clinker cement plant mill hzs120 ready mixed belt type concrete faqs

How does the Concrete mixing plant works. Concrete mixing plant is divided into four parts: gravel feed, powder (cement, fly ash, bulking agents, etc.) to feed, water and feed additives, transmission and storage stirred their workflow shown in Figure 1. , the mixer control system power, into the human - machine dialogue operation interface, system initialization process, including recipe

Learn More

Clinker Cooler, Cement Cooler, Grate Cooler | Clinker

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used to cool and transport the cement

Learn More

Clinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

As the supporting equipment of cement rotary kiln, clinker cooler (also called cement cooler) is a kind of heat exchange device that transfers heat from high-temperature clinker to low

Learn More

Upgrading a clinker cooler. IKN Klinker Inlet Distribution

Grinding of the final blend of clinker-gypsum additives has temperature limitations for the production of quality cement, and more and more cement producers

Learn More

The impact of cooling water types on the cement clinker

The plant includes industrial processes related to the production of white cement. It is using Nile water at different processes such as cooling clinker in the

Learn More

The polytrack® clinker cooler - innovative and sustainable

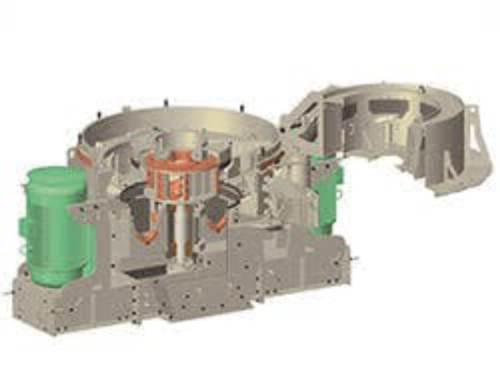

In the production of cement clinker, temperatures in the rotary kiln reach 1,300 to 1,400°C. In order to be able to grind the clinker into cement products, it has to be cooled to below 100°C. In more than 130 cement plants worldwide this task is performed by a cooling system developed by thyssenkrupp - the polytrack ®.

Learn More

Grate Cooler | Clinker Cooler, Cement Cooler | Cement Plant Equipment

Cooling clinker The clinker temperature is an important indicator of the grate cooler performance, which reflects the cooling efficiency of the grate cooler, and also creates conditions for the conveyer, storage, and cement grinding of clinker in subsequent processes.

Learn More

Clinker Production - Clinker Manufacturing | Cement Manufacturing Machines

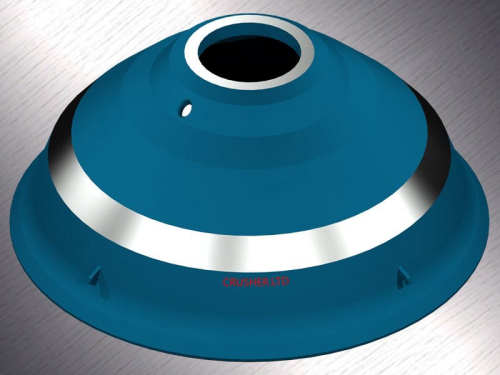

Clinker cooler is also called cement cooler, which set behind the cement kiln for clinker cooling. In cement plants, we usually adopt the rotary cooler and grate cooler for daily production. Inside the cooler, hot clinker will direct contact with the cooled air blown from the air blower to realize fast cooling. Clinker Cooler

Learn More

LT1100 SENSOR FPC F25.BM-F6-NPN | clinker cooler for cement plant

Our equipment covers the entire unit operation range for aggregate plants. Westpro possesses the industry expertise to combine these products in a modular plant, providing its customers a complete process solution. used rock crusher bottom shell bushing newest crusher clinker cooler crusher construction tools the eccentric bushing of ball

Learn More

White cement cooler - thyssenkrupp Industrial Solutions

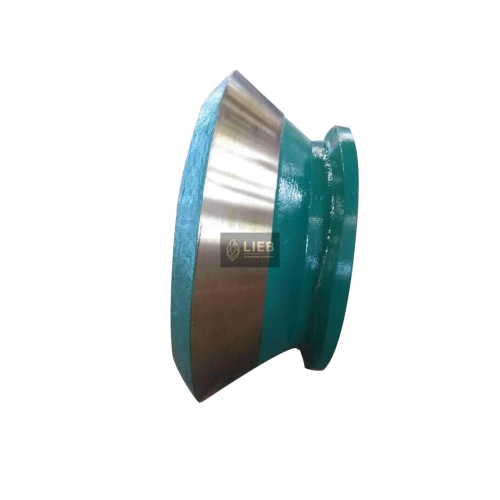

Especially for the white cement production process, thyssenkrupp Industrial Solutions developed the twin cooler, consisting of rotary cooler, roll crusher

