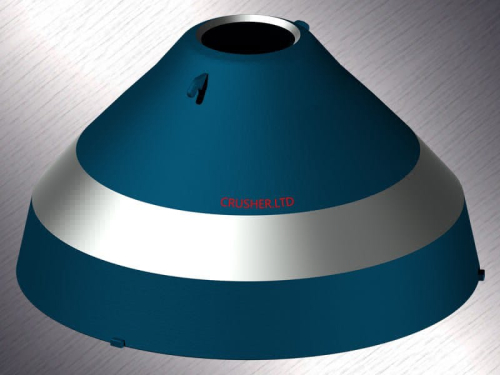

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter. Gyratory crushers play an important role in commi-. nution as primary According to the Mineral Processing Technology Roadmap. developed by the U.S.

Learn More

Primary and secondary crushers - Welding Alloys

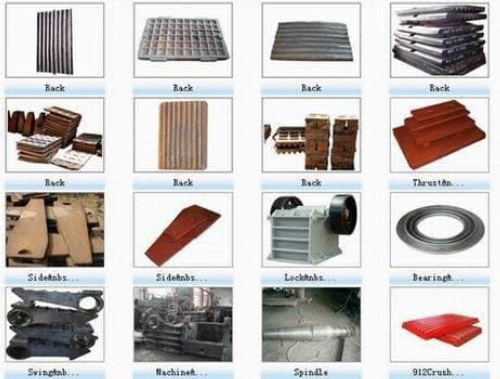

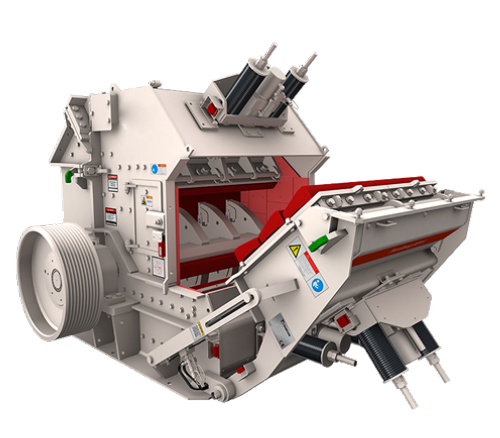

Where the material is not reduced sufficiently in the primary crusher, it is then crushed by a secondary crusher to achieve the correct size of the material. We have extensive experience in protecting all types of processing equipment, including gyratory crushers, jaw crushers, hammer crushers, and other impact crushers.

Learn More

types of primary crushers China Manufacture, Exporter, Supplier

types of primary crushers Our mission will be to become an innovative supplier of high-tech digital and communication devices by furnishing benefit added structure, world-class manufacturing, and service capabilities for types of primary crushers Africa and Eastern Europe. we are able to offer high-quality goods with all the pretty competitive

Learn More

Crushers - an overview | ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

Learn More

Types Of Primary Crushers-HN Mining Machinery Manufacturer

Types of primary crushers. Jaw crusher – Jaw crushers are used for extremely hard and abrasive materials, with reduction ratios typically as low as 6:1. However, jaw crushers are very durable, have low maintenance requirements, and are effective with almost any type of friable material. They represent a medium investment cost and, generally

Learn More

types of primary crushers prices

Large shovels scoop the oil sand into trucks which then move it to crushers where the large clumps of earth are processed. Once the oil sand is crushed, hot water is added so it can be pumped to the extraction plant. generally the process is broken down into two broad types of upgrading, namely primary and secondary upgrading. Primary

Learn More

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB

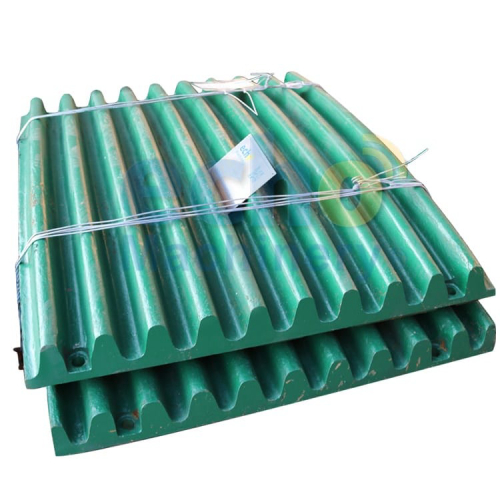

The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers. JAW CRUSHER. The jaw crusher squeezes

Learn More

Types Of Crusher - Working Principles of Crushers - Fabo

For example, in the mining industry, it is generally necessary to use a primary crusher and a secondary crusher first, and then a third or fourth type

Learn More

Different types of crushing equipments - Constro Facilitator

May 06, · Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher.

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Primary Crushing · The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding

Learn More

Different types of crushers for distinctive needs - Outotec

Dec 17, · Crushing 101 – Different types of crushers for distinctive needs Primary crushing is for the robust. The very first crushers invented were jaw crushers, which are built to reduce

Learn More

Three Types Of Primary Crushers - Facty Mining Machinery

The primary coal crushers may be of different types such as 1 coal jaw 2 coal hammer and 3 ring granulator. Secondary coal crusher Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is acceptable to the secondary crusher.

