Superior™ MKIII Series primary gyratory crushers - Outotec

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput Increased speed, installed power and mechanical improvements. Reduced downtime

Learn More

Gyratory Crusher Wear Parts - Columbia Steel Casting Co., Inc

Extensive experience with gyratory crushers around the world; Knowledgeable field service and engineering specialists; A "can-do" attitude about improving crusher performance; A manufacturer that can design and produce matched sets of crusher concaves and mantles in all sizes and alloy choices; Many heavy duty and custom designs available now

Learn More

Mantle Archives - Mayang Crusher Parts

Mantle - Mayang Crusher Parts. High quality and low price Mantle-Cone crusher wear parts

Learn More

EP0093069A2 - Anti-spin device for cone crusher - Google

B02C2/047 Crushing or disintegrating by gyratory or cone crushers eccentrically 4) The liner and mantle for the crushing bowl and the crusher head are

Learn More

SUPERIOR® gyratory crushers - Automation - PDF

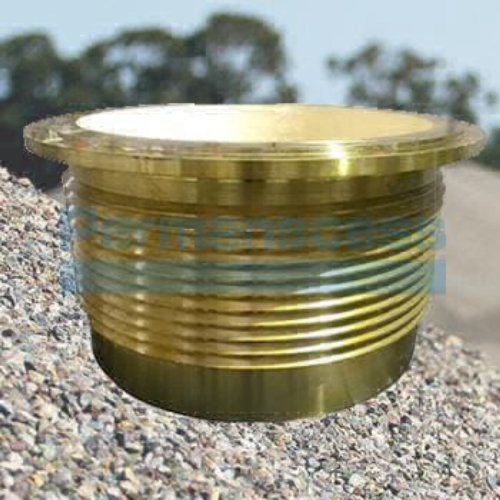

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, optimizing crushing performance 7 Patented headnut with burning ring allows for simple removal of the mantle 2 Manganese wearing parts are standard — chrome alloy option is available for concaves and bottomshell liners 8 High-strength shell

Learn More

Gyratory Crusher Liners

Increase your operation's efficiency with our expert knowledge and high-quality equipment. We are the OEM manufacturer of Gyratory Crusher Liners.

Learn More

Source The Ideal Wholesale gyratory crusher mantle

Create fine powders for industrial projects with crusher machines. Browse the gyratory crusher mantle range on for all types at wholesale

Learn More

Gyratory Crusher & Cone Crusher Mantle Differences

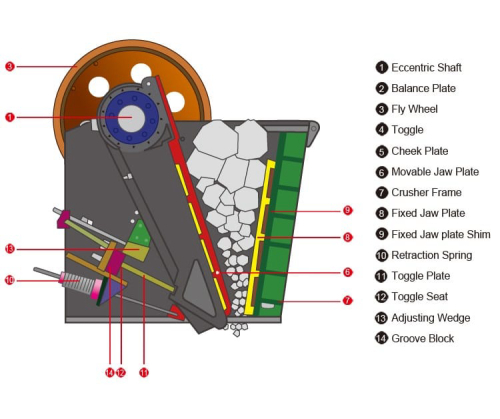

25/07/ · While the Secondary and the Tertiary crusher’s travels between 500-600 R.P.M. This difference in the speed results in a HAMMERING type crushing action over the SQUEEZING

Learn More

Torque Analysis of a Gyratory Crusher with the Discrete

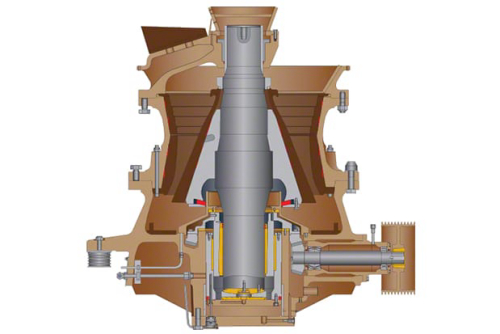

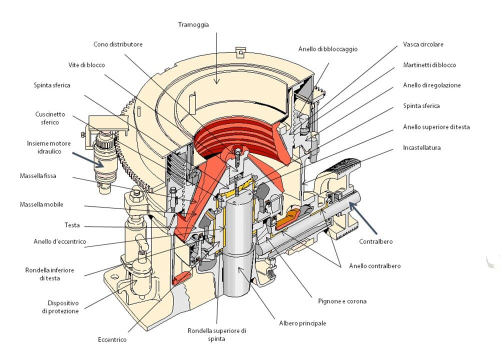

The functional principle of the machine is to compress the ore among the mantle and the concave. To achieve particle compression, the main shaft rotates

Learn More

CSP Gyratory Crusher Wear Parts

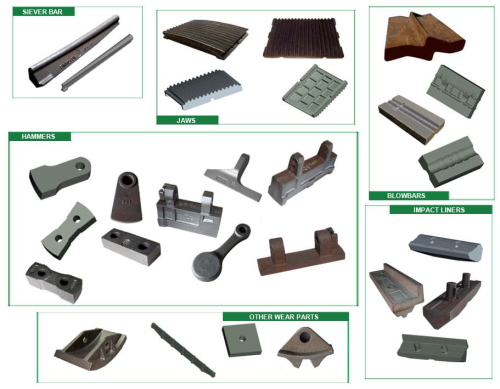

We offer high-quality replacement gyratory crusher wear parts, including: Liners Mantles Spider caps Spider arms Spider bushing Bottom shell bushing Pinion and gear Step bearings CSP manufactures concaves and mantles for Allis-Chalmers and Fuller/Traylor gyratory crushers. One-, Two- and Three-Piece Configurations are available.

