Rock Crusher Wear Plates | Project - Sketchart

Rock crusher wear plates. The rock crusher required refurbishment due to wear plates having been worn out. The crusher required the replacement of internal protection plates that had been used in extreme conditions. A 3D scan of the device was performed. and during this scan, a point cloud was obtained, which later on helped to create a 3D hull

Learn More

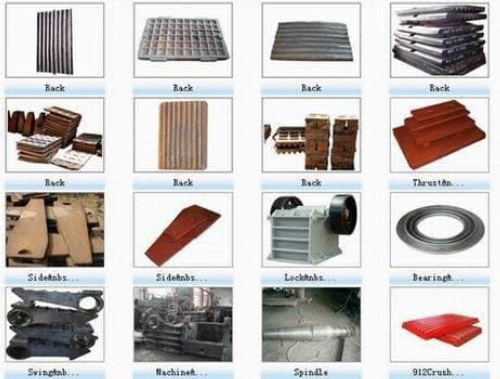

Jaw Plate For Sale | We Source Crusher Jaw Plates - Northern Crusher Spares

Jaw plates to suit crushers, Extec, Finlay and Fintec rock crushers. Northern Crusher Spares stock a wide range of jaw plate parts and replacements. We can also fabricate crusher parts for our customers. The rock remains in the jaws of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws.

Learn More

Jaw Crusher Toggle Plates vs. Hydraulic Toggle Relief Systems

A toggle plate basically operates like a fuse. If any material enters a jaw crusher that cannot be crushed, whether due to its size or composition, the toggle plate is meant to break, relaxing the moving jaw open to allow for the uncrushable material to fall through or be removed manually.

Learn More

Rock Crusher Wear Plate

From stone crushers to excavator undercarriage parts, buckets, and even drill bits to get you through the rocks, the rock crusher wear plate from Alibaba offers

Learn More

Aggregate Crushers, for Rock, Ore & Minerals - Gilson Co

Marcy ® Double Roll Crushers are used in intermediate size reduction of medium hard to hard materials such as rock or ore, and can bridge the gap between laboratory and production outputs. Models with 3,000lb per hour (1,361kg) or 8,000lb per hour (3,629kg) capacity reduce most materials from 0.5in (13mm) feed size to minus No. 10 (2mm).

Learn More

Manual Rock Crushers - Gold Prospecting Mining Equipment Detectors

The CrazyCrusher brand Rock Crusher is 100 percent steel, and it is 100 percent made in the U.S.A. by 100 percent Americans! The jaws are made of 3/8 steel, and the face has horizontal welds across them that not only help grip and pull down rock pieces, it also prevents we the actual jaws. On the moving jaw, vertical "teeth" were added to

Learn More

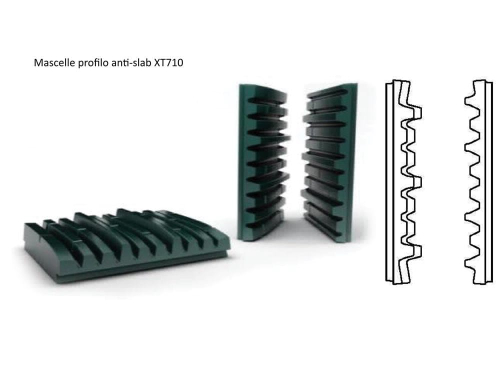

What are the Materials of the Jaw Crusher Plates and Which is

High manganese steel. High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher,

Learn More

New Rock Crushers - Mellott Company

Manufacturer: Outotec Inventory #: Features: Includes standard equipment of frame, pitman assembly, standard flywheels, cheek plates, jaws,

Learn More

Rock crushing spare parts jaw plate Manufacturers and Rock crushing spare parts jaw plate

China Rock crushing spare parts jaw plate Manufacturer & supplier, offer different kinds of Jaw Crusher Spare Jaw Plate,Crusher Parts Jaw Plate,Wear Parts Jaw Plate for customers. ZHEJIANG FULE MINING MACHINERY CO., LTD [Zhejiang,China] Business Type: Manufacturer , Trade Company

Learn More

Jaw Rock Crusher Supplies By Trusted Manufacturer - AGICO

The rock reduced by jaw crusher is ready for impact crusher and cone crusher to do the medium and fine crushing. Jaw crusher is currently the most common crushers for sale in the world. Equipped with high-manganese-steel jaw plates, it can crush ores, rocks, steel slag, and other hard materials.

