Jaw Crusher Plate Material - MGS Casting

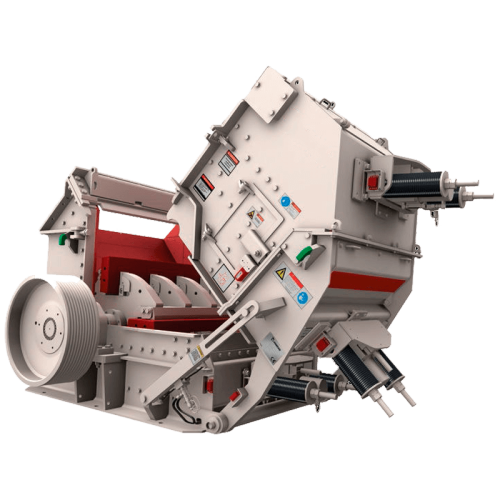

The crusher jaws are set at an acute angle such that one jaw is pivoted and the other jaw is fixed. The pivoted jaw swings around the pivot and makes the impact on the fixed jaw, crushing the fed lumps in the jaw crusher. Jaw crusher plates are the main jaw crusher parts, which need to change frequently.

Learn More

Used Heavy Stationary Jaw Crusher for sale. Polygonmach equipment

The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42" x 20' (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine. This plant inc Chilliwack, British Columbia, Canada. Click to Request Price.

Learn More

Jaw Crusher Liner, Swing and Stationary Jaw Plate

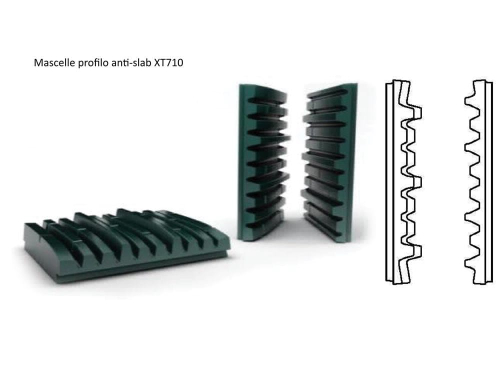

The jaw crusher liner is also called the tooth plate, which is an important part of the jaw crusher. A set of jaws is usually composed of movable jaws and fixed jaws. According to different models of jaw crushers, the jaws also have the same size and model. As the preferred equipment for coarse crushing, the aggregate industry has high

Learn More

Jaw Crusher Data Base – Jaws Mini Crushers

Welcome to our Jaw crusher data base, here you can scroll down through the list of jaw crushers that are popular in the crushing and recycling of building waste. Click on the crusher you are interested in to discover the crushers specification. Crusher manufacture Model; Angry

Learn More

Jaw crushers, Stationary Jaw crusher series — SRP

Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop. The wide range of jaw plates can be mixed and reversed to

Learn More

How Does a Jaw Crusher Work - Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary

Learn More

Type of crushers and their difference - JXSC Mining

10/12/ · Jaw crusher is used as primary crusher, it’s reduction ratio is usually 6:1. It uses compressive force to break the material, this mechanical pressure is achieved by the two jaws of the crusher. It is called a jaw crusher because it works the same was a human jaw does-food goes into your mouth and your bottom jaw pushes the food up against

Learn More

crusher jaws | crushers

Crusher jaws Incorporated in 1992, Chongqing Huade Machine Manufacturing Co.,Ltd have 3 factories with 505 workers with a production capability of 1200mtons per month. An individual piece casting of weight from 10 kg to 11000 kg,including high manganese,high Chromium,carbon steel and bronze steel crusher spar

Learn More

Stationary jaw crushers - rockprocessing

jaw crushers are reliable, high-performing crushers built to optimize primary crushing applications in mines and quarries. These tough crushers are

Learn More

Jaw Crushers for sale

OLESI 8 Orbital Jaw crusher rock grinding mill gold mining equipment silver ore. $8,400.00. or Best Offer. 46 watching. SPONSORED. I-Rock 2440 Track Jaw Crusher. Cat Diesel Power 500 Hours,

Learn More

Jaw Crusher Explained - saVRee

A jaw crusher uses compressive force for breaking ore pieces. Compressive force is applied by two jaws (dies), one of the crusher jaws is stationary (fixed jaw)

Learn More

Jaw Crusher | Product Information | KURIMOTO, LTD

Double-toggle crusher designed particularly to crush a large amount of robust raw stone. Offers outstanding durability. Commonly used as primary crushers for

Learn More

Heavy Duty Jaw Crusher Latest Price ... - IndiaMART

The laboratory Aggregate Jaw Crusher is designed for fast crushing of aggregates, ores, minerals, coal, coke, chemicals and other similar materials. Its compact

Learn More

Crusher Jaws Jaques Crushers

From primary jaw crushers to laboratory jaws, Jaques provide Posts Related to jacques 42 – 30 single toggle jaw crusher manual. jacques 3a hammer mill. Pe=250-400 Jaques

Learn More

Jaws Mini combo Crusher - Jaws Mini Crushers

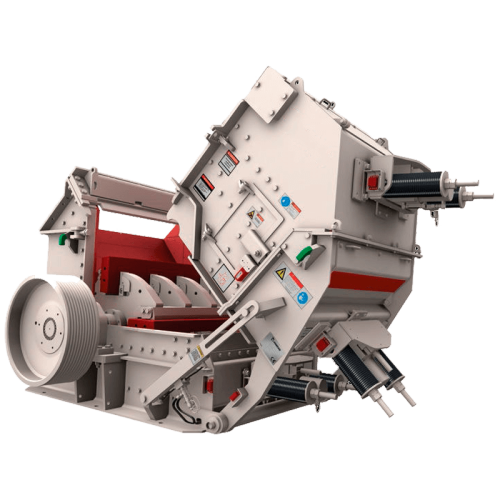

Jaws Mini combo Crusher, The Jaws Mini Crusher is designed to deal with a multitude of site waste, reducing all materials to skips, reusing them on site or even being sold on as a usable product! Never before has a machine been so versatile. The Jaws Mini Crusher is made up of 2 separate units:

Learn More

Jaws Mini Crushers - Hire and sales of mini crushers based in the UK

The crushing system is made of 18% manganese fusion jaws, while the casing is entirely made of high strength material. The output size is easily adjustable and the loading hopper as well as the supporting frame can be customized. Made in Italy, it is produced in two models: CR 400 and CR 600.

Learn More

Trio® CT Series Jaw Crushers - The Weir Group

The Trio® CT Series jaw crusher is a robust comminution machine with innovative features that make it the clear choice for primary crushing applications within

Learn More

Crusher Jaws Mobile Rock Crushers

Extremely portable, track mounted jaw crusher, , USED crushers of various brand plus NEW Beyer and Red Rhino mini crushers. Hartl Bucket Crusher HBC 650 - Jaws Crushers, Jaws Crushers has machines ranging our crusher is able to process natural rock as well as , This is a flexible and mobile product which is used for ,

Learn More

Crushers - All crusher types for your reduction needs - Outotec

Jaw crushers . Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to the next crushing stages. As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw.

Learn More

How To Make Crusher Jaws

A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman mechanism, , how a jaw crusher works and what it is used for, jaw crushers, thier operation and uses , Jaw Crushers, How Do They Work? Below Is A Animated Gif Showing How A Jaw Crusher Crushes,

Learn More

CR Mini Crusher - Jaws Mini Crushers

Mini electric jaw crusher CR series is ideal for the recycling of aggregates from small demolitions, excavations, natural stones, rock, tiles, scraps of marble, reinforced concrete. It can be easily moved thanks to its small dimensions. It is produced in two models and requires only a 380 V power supply.

Learn More

Hydraulic Jaw Crusher Market with Emerging Growth 2022 | Top Key

Global Hydraulic Jaw Crusher Market Large-scale Researchers 2022-2028 has covered a competitive market area and a thorough evaluation of industry pioneers. This research looks at the essential

Learn More

Jaw crushers by SIEBTECHNIK TEMA. Crushing & milling

Jaw crushers are used for coarse grinding brittle, medium-hard to hard materials up to a Mohs' hardness of approx. 8.5. Here reduction ratios of up to 1:100

Learn More

Used Jaw Crushers for Sale | Surplus Record

Used 11" Denver jaw crusher, on stand with 7.5 hp, 230/460 volt motor.

Learn More

Pioneer® Jaw Crushers - Astec

The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology.. Engineered to be the highest-capacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower requirements and class-leading stroke for higher capacity and you have a

Learn More

PE600X900 Jaw Crusher - China Jaw Crusher and Rock Crusher

Jaw Crusher is ideally suitable as primary and secondary crusher for material with compression strength less than 320Mpa. Jaw crusher is widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc,is a

Learn More