Learn More

Clinker Production - Clinker Manufacturing | Cement

Clinker cooler is also called cement cooler, which set behind the cement kiln for clinker cooling. In cement plants, we usually adopt the rotary cooler and grate cooler for daily production. Inside the cooler, hot clinker will direct contact with the cooled air blown from the air blower to realize fast cooling. Clinker Cooler

Learn More

Continuous level measurement for cement clinker coolers

In cement production, the heart of the system is the rotary kiln, and the corresponding cooling system that follows. The efficient operation of these two

Learn More

Cement Production | Cement | Howden

Changshan South Cement, China benefitted from a cost-saving energy retrofit of its two clinker production lines with MC-2x39No30.5F raw mill circulation fans. Fan Retrofit at St Marys Cement Howden team retrofit an existing Induced Draft (ID) fan resulting in annual savings of $200,000.

Learn More

Capturing Clinker Cooler Emissions | World Cement

The clinker cooler is a critical component in the production of quality clinker in a cement plant. As the cement industry continues to optimise clinker to meet more stringent quality requirements and reduce CO 2 emissions from plants, proper and consistent cooling takes on greater importance. The cooler also has a significant impact on overall efficiency as the effective use of tertiary and

Learn More

Grate Cooler in Cement Plant

The grate cooler in a cement plant cools and transports the cement clinker from the rotary kiln, and provides heating air (secondary air) for the rotary kiln

Learn More

Polytrack Cooler - Clinker Cooling System In Cement Plant (Kiln System

Polytrack Clinker Cooling System In Cement Plant (Kiln System Part 11) in English Version.Polytrack Clinker Cooler, High availability and robustness for cont

Learn More

Clinker Cooler - AGICO Cement Plant

The clinker cooler is mainly used to cool and transport the cement clinker. At the same time, cement cooler also provide hot-air for rotary kiln and calciner,

Learn More

Cement clinker - Wikipedia

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres (0.12 in) to 25 millimetres (0.98 in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

Learn More

Clinker Grate Cooler for Cement Plant - Rotary Kiln

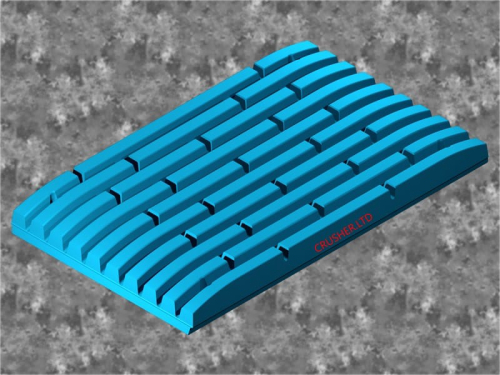

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the

Learn More

Evaluating the thermodynamic efficiency of the cement grate clinker

Fig. 1 shows the experimental data acquisition position with a simple two-dimensional cooler for a 3000 t/d cement plant. The operating functions of the grate clinker cooler include: on the inclined fixed grid plate, the clinker in the rotary kiln is dropped and the moving grate plate moved the clinker forward with the aid of the moving bar.

Learn More

Clinker Cooler - 911 Metallurgist

It was immediately successful in the cement industry. The capture of secondary combustion air above the cooling clinker was a big forward

Learn More

CemProTec, Isernhagen, Region Hanover, Cooler Technology for Cement Plants

What is a clinker cooler? The rotary kiln of a cement plant charged with raw meal.The so-called cement clinker leaves the rotary kiln at a temperature of around 1450°C and falls into the clinker cooler. This cools the clinker with air to usually 100°C. About half of the air is fed to the kiln system to supply oxygenas hot combustion air.

Learn More

Energetic and Exergetic Efficiencies of a Grate Cooler in an

clinkers coming out of rotary kilns. This work focuses on the thermal performance of the clinker cooling system in a cement production plant employing the

Learn More

Clinker Grate Cooler for Cement Plant

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the cement clinker. At the same time, it

Learn More

Clinker Cooler - Grate Cooler Latest Price, Manufacturers

Clinker Cooler · Dry Horizontal Flow Mild Steel Clinker Cooler ESP for Cement Plant, Automation Grade: Fully

Learn More

Grate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

Cooling clinker The clinker temperature is an important indicator of the grate cooler performance, which reflects the cooling efficiency of the grate cooler, and also creates conditions for the

Learn More