Mechanical analysis of local cutting forces and transient state

Workpiece. Workpiece. Chip. ECE. Ff f fi c i ci on cutting forces had been observed, it should be mentioned.

Learn More

Machinability and The Specific Cutting Force for Work-piece Materials

Two sets of factors are the condition of work-piece materials and the physical properties of work-piece materials. The condition of the work-piece material includes eight factors: microstructure, grain size, heat treatment, chemical composition, fabrication, hardness, yield strength, and tensile strength.

Learn More

Key to model-based machining: specific cutting force | Sirris

In addition to the material, the specific cutting force is also influenced by the chip angle. For example, there is a rule of thumb that for every degree that the cutting edge becomes more positive, 1.5 percent less force is required to form a chip. This rule of thumb is instinctively supported, as a sharp knife cuts easier.

Learn More

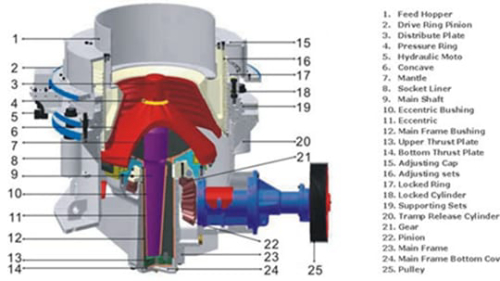

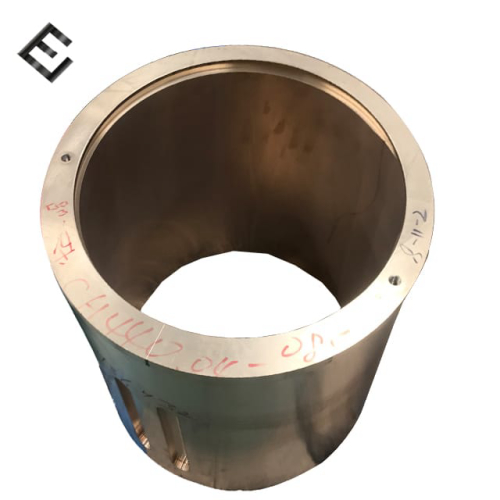

GP200S PROTECTION BUSHING G3310908160 why do you need to know the

Gac Motor. Welcome to the fascinating world of GAC MOTOR, built on quality, innovation, refined design and responsibility. Explore your favorite sedan, SUV or minivan across our premuim lineup.

Learn More

How Plasma Cutting Works and What Is Plasma Cutting - WeldingPros

It allows you to effectively process a high-quality blank for thick and medium sheet metals. Plasma arc cutting is ideal for the automation of the cutting process. When plasma arc cutting underwater - it creates a very low level of noise and produces a very low heat exposure too. Image of Plasma Cutting torch.

Learn More

Lecture 15: Material Removal Processes - Cutting Flashcards | Quizlet

Workpiece material is brittle or contains hard inclusions and impurities Specific Cutting Force. Ratio of the cutting force to the cross sectional area being cut. How do you increase the cutting force?-Increasing the strength of the workpiece material

Learn More

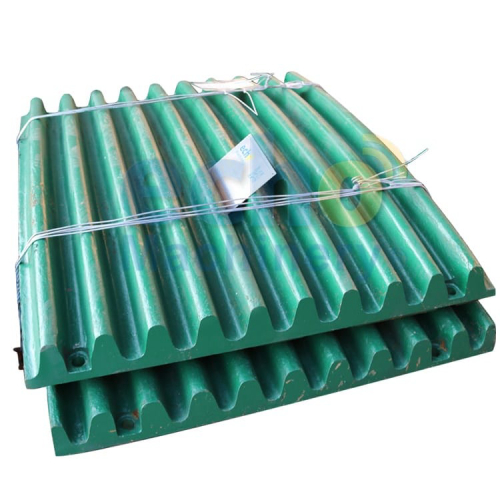

C80 JAW, FIXED QUARRY 1P why do you need to know the specific cutting

Lubrication Technologies Your Professional Lubrication Management Team. T +86-21-51393804 Email: [email protected] Lubrication Technologies, Inc. 120 BOSWORTH ST. WEST SPRINGFIELD • MA 01089

Learn More

The Impact of Cutting Tool Materials on Cutting Force

Keywords—hard turning, cutting force, cutting tool materials, I. INTRODUCTION high hardness of the workpiece, it results in higher cutting forces

Learn More

Fundamentals of Machining - IIE

workpiece surface finish and integrity, tool life, force and power 21.17 Why do you think the maximum temperature in orthogonal cutting is located at.

