Blue Crusher Liners | Crusher Mills, Cone Crusher, Jaw Crushers

Crusher spare part,Ball mill liner, Liner plate,High manganese steel,Ball mill spare part. 1.Brand Name: SHWJ 2.Use: Ore Mining 3.color: blue/as your order 4.Port animal feed crusher in Karnataka,India | Solution for Mining

Learn More

Cone Crusher Wear Parts - Columbia Steel Casting Co., Inc

For better production and longer wear life, choose Columbia cone crusher liners. · Standard, heavy-duty, and custom wear parts for all popular cone crushers.

Learn More

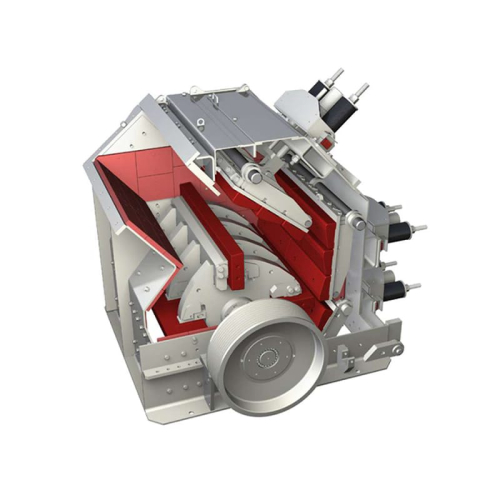

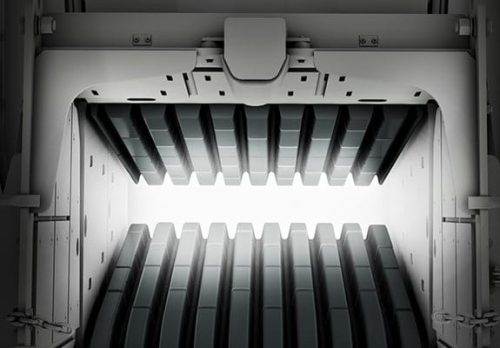

HAMMER CRUSHER | Crushing/Grinding

Product size can be adjusted easily by;. Changing rotor speed. Changing gap setting between hammer and grinding path liner. Using always new face of hammer by

Learn More

Linebacker® Crusher Liner Epoxy

Linebacker® Standard Crusher Liner Epoxy. For use in the majority of crushing applications with average strength ore, the Standard Crusher Liner Epoxy is designed for smaller cone crusher applications, typically crushing aggregates and other soft-to-medium hardness materials.

Learn More

Shell Liners | Crusher and Mill Liners | CITIC HIC

CITIC HIC has a wear liner production base with annual capacity of 30,000 tons of wear-resistant castings. At the production base, we can produce a variety of wear liners for crushers, grinding mills and vertical stirred mills. Through from casting process design, mold making, smelting & casting, heat treatment, quality inspection, to packaging

Learn More

Geometric analysis of cone crusher liner shape

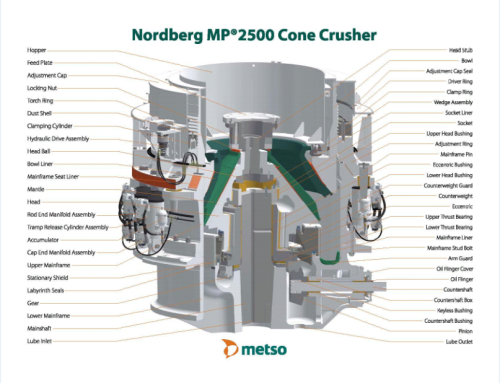

Cone crushers are in common use wherever crushing is required. Cone crushing for aggregate production far exceeds all other applications

