Types Of Gears [Classification of Gears] and Gear Trains

Spur gear; Helical gear; Double helical gear; Bevel gear; Spiral bevel gear; Screw gear; Mitre gear; Worm gear; Internal gear; Rack and pinion

Learn More

GEARS Lecture 1 - INTRODUCTION Contents - ResearchGate

1.3 Types of gears and their applications. 1.4 Spur Gear. 1.5 Helical Gear. 1.6 Double helical or Herringbone Gear. 1.7 Internal Gear. 1.8 Rack and pinion.

Learn More

PDF Back to Basics - Gear Design - Gear TechnologyPDF

A gear can be defined as a toothed wheel which, when meshed with another toothed wheel with similar configura-tion, will transmit rotation from one shaft to another. Depending upon the type and accuracy of motion desired, the gears and the profiles of the gear teeth can be of almost any form. Gears come in all shapes and sizes from square to

Learn More

Types of Gear Box | PDF - Scribd

of 5 TYPES OF GEAR BOX PROGRESSIVE TYPE GEAR BOX (Sequential Gear) • Usually this gear boxes are used in motor cycles. • In this gear boxes the gears pass through the intervening speeds while shifting from one speed to another. • There is a neutral position also present. • These gear boxes are a combination of sliding and constant mesh gear boxes.

Learn More

Introduction - University of Northern Iowa

Gear Types Spur gears Internal gears Most common form Used for parallel shafts Suitable for low to medium speed application Relatively high ratios can be achieved (< 7) Steel, brass, bronze, cast iron, and plastics Can also be made from sheet metal August 15, 2007 10 Gear Parameters Number of teeth Form of teeth Size of teeth

Learn More

Types Of Gears Pdf - signsascse

Types Of Gears Pdf. 11/29/ 0 Comments Within the spiraI bevel gears, thé one with thé zero twisting angIe is called zeroI bevel gear.By meshing a pair of these elements, they are used to transmit rotations and forces from the driving shaft to the driven shaft.Gears can bé classified by shapé as involute, cycIoidal and trochoidal géars

Learn More

Chapter 13 Gears – General Lecture Slides

Types of Gears Standardized Tooth Systems (Spur Gears) A rack is a spur gear with an pitch diameter of infinity.

Learn More

PDF Module 2 - GEARS Lecture 1 - INTRODUCTION ContentsPDF

1.3 Types of gears and their applications. 1.4 Spur Gear . 1.5 Helical Gear . 1.6 Double helical or Herringbone Gear . 1.7 Internal Gear . 1.8 Rack and pinion . 1.9 Bevel Gear

Learn More

ELEMENTS OF METRIC GEAR TECHNOLOGY

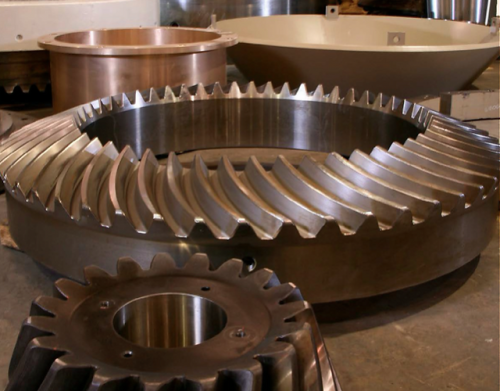

Double Helical Gear. Straight Bevel Gear. Spiral Bevel Gear. Zerol Gear. Worm Gear. Screw Gear. Hypoid Gear. Categories of Gears. Types of Gears.

Learn More

Elementary Information on Gears

Types of gears. Spur gear. Spur rack. Internal gear. Helical gear. Helical rack. Double helical gear. Straight bevel gear. Spiral bevel gear.

Learn More

PDF Gears and How Their World is Changing - The C&S CompaniesPDF

Common Gears Straight Cut Spur Gear Original, noisy Helical Smoother, but thrust loaded Herringbone Both correct for thrust problems Double Helical and rough Helical and double helical gears have multiple teeth in mesh at one time, resulting in smoother and quieter operation than spur gears. Most gears that look like this are actually double

Learn More

PDF Chapter 13 Gears—General - KSUPDF

Types of Gears • Spur gears have teeth parallel to the axis of rotation and are used to transmit motion from one shaft to another, parallel, shaft. • Helical gears have teeth inclined to the axis of rotation. Helical gears are not as noisy, because of the more gradual engagement of the teeth during meshing.