Learn More

Primary Jaw Crusher | Stone Crusher | FUREIN Machinery

Primary Jaw Crusher. Feed size: 125~1020mm. Capacity: different models with different output, as a professional jaw crusher manufacturer, we supply you with primary jaw crusher capacity at 1-800t/h. Application: Primary jaw crusher is mainly used for crushing medium-size stone and large materials, widely used in mining, smelting, building

Learn More

Types Of Primary Crushers Mineral Processing - HN droled mine treatment

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter. Gyratory crushers play an important role in commi-. nution as primary According to the Mineral Processing Technology Roadmap. developed by the U.S.

Learn More

Types of Crushers: What You Need to Know

Brief History of Crushers · Basic Ways to Reduce Material Size · Primary Crushing Equipment · Secondary Crushing Equipment · Tertiary Crushing Equipment and Beyond.

Learn More

Types Of Primary Crushers Mineral Processing-HN Mining

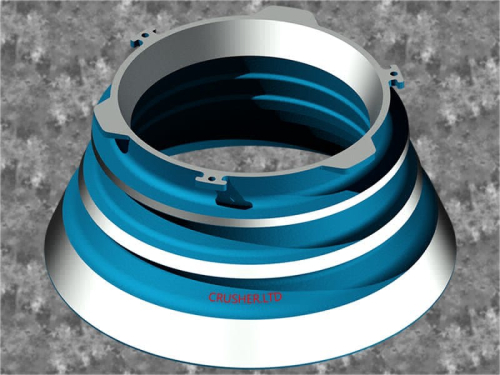

Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 1-1000tph. There are two types of feeding opening design, rectangular and square shape. The primary jaw crusher is usually designed with a square opening, while the secondary jaw crusher is designed with a rectangular opening.

Learn More

Different Types Of Crushers Machine Of Primary,secondary And

Jaw and Gyratory crushers are two most important types of primary crushers but SECONDARY AND TERTIARY CRUSHERS Cone Crusher. different kind of crushers

Learn More

An Overview on Different Types of Crushers

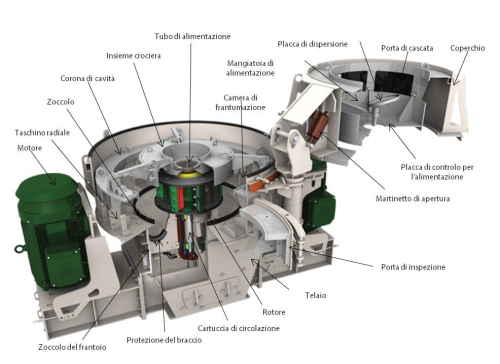

Jaw crusher: A crusher that breaks material by squeezing or compressing it between two jaw plates, one moveable and one stationary. Normally used as a primary crusher. Uses compression and some attrition to crush material. Reduction ratio is 6 to 1. Vertical shaft impactor: A crusher whose main mechanism rotates around a vertical axis.

Learn More

Primary Crusher Selection & Design - 911 Metallurgist

The mom and dad of primary crushers are jaw and gyratory crushers. In open-pit mines where high tonnage is required, the gyratory crushers are

Learn More

What is a Primary Crusher? - Fabo

Crushers are diversified relying to their process as premier crusher, secondary crusher and tertiary crusher. Primary crusher takse part in the first stage of crushing. Specifications of premier crushers used for crushing medium-hard and non-abrasive stones are: It performs best for non-hard stones O brings the material to the desired cubic ratio

Learn More

Stationary Crushing and Screening Equipment

jaw crushers are of the single-toggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton.

Learn More

Downstream Crushing Options for Secondary, Tertiary and… | McLanahan

Types of Tertiary and Quaternary Crushers For fine sizing, tertiary or even quaternary crushing stages may follow the primary and secondary stages. Cone Crushers are the most common types of tertiary and quaternary crushers, though Vertical Shaft Impactors and Roll Crushers can also be used depending on the application. Short-Head Cone Crushers

Learn More

Buyer's Guide: Crushers - Equipment & Contracting

As discussed in our article “Get to Know the Common Types of Mining Equipment” there are three classifications of crushers: primary, secondary, and tertiary

Learn More

5 Common Questions about Jaw Crushers Answered

What are the Different Types of Jaw Crushers? · Double Toggle—Blake Type or Overhead Pivot Movement · Single Toggle—Overhead Eccentric Movement.

Learn More

Compression mining crushers | Primary crushers

Compression mining crushers for your mining aggregate/cement needs field · Gyratory Crusher TS · Gyratory Crusher NT · Jaw Crusher TST · Cone Crusher Raptor®.

Learn More

Types of Crushers: What You Need to Know - Machinery Partner

At this point, the material receives its first reduction in size from its raw state. Primary crushing produces materials ranging from 1500mm to 350mm, on average. The two main types of

Learn More