Learn More

Gyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

Based on this design, our TIC insert mantle span life can be 2-3 times than normal manganese gyratory mantle. Gyratory Concave Designs We use the hardest alloy that will withstand the impacts of a specific gyratory application. This depends on the compressive strength, toughness, and friability of the material being crushed.

Learn More

Primary gyratory crusher parts - Outotec

Primary gyratory crusher spare parts. Outotec is the industry leader in manufacturing gyratory crushers with over sixty years of experience. As the popular crushers, our primary gyratory crusher spare parts are continually improved with upgrades and developments. Known for reliability, Outotec's spares for gyratory crushers are

Learn More

What is a cone crusher mantle? - Sandrock Mining

11/06/ · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have

Learn More

Crusher Closed / Open Side Setting Program - Global PAM's

is an automated closed side setting system for gyratory crushers that measures the gap between the concave and mantle.

Learn More

US4410143A - Main shaft assembly for a gyratory crusher - Google

As exemplified by U.S. Pat. Nos. 2,883,218 and 4,034,922, a gyratory crusher typically includes a main shaft provided with a tapered portion which supports the crusher head or mantle through a correspondingly tapered internal bore extending through the mantle.

Learn More

US3565354A - Gyratory crusher mantle-bowl structure - Google

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing hard rock ore. Each of the

Learn More

Gyratory Crusher - Design of mantle and concaves - Crushing, Screening

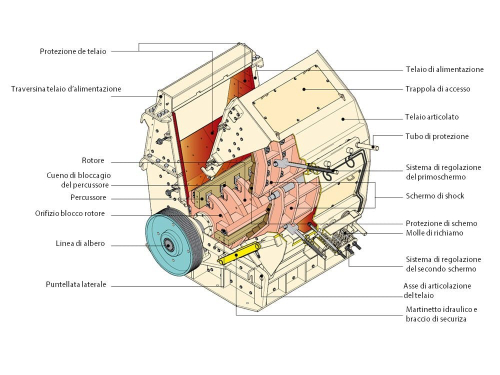

The majority of gyratory crushers are used as primaries, i.e. they receive the initial feed from the mine or quarry. The same type of crusher with chamber modifications is used as a secondary crusher, particularly when following a large primary crusher. The fine-reduction gyratory crusher can also be used for tertiary crushing.

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 2

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn More

Method for securing a gyratory crusher mantle - Google Patents

The mantle can loosen from the main shaft. If the gyratory crusher is not shut off, the free spinning mantle can cause extensive damage to the crusher. The

Learn More

Gyratory Crusher Wear Parts - Unicast Inc

Gyratory Crusher Concave Liner Segment Unicast Wear Parts. Gyratory Crusher Mantle Unicast Wear Parts. Gyratory Crusher Spider Cap Unicast Wear Parts.

Learn More

Gyratory crusher mantle-bowl structure - Google Patents

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing

Learn More

GYRATORY CRUSHER MANTLE-BOWL STRUCTURE - STOODY CO.

1. An improved mating mantle-bowl structure for a crusher wherein a drive unit provides a gyratory movement between said mantle-bowl structure to afford a crushing action, comprising: a mantle defined as a figure of revolution and including an externally defined conical section of substantially linear external taper and an external throat portion thereabove, said mantle comprising a base metal

Learn More

Gyratory Crusher Parts - Mayang Crusher Parts

Mining Industry Concave, Mantle, Bowl liner, Spider shield, Spider Cap. For over 35 decades, Mayang has applied the same engineering problem-solving to gyratory crushers which has proven so effective on cone crushers. We went into the field and studied the many areas for potential improvement: poor nip of feed material, excessive wear in the

Learn More

Gyratory Crushers - Mineral Processing & Metallurgy

17/02/ · Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″

Learn More

mantles on a gyratory crusher jacques jaw crusher upper thrust

Gyratory Crushers. Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle

Learn More

Crusher Concave Liners and Mantle Wear - Mineral Processing & Metallurgy

Soon the pattern that the ore takes through the crusher begins to change. This is due to wear causing a LIP to be formed at the bottom of the mantle. When the formation of this lip passes a critical point the force of the crushing action begins to be directed upwards restricting the normal flow of ore downwards.

Learn More