Learn More

How Gears Work - Different Types of Gears, their Functions

Depending on the type of pinion gear with which it is mated, the gear rack's teeth are either parallel (when mated with spur gears) or angled (when mated with

Learn More

GEAR TYPES & MANUFACTURING - SDP/SI

GEAR TYPES & MANUFACTURING 1. Spur Gear This is a cylindrical shaped gear in which the teeth are parallel to the axis. It has the largest applications and, also, it is the easiest to

Learn More

Types of gear box pdf - zpyc.dunnerkeil-regensburg.de

The image shows a section of a gear box with a worm gear being driven by a worm. A worm is an example of a screw, one of the six simple machines. types of gear pdf, gib and cotter joint, socket and spigot joint, classification of brakes, types of fire in hindi, application of cotter joint, different types of brakes and their applications.

Learn More

PDF Course No: M06-031 Credit: 6 PDH - CED EngineeringPDF

Gears are classified as straight, inclined and curved. 1. Straight gear teeth are those where the teeth axis is parallel to the shaft axis. 2. Inclined gear teeth are those where the teeth axis is at some angle. 3. Curve gear teeth are curved on the rim's surface. TYPE OF GEARS Here is a brief list of the common forms.

Learn More

Gears and Gear Trains

Types of Gears. 1. Parallel Shafts. Spur gears – tooth profile is parallel to the axis of rotation, transmits motion between parallel shafts.

Learn More

What is Gear Cutting? Different types of Gear Cutting Processes? [Notes

Gear cutting by Shaper process: 3.2.2 Gear cutting by Rack planing process: 3.2.3 Gear cutting in the Sunderland process: 3.2.4 Gear cutting in the Maag process: 3.3.1 Gear Hob process or Gear cutting on a Hob machine: A gear is a vital constituent of machinery.

Learn More

Types of Gearbox - Complete Explanation - Mechanical Booster

It is the oldest types of gearbox used, in sliding mesh gearbox the gears of main shaft and layshaft are not in mesh i.e. independent, only a single gear is in continuous mesh with the ge the clutch shaft that rotates the lay-shaft and the meshing of gears with the appropriate ge the layshaft occurs due to the left or right siding of the gears of the main shaft.

Learn More

PDF Introduction - University of Northern IowaPDF

Gear Types Spur gears Internal gears Most common form Used for parallel shafts Suitable for low to medium speed application Relatively high ratios can be achieved (< 7) Steel, brass, bronze, cast iron, and plastics Can also be made from sheet metal August 15, 2007 10 Gear Parameters Number of teeth Form of teeth Size of teeth

Learn More

Types of Gears: A Guide on Different Mechanical Gears

They are the commonest forms of gears that have applications in automotive, conveyor systems, gear pumps and motors, speed reducers, etc. Helical Gear Helical gears have their teeth positioned at an angle to the shaft in contrast to spur gears which are parallel. They have multiple teeth in contact during transmission.

Learn More

Types of Gear: Spur, Helical, Herring Bone, Worm Gear [Notes & PDF

Types of Gear: Spur, Helical, Herring Bone, Worm Gear [Notes & PDF] Different Types of Gear [Notes and PDF] Written by Er. Amrit Kumar in Manufacturing Technology In this article, we will be study different types of gear and those are Spur Gear, Helical Gear, Double Helical and Herring Bone Gear, Crossed Helical Gears, and Worm Gear.

Learn More

PDF Course No: M04-033 Credit: 4 PDH - CED EngineeringPDF

Types . There are four basic types of gears; spur, helical, bevel, and spiral bevel. See Figure 4. Spur gears are the most common. A spur gear has teeth that are uniformly spaced around the outer surface. The teeth are aligned in a direction that is parallel to the gear axis. A spur gear is designed to mesh with another

Learn More

Planetary Gear: Design, Parts, Function, Ratio & Uses [PDF

Three gears, a sun gear, a planet gear, and a ring gear, and many gear ratios can be obtained from a small volume as compared to other types of gear trains take up more space. Unlike simple gear trains, a planetary gear train requires defining more than one input to obtain a specific output.

Learn More

Gear Wear and Failures

Explain some types of gears and their operation. • Describe some basic gear metallurgy and what's changing in gear design. • Show how they fail.

Learn More

Gear Measurement

Most “common” type of gear, a wheel with teeth. Build the following Make sure there isn't too much friction between the gears and the beam.

Learn More