Gyratory Crusher Pro | manufactor | thyssenkrupp Mining

Jaw Gyratory Crusher Pro – the next generation of thyssenkrupp´s unique bestseller for crushing is now available. The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial

Learn More

Superior™ MKIII 42-65 primary gyratory crusher - Outotec

Superior™ MKIII 42-65 primary gyratory crusher provides high throughput and less downtime that is perfect for smaller operations. Higher throughput Increased speed, installed power and mechanical improvements. Reduced downtime New set of shells and concaves brings less downtime. Advanced automation

Learn More

Gyratory Crusher

HGT Hydraulic Gyratory Crusher is a primary crusher integrated mechanical, hydraulic, electrical, automated and intelligent control together. And the automatic control system

Learn More

Gyratory Crusher | Jaw Crusher Manufacturer | CITIC HIC

Technical Specifications Gyratory Crusher Jaw Crusher Semi-mobile Gyratory Crushing Station Single-cylinder Cone Crusher Multi-cylinder Cone Crusher Gyratory Crusher, PXZ Series New Type Gyratory Crusher, PXZ Ⅲ Series Case Study Swedish Mining Company LKAB Semi-mobile gyratory crushing plant trial run (PSZ3000) Swedish Mining Company LKAB

Learn More

Superior™ MKIII 60-89 primary gyratory crusher - Outotec

Features Superior™ MKIII 60-89 primary gyratory crusher provides increased throughput coming from increased speed and installed power that brings overall benefits to your primary crushing circuit. High throughput Reduced downtime Fast wear parts exchange Increased safety

Learn More

PDF 2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing EngineerPDF

The gyratory crusher, whether used as a primary or secondary. is essentially a gravity-type machine. Material flows vertically from top to bottom. It receives a large coarse feed, usually run-of-mine, and its product normally requires additional crushing before produc- ing the final product.

Learn More

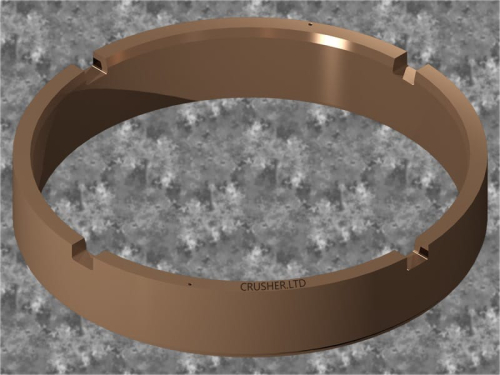

Gyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

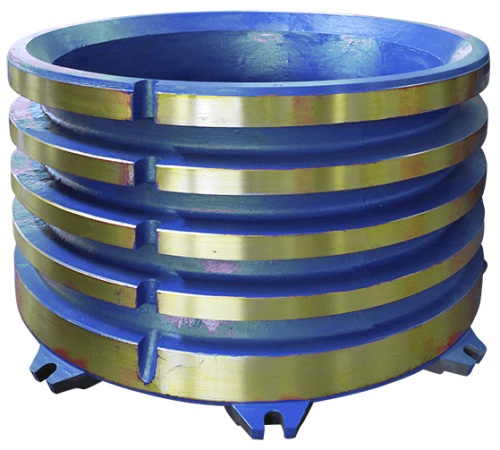

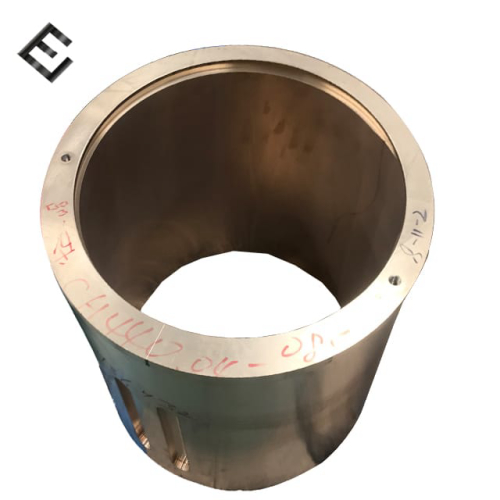

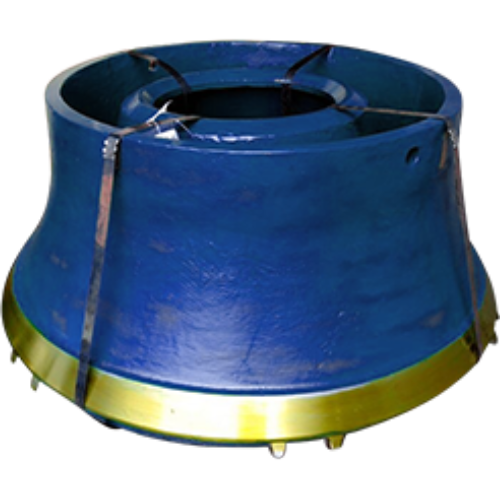

Alloy steel, TIC inserts, and manganese steel concave wear parts are designed for the hardest rock in surface and underground operations. Gyratory Mantle Designs Our many mantle designs range from smooth one-piece options to large, full-toothed, two-piece, or three-piece solutions. Teeth can be used at almost any level on mantles to improve nip.

Learn More

PDF SP50 GYRATORY CRUSHER - TerexPDF

SP50 GYRATORY CRUSHER Increased capacity, with reduced maintenance and downtime is what the SP50 Secondary Gyratory Crusher delivers. The SP50 features tramp iron relief via accumulator and relief valve, adjustable SPECIFICATIONS ® Jaques SP50 Gyratory Crusher Weight 29500 kg (65050 lbs) Maximum Capacity 650 MTPH (715 STPH) Motor

Learn More

Gyratory Crusher (Superior)

Rotary" crushers exploiting "gyration", are significantly developed due to their larger capacity compared to jaw crushers. This type of crusher consists of a concave surface and a conical head with the outer shell being pointed downward and the inner cone standing upward. The outer shell is fixed while the inner cone rotates.

Learn More

P&Q University Lesson 7- Crushing & Secondary Breaking

A gyratory crusher uses a mantle that gyrates, or rotates, within a concave bowl. As the mantle makes contact with the bowl during gyration, it creates compressive force, which fractures the rock. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength.

Learn More

Jaw Crusher VS Gyratory Crusher - JXSCMACHINE

Capacity Gyratory crusher can work continuously, has high productivity and crushing ratio ( up to 6-9.5), working performance is very stable, light vibration. Jaw crusher cannot work continuously, leading to lower productivity. Jaw crusher has a weakness that the cavity cannot be filled with material, a gyratory crusher has much flexibility.

Learn More

Gyratory Crusher Specifications And Performance

Gyratory Crusher Full Specifications. Specifications of a gyratory crusher with 2000 ton per day basic motor specifications begin with determining while a full gyratory crusher would have load torque re-rushing screening machine jaw crusher, rotary gyratory crusher,gyratory breaker,gyratory crushing machineyratory crusher product size cz-eu.

Learn More

2. GYRATORY CRUSHERS - Metallurgist & Mineral

The gyratory crusher, whether used as a primary or secondary. is essentially a gravity-type machine. Material flows vertically from top to bottom. It receives a large coarse feed, usually

Learn More

Gyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum

Learn More

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crush - ing chamber below.

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). – This crusher can handle products with a Mohs hardness that is not

Learn More

Crushers Specifications | Engineering360 - GlobalSpec

Find Crushers on GlobalSpec by specifications. Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of ra Cone / Gyratory Crusher Coarse crushers

Learn More

gyratory screen machine for quartz sand for food specifications

gyratory crusher pdf essential upper head bushing of a Carbonated Drink Filling Machine; Product Category. -ME07+ spring cone crusher head bush drawings sg4265 concave lock pin superior gyratory din 71412 standard pdf gyratory crusher specifications.

Learn More

PDF CG800i GYRATORY CRUSHER SERIESPDF

TECHNICAL SPECIFICATION CG800i GYRATORY CRUSHER SERIES CG800i crushers are built to be robust, reliable and efficient. Connected to My , they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. All to give you optimal reliability and drive down operating costs.

Learn More

gyratory crusher specs

Gyratory Crusher Equipment Specifications. Gyratory Crusher Models With Specifications.Gyratory crusher specifications allisosteodons.nl allis chalmers gyratory crusher specificat

Learn More

Gyratory Primary Crushers Specifications

3/13 · the gyratory crusher has capacities starting from 1200 to above 5000 th. to have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must

Learn More

Gyratory Crusher Lubrication - Mineral Processing & Metallurgy

7/18 · This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore carriers are dumping directly into the crusher. This means that the machinery is exposed to whatever climate it is being operated in. In hot areas the oil may have to be cooled while the opposite is true for the colder climates.

Learn More

gyratory crusher installation specification

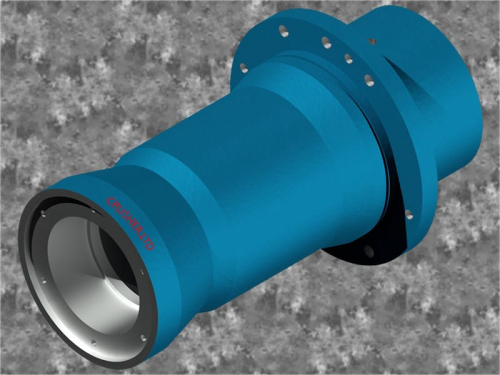

The benefits of our systems are numerous: high throughput coupled with low costs, minimum maintenance, ease of operation and maximum reliability. 2 Gyratory crushers 3. Gyratory crushers - design and operating principle Technical data Design A Spider bearing in two-armed spider ensures spacious feed opening, automatic lubrication with

Learn More

Minerals | Free Full-Text | Torque Analysis of a Gyratory Crusher with

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely utilized, and their reliability has become a relevant aspect. To optimize the design and to improve the availability of gyratory crushers, it is necessary to calculate their power and torque accurately. The discrete element method (DEM) has

Learn More

Gyratory Crusher, Technical Data | Crusher Mills, Cone Crusher, Jaw

Gyratory Crusher Specification. Gyratory cone crusher is crushing speed, eccentricity Technical Data; Working Principle; Projects; Gyratory Cone Crusher Structure: gyratory crusher datasheet - CGM Crushing Plant 9 y o s DAT SHEE TA ET SUPERIOR® 60‐89 MK‐II PRIMARY GYRATORY CRUSHER DATA Gyratory Crushers ,

Learn More

PDF Instruction Manual for Gyratory Crusher PXZ-1500IIPDF

The gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields. During its process of design and manufacturing, we take full account of the influence the equipment has on human health and safety. Although some accidents can Specification of crusher

Learn More