Gyratory Crusher Mantles - Columbia Steel Casting Co., Inc

Our many mantle designs range from smooth one-piece options to large, full-toothed, two-piece or three-piece solutions. Teeth can be used at almost any level on

Learn More

the effect of liner we gyratory crushing – a dem case study

PDF | Gyratory crushers are frequently used for first stage sizing in the concave and mantle liner we gyratory crusher production.

Learn More

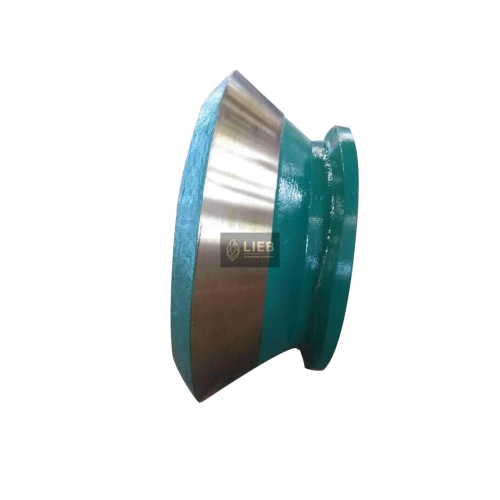

Cone Crusher Mantle Latest Price, Manufacturers & Suppliers

MS Cone Mantle The range of MN content which we can offer in concave mantle as according to the customer is between MN - 10% to 24%, cr - 1.5% -3% and the

Learn More

Gyratory crusher mantle design - Pinterest

Dec 23, - BDI Wear Parts is a dynamically growing company with many years of experiences in production and supply Crusher wear parts, Crusher spare

Learn More

Gyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn More

Source The Ideal Wholesale gyratory crusher mantle

Gyratory Crusher Mantle · High Manganese Steel Gyratory Cone Crusher Spare Parts Mantle And Bowl Liner · Gyratory Crusher Wearing Parts Mantle Mining Machinery

Learn More

Gyratory crusher mantle-bowl structure - Google Patents

Particularly formed telescopically mating conical elements (mantle and bowl) are disclosed for use in a cone type gyratory crusher as employed for reducing

Learn More

Crusher Closed / Open Side Setting Program - Global PAM's

Open pit mining worldwide utilizes gyratory crushers as the primary crushing circuit that feeds the mills. In some cases, the mantles are changed approximately

Learn More

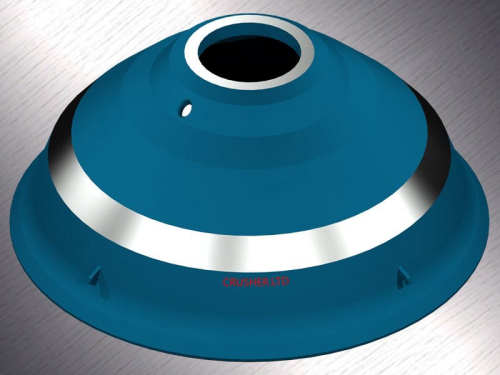

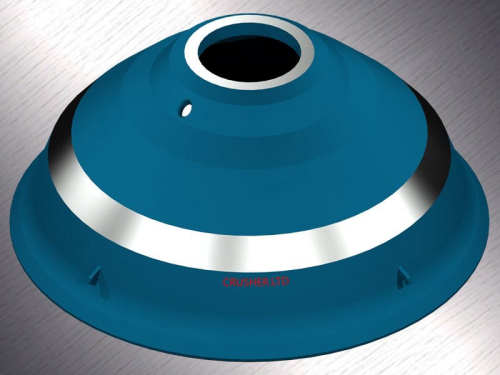

What is a cone crusher mantle? - Sandrock Mining

6/11 · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn More

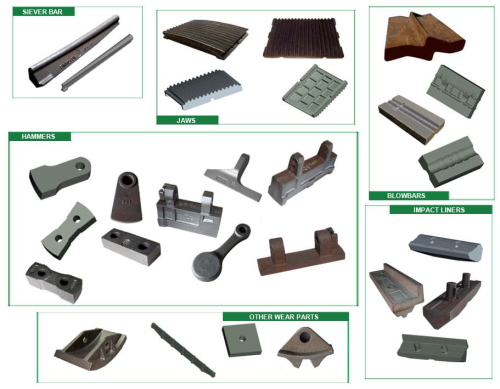

Gyratory Crusher Wear Parts - Unicast Inc

Unicast's gyrator crusher liners, mantles, spider caps, and spider arms are engineered to significantly extend wear life versus original equipment using

Learn More

China Primary Gyratory Crusher Mantle Liners

Primary Gyratory Crusher Mantle Liners ; Application. Quarry, Ore Mining, Cement, etc. ; Advantage. Good Wear Resistance ; Guarantee. Same as Original.

Learn More

IMPROVING GYRATORY CRUSHER PERFORMANCE - H-E

each mantle. Since H-E Parts improved the material selection and implemented a mantle and concave redesign, the following has been achieved:.

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

Gyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing. Major components can be divided to ease transport

Learn More

Gyratory Crusher & Cone Crusher Mantle Differences

The other most noticeable change is the crushing action of the mantle. In the Gyratory all the movement is in the bottom of the crusher mantle.

Learn More

rebuild mantle gyratory crusher | GP330 part

Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Mantle.

Learn More

gyratory crusher mantle manufacturing | small lab stone crushers

Gyratory Crusher & Cone Crusher Mantle Differences Jul 25, · In the Gyratory all the movement is in the bottom of the crusher mantle. This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the

Learn More

Gyratory Crusher Components - 911 Metallurgist

The mantle which is the movable working surface, is pivoted at its top within a spider bearing under the cap of the spider arm assembly while

Learn More

GYRATORY-CRUSHERS.pdf - RocketCDN

3) hydraulic piston. basically the frustum of an inverted cone. A movable crushing surface called the mantle, also conical in shape, gyrates within the

Learn More

mantles on a gyratory crusher C80 TOOL KIT C80 ER.904466

Gyratory Crusher Mantles Material Selection Jan 25, · Three Kinds Materials For Gyratory Crusher Mantles. 1. Manganese Steel. There are three kinds of manganese steel (Mn14,

Learn More

Gyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

A mantle for a gyratory crusher having a generally truncated conical shape and having a lower portion that is subjected to greater crushing stress than the upper portion. The upper surface portion has at least one groove which is concentric with the axis of the mantle. During crushing operations, the mantle will grow due to the stresses applied

Learn More

mantles on a gyratory crusher trunnion bearing on cement mills

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn More

mantles on a gyratory crusher jacques jaw crusher upper thrust

Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an oscillating shaft. The

Learn More

Method for securing a gyratory crusher mantle - Google Patents

The mantle can loosen from the main shaft. If the gyratory crusher is not shut off, the free spinning mantle can cause extensive damage to the crusher. The

Learn More

mantles on a gyratory crusher largest crusher discharge particle

Stone Crushing Plant Aggregate crushing plant Sand Manufacturing Plant Mineral Ore Processing Plant Construction waste recycling plant Accessories Vibrating feeder Vibrating screen Belt conveyor Sand washing machine Magnetic Separator Screen and

Learn More

mantles on a gyratory crusher S&H6800 Spare Part

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn More