Roll Crusher - an overview | ScienceDirect Topics

Download as PDF. Set alert. About this page. Roll Crushers. In Mineral Processing Design and Operations (Second Edition), 2016. 6.2.3 Roll crusher circuit design. Roll crushers most

Learn More

Twin Roll Crusher (TRC) - Mark & Wedell

The Twin Roller Crusher (TRC) is opening, from where it is drawn into the crushing zone, by the two counter-rotating rollers.

Learn More

Roll crushers - SlideShare

DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support

Learn More

efficient crushing - double roll crusher

Double roll crushers are used for both, primary and secondary crushing. They guarantee a strictly de- fined final grain size with a minimum of fine grains.

Learn More

EXP-6,Roll Crusher.pdf - CHE1022: Mechanical Operation Lab

View EXP-6,Roll Crusher.pdf from CHE 1022 at Vellore Institute of Technology. CHE1022: Mechanical Operation Lab Expt No Date :6 : ROLL CRUSHER AIM: To find the power consumption, reduction ratio,

Learn More

HAZEMAG Roll Crusher | HRC - Rolling Rock Equipment

2021. 10. 1. · parallel retraction of the fl oating roll, the rocker arms are connected with each other over a torsion shaft. The rotational reaction of the fl oating roll allows an almost

Learn More

PDF) An Improved High-Pressure Roll Crusher Model for Tungsten and

Block scheme of the reformed Austin model [6,19] for several steps of comminution in high pressure roll crusher. f i j represents the feed for each sub-process, with i = 1. .. n, and n is the particle

Learn More

DOUBLE ROLL CRUSHERS

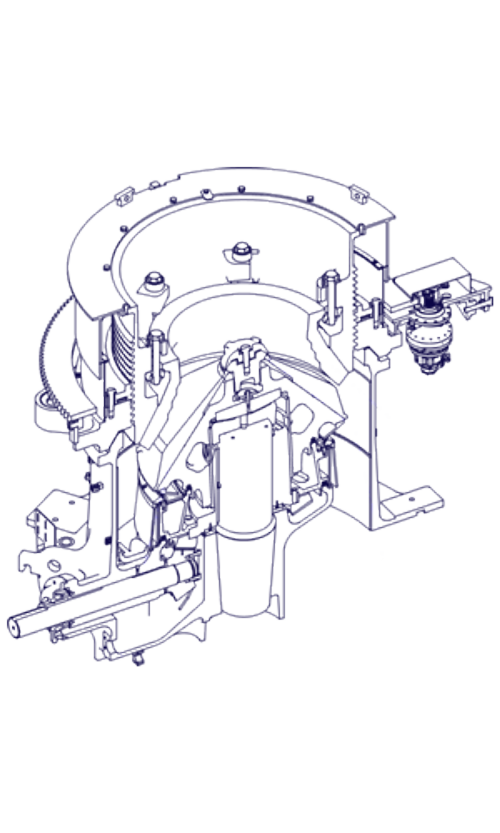

2018. 8. 20. · DOUBLE ROLL SPECIFICATIONS Sectional drawing of Double Roll Crusher fitted with smooth rolls Capacities, dimensions and weights will vary with the characteristics of each individual material. The details contained within this leaflet are for information purposes only and we reserve the right to change product specifications without prior notice.

Learn More

2PG SERIES DOUBLE ROLLER CRUSHER

2022. 2. 22. · 2PG SERIES DOUBLE ROLLER CRUSHER Feed size: up to 2500 mm (99 in) Product size: 80 to 400 mm (3 to 16 in) Throughput capacity: up to 12000 mtph (13228 stph) Reduction

Learn More

Roll Crusher - 911 Metallurgist

Its two dust extraction ports allow for safe removal of dust created in crushing samples. Roller gaps are adjustable to 2.54mm and access to drive components

Learn More

Construction, Working and Maintenance of Crushers for

For example, a single-roll crusher, employ shear together with impact and compression. Shear crushing is normally used under following conditions.

Learn More

PDF 2pg Series Double Roller CrusherPDF

Double roll crushers are used for both, primary and secondary crushing. They guarantee a strictly defined final grain size with a minimum of fine grains. Raw materials, secondary materials and by-products such as coke, sinter, coal, soft to medium-hard rock, ore, chalk, broken glass and similar products. Double roller crusher 2PG1012

Learn More

double_toothed_roll_crusher_br

Toothed Double Roll Crushers are used for crushing the friable and brittle materials like Coal, Coke, Sinter (hot and cold), Clay, Earth, Slag, Chalk, Soft

