Fault and Troubleshooting Method of Jaw Crusher (4

12/3 · Fault phenomenon 2: Moving jaw fracture The reason: 1) There are serious defects such as intensive pores in the casting; 2) Unqualified brackets and brackets are used. When the crusher is in strong impact, the brackets are not self-breaking; 3) The moving

Learn More

Troubleshooting Impact Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

jaw crusher regular problems and solutions. q1:dissatisfied capacity probable reasons: . 2. too small discharging outlet setting,so jaw plates impact or strike.

Learn More

Eight common faults and solutions for jaw crusher

The reason for the above situation is: the pull rod and pull rod spring of jaw crusher are damaged. At the same time, if the elbow plate has

Learn More

Troubleshooting Manual For Cone Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

cedar rapids cone crusher troubleshooting – Crusher South Africa cedar rapids roll crusher manual. 1976 544 cedar rapids crusher service manual CEDARAPIDS COMMANDER, Used CEDARAPIDS COMMANDER, CEDARAPIDS Stk #: CR555; Closed

Learn More

Jaw Crusher common troubleshooting methods - Heavy Industry

Troubleshooting: 1) removal of nesting material inlets to ensure the smooth flow of materials 2) tighten the belt or replacement of the triangular 3) to re-install or replace the bushing tight set 4) transfer of the voltage is the workplace to meet the requirements of the host operating voltage 5) the replacement of bearings. 2.

Learn More

crusher trouble shooting

cause analysis and problems solving of jaw crusher | Dec 10, · 1 Replace or increase the crusher. 2 Change the motor wiring. 3 The discharge opening is adjusted to the nominal discharge opening specified in the manual and the crusher used for fine crushing is added. 4 Check the tooth gap size of the tooth plate.

Learn More

What Are Major Problems In Jaw Crusher?

Solutions to problems of the jaw crusher. Jaw Crusher Bearing Temperature Limit and Failure Solution Jaw crusher is the main ore or stone crushing plant in sand industry. Thus fever

Learn More

Jaw crusher routine maintenance and troubleshooting : grind

Jaw crusher daily repair: fixed and movable tooth plate repair (or U-turn); both sides of the liner replacement, thrust plate inspection or Press J to jump to the feed. Press question mark to learn the rest of the keyboard shortcuts Search within r/grind r/grind 1

Learn More

Jaw crushr operate manual: how to install, repair and examine it

After 3-4 minutes, when the oil pressure and oil flow indicator are normal, start the motor. After starting, if the jaw crusher makes an

Learn More

Repairing and Troubleshooting for Jaw Crusher (II) - Luoyang Dahua

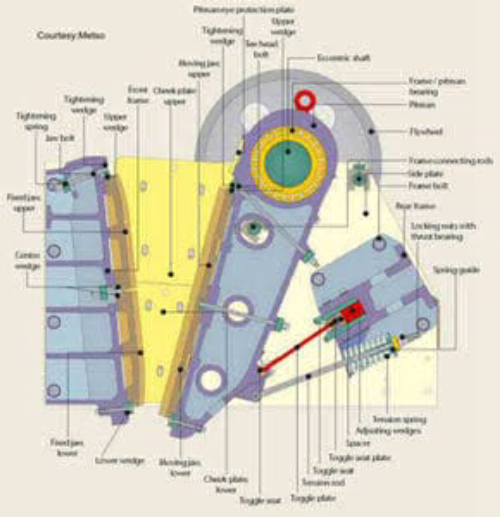

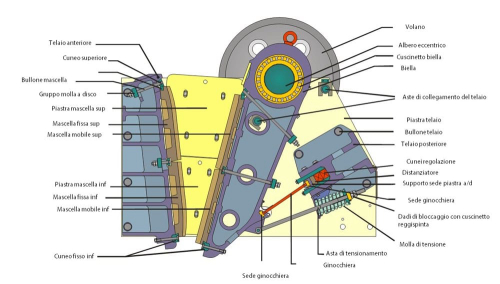

The large type of jaw crusher could be recovered to the operational performance by overhauling if necessary. The repair contents of jaw crusher are as follows: (1) Clean and inspect the eccentric shaft and bearings, usually the eccentric shaft and bearings should be cleaned once every 6-8 months and be replaced when the clearance of rolling

Learn More

troubleshooting jaw crushers | Mining & Quarry Plant

Common trouble and trouble shooting of Jaw crushers Malfunction: Crushing job stops Adjust seat off – 1) adjust the seat and replace the assembly replace the Stone Crushing

Learn More

Jaw Crusher with "Multi Jaws" for Fine Crushing - Mineral

12/25 · It cannot work out while the crusher is in operation. The adjustment does not require more than a few minutes. The settings range from 2.5″ inch material to 0.5″ in the stock size models. Description: The main Frame and all other principal parts; are of open-hearth cast steel, accurately machined and fitted.

Learn More

Troubleshooting Cone Crusher Problems

Related to problems faced in jaw crusher. vibrating SCREEN TROUBLESHOOTING. MVP-type cone crusher structure is significantly different from traditional cone 5565 jaw crusher problems - Grinding Mill China

Learn More

Maintenance and Repair of Jaw Crusher | JXSC Mine

The jaw rock crusher adopts Mobil Grease or 3 lithium grease, every work 400 hours to add the proper amount of oil; work 2000 hours to open the spindle assembly

Learn More

Regular crusher maintenance integral to reliability, performance and

Checking the air filter to ensure the crusher is vented properly and that unwanted contaminates are not entering the breather Checking the strainer basket on a cone crusher ensuring that there are no signs of excessive wear or damage to internal components Greasing bearings if required to ensure proper lubrication and cooling of those bearings.