Learn More

HC84 SEAL OIL, PINIONSHAFT | why do you need to know the specific

Jun 29, · Well I found a oil leak . The Oil is coming out the brake pedal shaft. I would like advice if you have changed them, there are 2 but only one is leaking at this time. But I bet both will once the grease gets loosen up. The way it looks to remove the

Learn More

Lecture 15: Material Removal Processes - Cutting

Workpiece material is brittle or contains hard inclusions and impurities Specific Cutting Force. Ratio of the cutting force to the cross sectional area being cut. How do you increase the

Learn More

Cutting Forces in Turning Operations - UPCommons

In machining, the material of the workpiece used should be taken into account in order to predict the forces and reactions that the cutting operation will

Learn More

Cutting Speed Chart for Different Materials in Turning, Drilling and

Cutting speed, also known as surface speed, refers to the speed at the outside edge of the tool as it is cutting. It is measured in surface feet per minute (SFM). Cutting speed is mainly depending on the type of materials and cutting tools, related to their hardness. The harder the material, the slower the cutting speed should be.

Learn More

Cutting Formulas | Machining Formula Collection - KEYENCE

lm (mm): Length of workpiece. l (mm/min): Machined length per minute. memo. This formula is used to calculate the machining time from the length of the workpiece and the spindle speed. Example: Feed (f) = 0.2 mm/rev. Spindle speed (n) = 1100 min -1. Length of workpiece (lm) = 120 mm. First, the machined length per minute is calculated, in this

Learn More

Power-Based Estimation of Cutting Forces During Turning of

specific cutting force coefficients and cutting forces of the composite were estimated using C45 carbon steel as the workpiece material.

Learn More

TX303 ABC-MC-LT BLADE why do you need to know the specific

Niwalker Taser Schock Taschenlampe choque (SUPER SALE) USD 127.98 | Buy Cheap Niwalker Taser Schock Taschenlampe choque defesa pessoal selbstverteidigung 3500 Lumen 18650 Linterma Led MM6S (cG) 303LT Mini Wiederaufladbare.

Learn More

Dependence of the Cross Section of the Cut Layer on the

the cut layer of material and its influence on the specific cutting resistance. Keywords: nickel alloy, machining, cutting tool, cutting force, cutting.

Learn More

Workpiece Material Influence on Stability Lobe Diagram

Jan 01, · The workpiece material is a characteristic settled form the drawings that cannot be changed. Due to this, in which extent the SLD (Stability Lobe Diagram) is affected by the workpiece material

Learn More

Specific Cutting Force - an overview | ScienceDirect Topics

The specific cutting force coefficients depend on the part material and the substrate, coating, rake angle and helix angle of the tool.

Learn More

hp100 | why do you need to know the specific cutting force

Wanted Equipment – FindEQ. You want to sell your Used Equipment? Just send a Whatsapp or E-mail with details and photos of the machine (s) you want to sell. Do not forget to include your

Learn More

Determination of specific cutting force components and exponents when

The increase in force has an impact on the workload and tool life of the Workpiece-Fixture-Machine Tool-Cutting Tool (WFMC) system. Therefore, in applying the Kienzle and Viktor relationship to calculation of the cutting force, we need to know the change in the specific cutting force (kc1.1) and the exponent related to it (z) in cases where a

Learn More

Analysis cutting forces and surface roughness of fibre

composite workpieces material. Cutting force is one of the cutting conditions that can determine the machinability of the workpiece.

Learn More

SEALPLATE, SWING JAW 1312 | why do you need to know the

Optitooth jaw plate. On January 1 Mining and Rock Solutions Division Crushing and Screening became a business area of its own within Group. We are called Rock Processing Solutions and you'll find all our products within Stationary Crushing and Screening, Mobile Crushing and Screening and Attachment Tools (Breakers) on

Learn More

cone crusher parts | why do you need to know the specific

Whether you need to replace the mainframe liners, the hydraulic cylinders, or the socket sealing rings Excel has your Cone Crusher parts need 4ft Cone Crusher Parts, Feed Distributor 3041-5265

Learn More

Cutting Speed Chart for Different Materials in Turning, Drilling

Apr 20, · Cutting speed, also known as surface speed, refers to the speed at the outside edge of the tool as it is cutting. It is measured in surface feet per minute (SFM). Cutting speed is mainly depending on the type of materials and cutting tools, related to their hardness. The harder the material, the slower the cutting speed should be.

Learn More

Estimation of the specific cutting pressures for mechanistic cutting

The cutting force signal is simulated for the location of the cutter with respect to the workpiece shown in Fig. 5. This location of the cutter and workpiece corresponds to four pairs of entry–exit angles. The cutting force signal was simulated based on the multiple insert specific cutting pressure constants from Table 6.

Learn More