Learn More

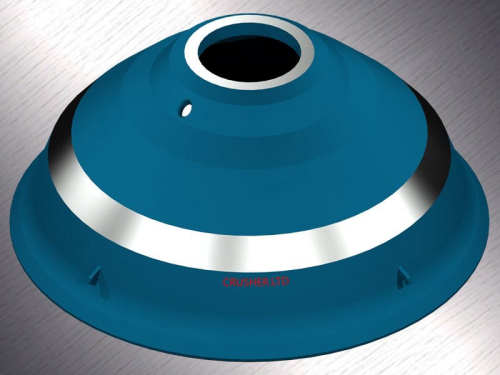

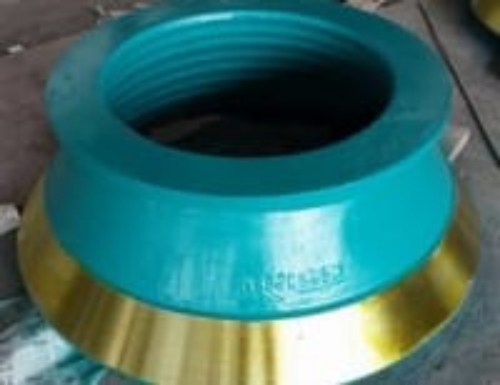

Bowl Liner - Casteel Foundry

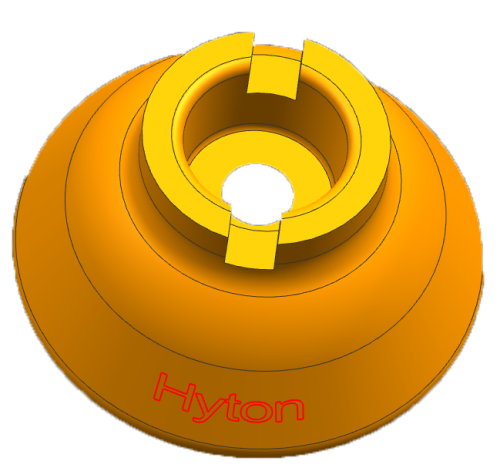

Mining Cone Crusher Parts: Items: Concave, Mantle, Concave Ring, Concave Segment , Bowl Liner,Cone Liner,Arm Guard, Distribution Plate Casting Material: Austenstic Manganese Steel (M14Cr2, Mn18Cr2, Mn22Cr2) Casting Method: Water Glass Sand Casting A

Learn More

Crusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

What We Offer, Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts,

Learn More

Crusher Liner Solutions - Bradken

Bradken Is A Leader In The Design, Manufacture And Supply Of Crusher Liners For Primary And Secondary Applications In The Global Mineral Processing And

Learn More

Material Used For Crusher Liners - Qiming Machinery

8/30 · Titanium Carbide. It is another renowned material used to manufacture crusher liners. Titanium carbide comes with amazing wearable characteristics that make it a good option for crusher liners construction. Liners that are made of titanium carbide last 2 to 4 times more than normal manganese steel liners.

Learn More

Crusher Liner Glue | Crusher Mills, Cone Crusher, Jaw Crushers

640-5439-0000, Heavy Duty stone Pill Crusher – 64-5439 . Mabis DMI Healthcare Pill Crusher, 2" x 3 -1/4 . Torbot Group Inc Skin Tac "H"™ Adhesive Barrier . First Quality Prevail® Pant Liner Elastic Large .

Learn More

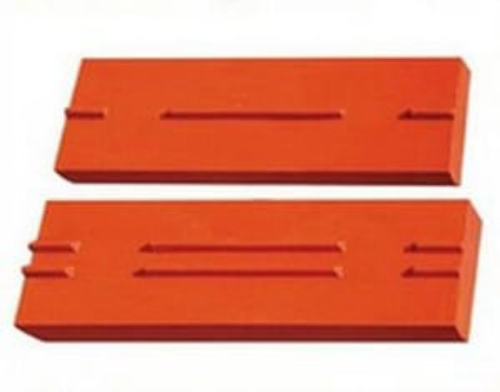

Crusher Liner Plates for High Chromium - EB Castworld

Crusher Liner Plates for High Chromium. Material: High Chrome Cast Iron & Ni Hard White Iron. Dimensions: as per drawings. Special Features: We adopt Sand Cast Process to make High Cr & Ni hard mill machine cooling plate. We do quenching & tempering treatment for high Cr & Ni hard white iron plates to achieve high hardness.

Learn More

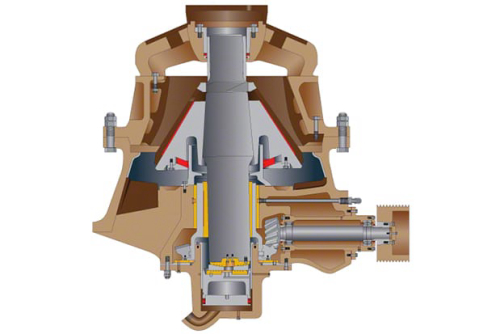

Common Faults and Solutions of Cone Crusher

6. Strong vibration of cone crusher The reason The device base fixture may be loose. There are hard-to-crush materials in the crushing cavity of the cone crusher. Too much material in the crushing cavity causes blockage. The liner is broken or worn. Solution

Learn More

Choose Your Location - rv.campingworld.com

The estimated monthly payment calculated above is for informational purposes only and does not constitute an advertisement for any terms, an actual financing offer, nor any comm