Learn More

Crusher Jaw Plate Latest Price, Manufacturers & Suppliers

Jaw Plates ; Crusher Jaw Plate, For Industrial. ₹ 72/ Kg Get Latest Price · Vipin Engineering Works ; Manganese Steel Jaw Crusher Plate, Surface Coating: Matt

Learn More

Stone Crusher Jaw Plate Manufacturer from Coimbatore

Manufacturer of Crusher Plate - Stone Crusher Jaw Plate, Rock Crusher Jaw Plate, Crusher Side Plate offered by S. K. M. Engineering Works, Coimbatore,

Learn More

Crusher Jaw Plate for Sale - EB Castworld % Crusher Jaw Plate

Type: Jaw Plate / Crusher Plate; Machine Type: crusher / Jaw crusher; Applicable Industries: Energy & Mining; Manganese Contents: Mn13Cr2, Mn18Cr2, Mn22Cr2, etc; Features & Advantages: Materials: High manganese or other materials as your requested. Use: Wear parts for crushers in the quarry, mining, construction and metallurgical industry

Learn More

Hillsboro Hillsboro Oregon Aluminum License Plates - CafePress

Shop Hillsboro Hillsboro Oregon Aluminum License Plates from CafePress. Find great designs on durable and weather resistant License Plates to make your car stand out! Free Returns 100% Satisfaction Guarantee Fast Shipping (844) 988-0030. Track Order. Help Center. Sign In | Join. Hi, Hi! Member # My Account;

Learn More

GME10 - Jaw Rock Crusher - Global Mining Equipment

The jaw rock crusher wear plates are 3/4" (19mm) and are made of a hard faced 450 Brinnel Hardness Material. Also available is an upgraded cast manganese /

Learn More

rock crusher plates

The product from this crusher is generally liberated enough and ready to pan or table for gravity gold separation. When you buy this Small Rock Crusher, you also get: An operating manual, the pulley, pre-installed AR450 jaw plates. Without the 1 HPmotor or mounting frame. This crusher canoperate with gas/diesel engine as well as electric motor.

Learn More

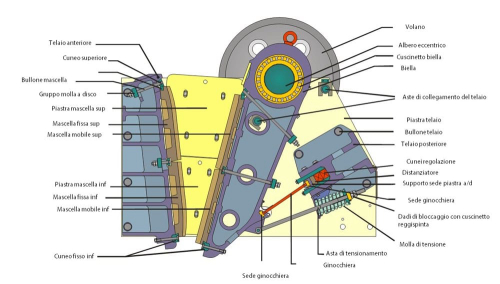

Design and Finite Element Analysis of Swing Jaw Plate of

Abstract stiffness of swing plates has not been varied with changes in rock Point load-deformation relationships and design of jaw crusher plates.

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Jaw Crusher For Sale | Jaw Rock Crusher Supplies By Trusted

The rock reduced by jaw crusher is ready for impact crusher and cone crusher to do the medium and fine crushing. Jaw crusher is currently the most common crushers for sale in the world. Equipped with high-manganese-steel jaw plates, it can crush ores, rocks, steel slag, and other hard materials. It can be used in cement plants, quarries, stone

Learn More

Jaw Crusher Accessories - Armstrong Industries

Our rock crushers are built super tough so they withstand some of the countries most hardened and abrasive JPF JC100x60 - Jaw Plate Fixed for JC 100x60.

Learn More

Scott | Rocklabs BIG BOYD

Resources. The BOYD Crusher is the world’s first double-acting, fine jaw crusher. Its design includes top and bottom driven moving jaws, enabling the maximum amount of crushing in a single pass. The Big BOYD Crusher takes lump sizes of up to 150mm pieces and crushes them to 10mm or less in a single pass, reducing time for every sample.

Learn More

Rock Crusher Machines & Pulverizers | Williams Crusher

The Williams Traveling Breaker Plate Mill is suitable for clay and muddy rock crushing. The breaker plates on this hammer mill continually “travel” while in use with all slack on the away

Learn More

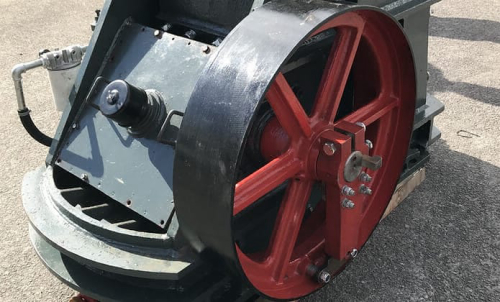

Crusher - Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, undergoes two types of motion- swing motion towards the fixed jaw due to the action of toggle plate and vertical movement due to the rotation of the eccentric. These two motions

Learn More

Jaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

Our customers have proven that the right jaw plate design can make a dramatic difference, depending on the application. We have many case histories in which

Learn More

Jaw Crusher - Eastman Rock Crusher

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary

Learn More

Crusher Wear Parts for Popular Crushers | Columbia Steel

Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and abrasion your crushers encounter, resulting in better overall plant performance. For gyratory, cone, jaw, hammer mill, impact

Learn More