Learn More

Common Crusher Problems | Crusher Mills, Cone Crusher, Jaw Crushers

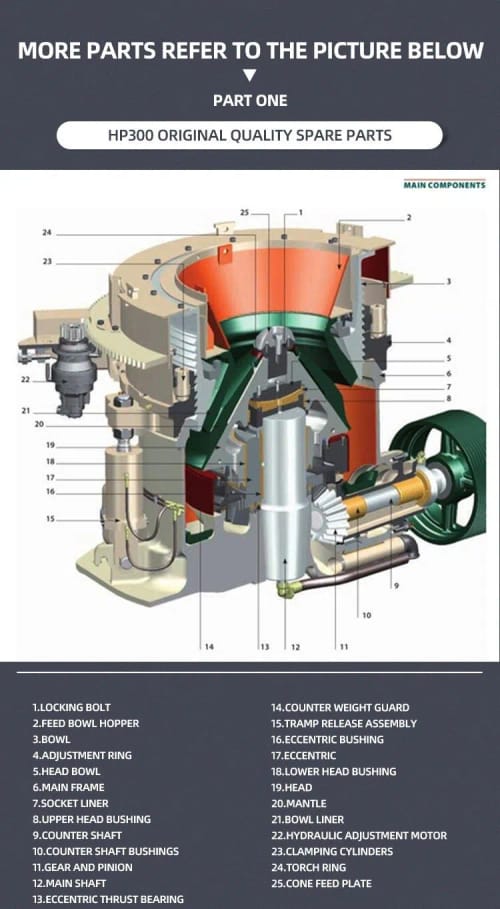

Hydraulic Cone Crusher Common Problems and Solutions! Hydraulic Cone Crusher is a new and advance type of cone crusher. Here is some key problems and probable solutions for users's reference. Stone production line is mainly composed of the vibrating feeder, Jaw crusher, Impact crusher, Vibrating screen, electronic control and Belt conveyors

Learn More

Repairing and Troubleshooting for Jaw Crusher (I

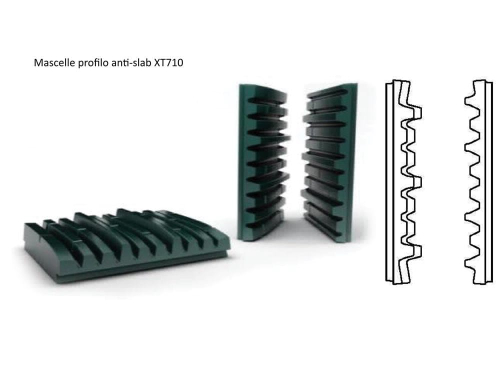

10/14 · The repair methods of the jaw crusher: (1) Check the wear condition of jaw plate.Jaw plate is made of high manganese steel casting. In order to increase the raw material crushing ability, working surface of jaw plate is cast into tooth form. When jaw crusher

Learn More

Common Faults and Solutions of Jaw Crusher

11/22 · Solution: there might be three reasons about this problem. Firstly, the undersize of the discharge opening causes the clashes of fixed jaw plate and movable jaw plate, which

Learn More

Cause Analysis and Problems Solving of Jaw Crusher

2022/3/22 · Next, we will introduce the failure analysis and troubleshooting of the jaw crusher. The main engine suddenly stopped Cause analysis: 1The discharge port is blocked, causing full

Learn More

Problems In Jaw Crushers - HN droled mine treatment equipment expert

5565 jaw crusher problems - Grinding Mill China. SBX cone crusher accepts COMPANY SOLVES ROCKY PROBLEM midsize jaw crushers models 1021 Thru 3042 model 3258 troubleshooting,

Learn More

Jaw Crusher Model I PULVERISETTE 1 classic line / Downloads

FRITSCH Jaw Crushers: pre-crushing of very hard, hard, medium-hard, brittle, tough, Operating manual Jaw Crushers PULVERISETTE 1 classic line.

Learn More

QJ340 Crusher Manual.book - Crushing Tigers

The Adjustment Procedure of The Jaw Closed Size Setting (CSS)- The QJ340 Crusher must not be operated until the manual and all

Learn More

What are the solutions for the common faults of jaw crushers?

The problem may be caused that the bearing bush is pressed too tightly, and the amount of pressing degree of the bearing bush can be adjusted by the gasket. Or

Learn More

Troubleshooting of jaw crusher - Knowledge - Handan Metallurgical

Troubleshooting of jaw crusher. Nov 21, 2021. It is common to see that the body of the hammer crusher that has been overhauled and installed for the first time vibrates strongly during the trial operation. There are several reasons for this situation:

Learn More

Methods of Jaw Crusher Troubleshooting (1)_ZK Ball Mill_Rotary Kiln

ZK is one of Chinese professional jaw crusher manufacturers, with more than 60 years' design and production experience of jaw crusher.There will be a lot of problem on the operation of jaw crusher, and the following will introduce the methods of jaw crusher troubleshooting.. Fault phenomenon 1. The main engine suddenly stop working (commonly known as: blocking run).

Learn More

Cone Crusher's Troubleshooting and Maintenance Measure

Crusher spring is not enough tightness; the ore uneven or excessive, the crusher will cause frequent vibration; When the crushed mine excessive and moisture,

Learn More