Learn More

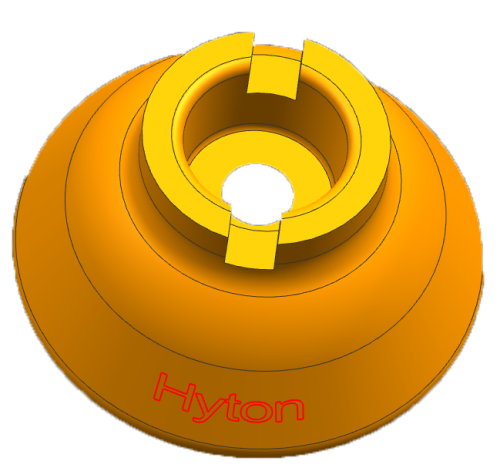

What is a cone crusher mantle? - Sandrock Mining

6/11 · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn More

Change Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use of

Learn More

Cone Crusher Liners: How to Select and When to Change

Choosing the correct liners and knowing when to change them is critical for optimal Cone Crusher performance.

Learn More

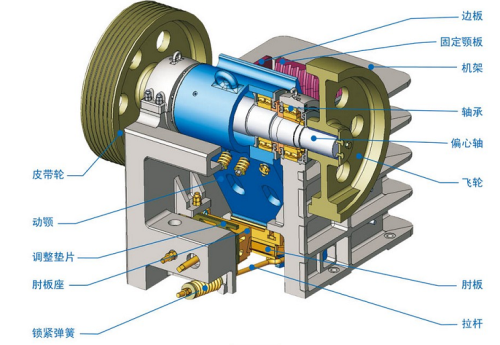

PDF R Crusher Wear Parts Reference GuidePDF

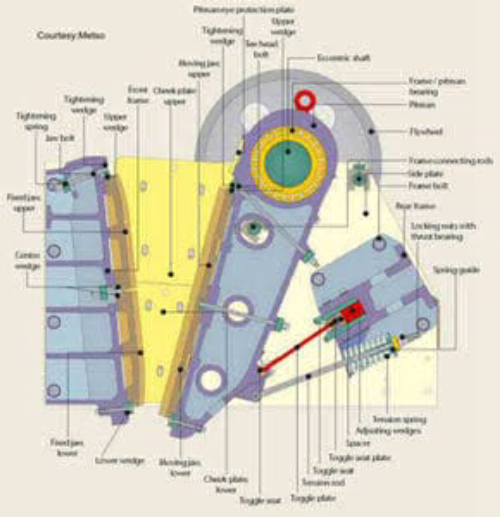

Between a jaw liner and crushing material . During this process small materials from each element become detached . Primary factor in wear for Crushing applications is ABRASION. Material fatigue is also a factor as the crusher tools E.G. Jaw liners are subject to numerous pressure and impact stresses.

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

Cone Crusher Liners - Makuri Group

Makuri provides real solutions for cone crusher liners that go above and Optimized secondary crushing improves overall plant throughput and reduces TCO.

Learn More

Change crusher liners - Wear Parts For Industry | Qiming

It is an important thing when to change crusher liner, so as to avoid damage to the liner seating surfaces of the crusher bowl, concave and mantle must be replaced before they are worn

Learn More

Crusher liner plate – Jordan Anwar Est

Crusher liner plates are part from a crusher , they are significantly higher in carbon and manganese. they are too heavy so they can break and crush almost

Learn More

Prolonging Cone Crusher Liners Working Life - Precision Casting

The chamber is lined with wear components, cone crusher wear parts namely the mantle and concaves. As the stone drops though the choked chamber, squashing is attained when the motion of the mantle causes compressive and abrasive pressures to act upon the stone and also dish liner, creating the rock to damage.

Learn More

Tips For Buying Crusher Wear Liners - Qiming Casting

Crusher wear liner replacement is probably one of the most important areas and decisions here can have a significant influence on the cost per tonne produced. When decision time comes to buy replacement manganese steel wear liners for your plant, it is important to choose the right crusher wear liner manufacuturer .

Learn More

Linebacker® crusher liner epoxy

Enables the proper seating of liners, maximising both liner and crusher body life. Page 2. M 10-18 7000-5-ENG www.flsmidth.com.

Learn More

CME™ Crusher Liners - H-E Parts

CME™ Gyratory Crusher Liners. H-E Parts also specialize in the design and manufacturing of CME™ gyratory concaves in both manganese and liquid quenched Ni-Cr-Mo steels that have been proven to provide longer, more consistent life than most common air-quenched concaves, with far less risk of failure that can be encountered with white irons.

Learn More