Optimal feed arrangement — SRP

You are here: Home Crushology The Knowledge Hub Crushing chambers Optimal feed arrangement Optimal feed arrangement Poor feed conditions can adversely affect productivity and liner life, so it is vital that you get it right. We have picked out two areas that are especially important to think about - choke feeding and spider arm placement.

Learn More

Cone crushers - for demanding crushing needs - Outotec

MX™ Series cone crushers utilize a revolutionary technology that combines a rotating bowl with piston into one crusher. Known for lower operating costs, high uptime and consistent high-quality output, MX™ Series cone crushers are ideal for secondary, tertiary and quaternary stages in hard and soft rock applications.

Learn More

Cone crusher basics in 4 minutes — SRP

This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information

Learn More

Cone Crusher Faq

A jaw crusher is able to crush a material in the range of 125 mm to 1500 mm. A cone crusher is used for secondary crushing. The input to the cone

Learn More

Cone Crusher | Working Principle | Animation

8/15 · Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. Basics of Pressure and Pressure Gauges June 10, 2022 Guide to Capping

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Jaw Crusher · Crushing occurs between two moving plates that are arranged to form an acute angle to apply a compressive force that results in tensile failure

Learn More

Basic principle of cone crusher - Consuol Mining Machinery

Basic principle of cone crusher Jul 14, This is the starting point for understanding how cone crushers work - and how they can improve the productivity of your mine or quarry. Inside your cone crusher. The basic principle is simple: the material to be crushed

Learn More

12 tips to maximize cone crusher productivity - Outotec

Cone crusher productivity can be easily increased by a minimum of 10 % by having better feed control. It can be achieved by using surge piles,

Learn More

Crusher - Wikipedia

Contents · 1 Background history · 2 Industrial use · 3 Types of crushers. 3.1 Jaw crusher; 3.2 Gyratory crusher; 3.3 Cone crusher. 3.3.1 Compound cone crusher; 3.3

Learn More

Cone Crusher - an overview | ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are

Learn More

Cone Crusher | Working Principle | Animation - Engineering Intro

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from

Learn More

basics of cone crusher

Portable Rock Crusher / Aggregate Crushing Plant For Sale 48FC Cone Crusher. Used 1999 Model 500-05CV Portable Impact Crushing Plant, s/n 11617, Plant Rated at 100-to-150 TPH, with 6,800 hours of use, احصل على السعر

Learn More

What is a Cone Crusher? - Definition from Trenchlesspedia

A cone crusher is mechanical device that reduces the size of rocks through a crushing process. It is one of several types of rock crushers

Learn More

Cone Crusher Total Power Trip

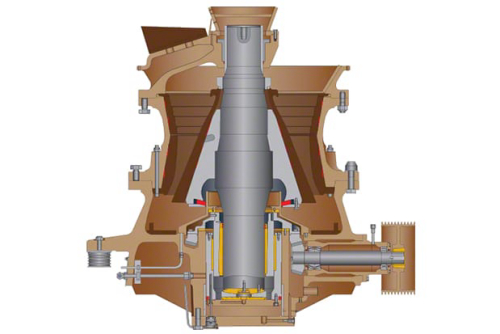

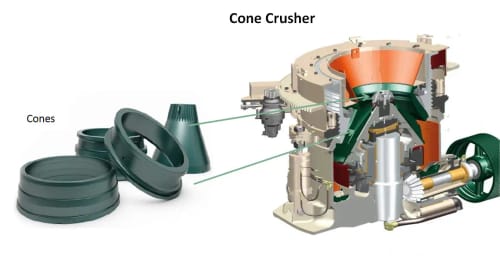

Inside your cone crusher. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber.

Learn More

Basics Of Cone Crusher Design

In mineral processing design and operations 2016. 5.1 introduction. gyratory crushers were invented by charles brown in 1877 and developed by gates around 1881 and were referred to as a gates crusher 1.the smaller form is described as a cone crusher. the larger crushers are normally known as primary crushers as they are designed to receive run

Learn More

How To Adjust Cone Crusher Gap

Cone crusher basics in 4 minutes — SRP. Inside your cone crusher. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion. That is, it doesn't remain completely centred - it swings slightly as it rotates, continually

Learn More

REAL-TIME OPTIMIZATION OF CONE CRUSHERS - CORE

Cone crushers are used in the mineral, mining, and aggregate industry for The basic principle of a cone crusher is depicted in Figure 9 and described

Learn More

Cone Crusher - Mineral Processing & Metallurgy

4/19 · The cone crusher is usually set to give a 3/8-in. or ½-in. product when discharging to ball mills. Table 9 gives particulars of the different sizes of crushers. The capacity figures are

Learn More

Aggregate Training Center, Aggregate Training Classes Michigan - AIS Equip

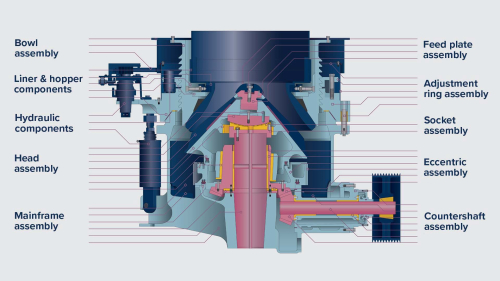

Aggregate Basics. WHEN: January 12th & 13th 8:30am-4:30PM. February 23rd & 24th 8:30AM-4:30PM **Lunch and dinner are included. Hotel information on the left. Courses: Crushing 101: Learn the basic parts and operations of aggregate crushers. (Gyratory, Cone, Jaw, VSI (vertical shaft impactors), HSI (horizontal shaft impactors), and Roll Crushers.)

Learn More

A Detailed Overview of Cone Crushers and What You Need to Know

6/3 · Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete,

Learn More

4 fine cone crusher

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a

Learn More

Crushers - All crusher types for your reduction needs - Outotec

For cone crushers there are few rules to be followed of optimum cubical shape. These 'Ten Golden Rules' are: Full crushing chamber. This means that cone head must be covered by rock. Stable and continuous feed. Material below setting in the feed 10-30% (but no filler and fines 0-4 mm normally). Maximum feed size.

Learn More

cone crushers basics

basics of cone crusher design Manganese Ore Mining Processing Process manganese ore beneficiation plant Mining And Crushing eeva 20121130 Manganese crusher . basic of cone crusher omindustries co in .

Learn More

Cone Crushers | McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a

Learn More

Cone Crushers Basics

Cone crusher basics in 4 minutes this is the starting point for understanding how cone crushers work - and how they can make your mine or quarry more productive. elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Learn More

Crushing and Screening Handbook - AusIMM

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric.

Learn More