Learn More

Eccentric roll crushers ERC® - Thyssen Krupp

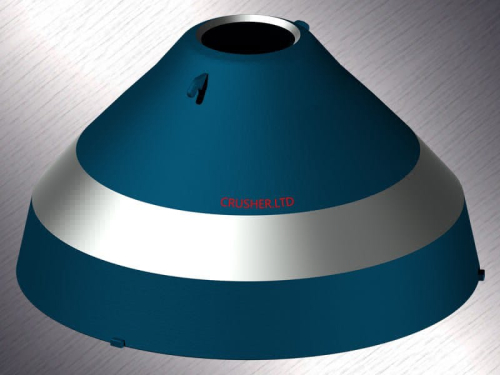

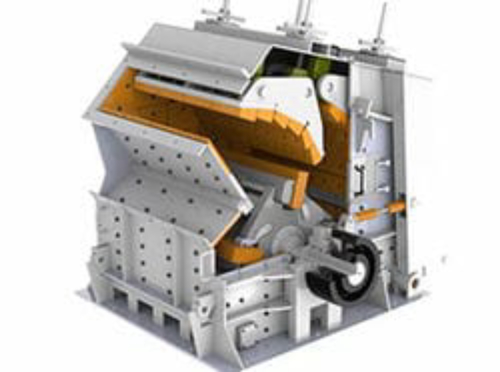

With its new eccentric roll crusher (ERC®) thyssenkrupp Industrial Solutions has developed a groundbreaking solution for the primary crushing of hard rock

Learn More

Roll Cruser Pdf

Figure 1: Double roll crusher geometry 2.1.5 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5]. For rolls that have equal radii and length, tangents drawn at. Double Roll Crusher - McNally Sayaji

Learn More

PDF Mining Technologies Eccentric roll crushers ERCPDF

1) Crusher capacity calculated based on a typical run-of-mine feed material with an average raw density 2.8 t/m³ and max. feed size ≤ 80 % of crusher feed opening. Actual values are depending on feed material characteristics (e.g. hardness UCS, feed particle size distribution, moisture content),

Learn More

Howto Size smooth Roll Crushers - RocketCDN

roll crushers produce very few fines and absolutely no oversize. The diameter ofthe rolls varies with the clearance between them, feed size, and the coefficient

Learn More

Roll crusher working principle | Henan Deya Machinery Co., Ltd

2021. 8. 20. · Figure 2 Toothed roll structure. B. Single roll crusher. The structure of the single roll crusher is shown in Figure 3. The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on the core of the roll, with the tip of the tooth sticking forward like a hawk’s beak, which can be removed and replaced when the

Learn More

Roll Crusher Pdf - manufacturer, factory, supplier from China

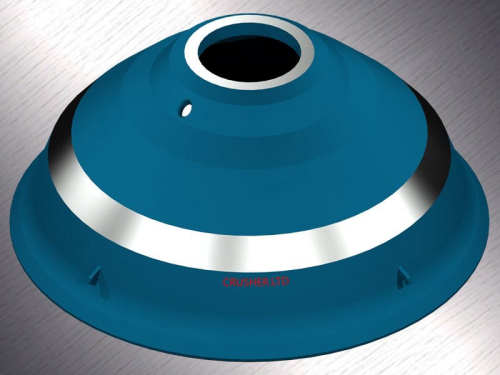

Total 24 Products for Roll Crusher Pdf) Roll Crusher Pdf - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Wire Rod Plant Rolling Mill Machine.

Learn More

Roll Crushers - ScienceDirect

Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm. The spring pressure for light duty rolls varies between 1.1 and 5.6 kg/m.

Learn More

How To Design Roll Crusher.pdf [vlr088qdgjlz]

DESIGN CONSIDERATION: Roll Crusher Type: Double Roll Crusher Material to be crushed: Bituminous coal, Broken Maximum Feed Size: 2 3/8 in. Distance Between rolls: 1 ½ in. Operating Condition: dry condition Further specifications and design considerations were made along the design process.

Learn More

Roll crusher | Henan Deya Machinery Co., Ltd

2021. 9. 16. · Roll crushers are arbitrarily divided into light and heavy duty crushers. The diameters of the light duty crushers vary between 228 and 760 mm with face lengths between 250 and 460 mm. The spring pressure for light duty rolls varies between 1.1 and 5.6 kg/m. The heavy duty crusher diameters range between 900 and 1000 mm with face length between

Learn More

PDF Handbook of Crushing - TerraSource GlobalPDF

The bottom of the Pennsylvania Crusher reversible impactor is open and the sized material passes through almost instantaneously. Liberal clearance between hammers and the breaker blocks eliminates attrition and crushing is by impact only. Pennsylvania Crusher single roll crushers reduce large input by a combination of shear, impact and compression.

Learn More

PDF High Performance Mixing & Pelletizing Technology - Lancaster ProductsPDF

Lancaster Model 48 x 32 Double Roll Crusher •Roll opening: 48" x 32" •Drive: 30 HP •Capacity: Up to 60 tons/hour •Each roll opening: 24" x 32" The Lancaster Model 24 x 32 Roll Crusher is made for long life with a minimum of maintenance. This crusher is designed to reduce, in a single pass, material previously requiring primary and

Learn More

PDF Design, Fabrication and Testing of a Double Roll CrusherPDF

Figure 1: Double roll crusher geometry 2.1.5 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5]. For rolls that have equal radii and length, tangents drawn at the point of contact of the particle

Learn More

PDF Construction Working and Maintenance of Crushers for Crushing Bulk ...PDF

For example, a single-roll crusher, employ shear together with impact and compression. Shear crushing is normally used under following conditions. When material is somewhat friable and has relatively low silica content. For primary crushing with a reduction ratio of 6 to 1. When a relatively coarse product is desired, top size usually larger

Learn More