cedar rapids crushing plants

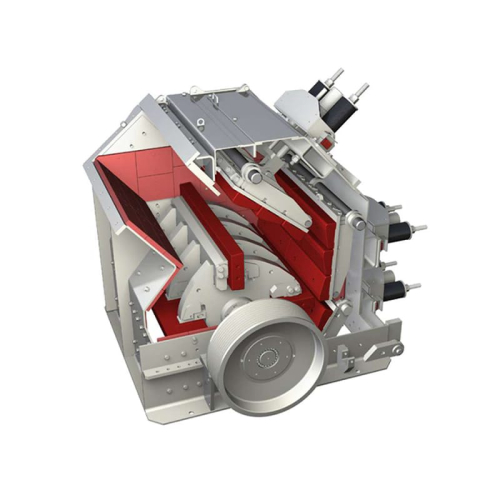

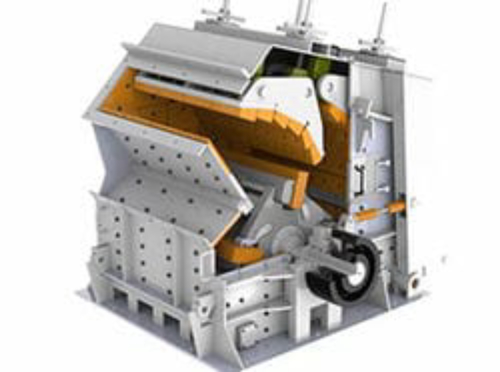

The highly mobile plant is a complete stand-alone closed-circuit unit with three product capability. The plant features a high production Cedarapids IP1313 impactor with a 3 or 4 bar 50 1270 mm rotor powered by a Tier 4, 450 hp 335 kW diesel engine, direct drive to crusher. Cedar Rapids Cone Crusher Manual Pdf. cedar rapids cone crusher manual pdf.

Learn More

Cone Crushers | McLanahan

A general rule of thumb for applying Cone Crushers is the reduction ratio. A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus,

Learn More

Cone Crusher - an overview | ScienceDirect Topics

The final product sizes are fine, medium or coarse depending on the closed set spacing, the configuration of the crushing chamber and classifier performance, which is always installed in

Learn More

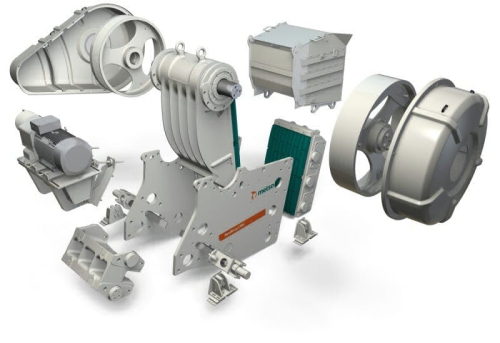

Cone Crusher Parts | Cone Crusher Spare Parts | CMS Cepcor

CMS Cepcor® is Europe's leading provider of cone crusher replacement parts, used by mining and quarrying companies worldwide. Our stock is without equal. +44 (0) 1530 540116. 7:43 pm GMT +44 (0) 1530 540116. Visit us at Bauma 2022, Munich, Germany 24th-30th October [X] Close Form

Learn More

CONE CRUSHER WEAR PARTS - Precision Casting

Cone Crusher has the features of large crushing ratio, high efficiency, low energy consumption, and uniform product size. It is suitable for medium and fine

Learn More

Spare Parts for Cone Crusher - The Nile Machinery

Spare Parts for Cone Crusher ; PSGB0607. Standard fine. 60. 6-30. 16-50 ; PSGB0609. Standard medium. 80. 10-38. 18-65.

Learn More

Crusher Parts & Consumables | MSS Limited

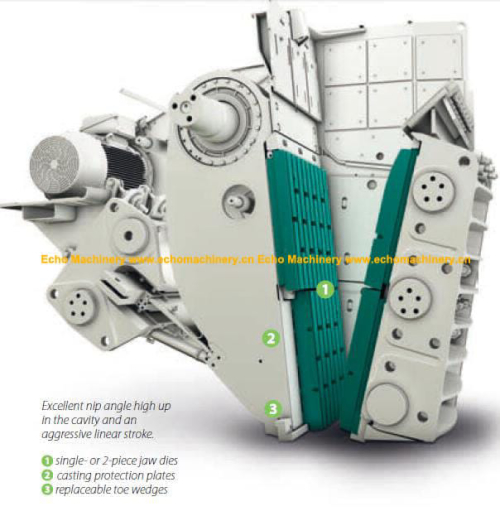

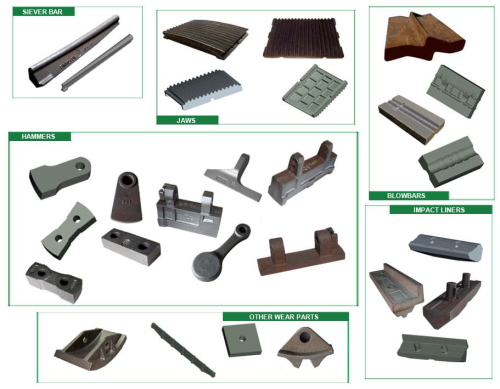

Jaw Crushers · Improved production · More accurate product sizing Project27 · Better wear mental utilization and lower discard weight · Lower overall operating

Learn More

Cone crusher and cone crusher wear spare parts

Production · Cone crusher bushing · Mantle, Bowl liner, Concanve · Cone crusher gear, pinion · Jaw crusher fixed jaw, movable jaw · Crusher mainshaft and

Learn More

Spare/replacement parts for cone crushers

Spare parts for a range of compression crushers · Arm liner · Bottom shell · Bottom shell bushing · Clamping ring · Dust collar and seal ring · Eccentric · Eccentric

Learn More

Cone Crusher - Mineral Processing & Metallurgy

4/19 · The angle of the mantle for the crushing head varies between manufacturers as does the length of the crushing zone from less than 200mm (8 inches) to more than 600mm (24 inches) but as has been indicated from the pendulum size distribution correlations it is the energy input to the feed material which determines the reduction and size distribution.

Learn More

Cone crusher basics in 4 minutes — SRP

The OSS is the largest distance between the concave and the mantle at the bottom of the crusher, so it determines the largest particle size of the outgoing product. As the smallest

Learn More

12 tips to maximize cone crusher productivity

2/11 · An example regarding the effect that crusher setting has on the product gradation is as follows, if the target crusher setting is 3/8 in. (10mm) yet the setting is not checked and it

Learn More

EXCEL™ Spare wear parts for ® Cone Crushers

Optimised EXCEL™ replacement parts cover a wide range of cone crushers and will help ensure that you get the most out of your vital crushing equipment. Our

Learn More

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

Laval Lab, the one-stop specialist in Milling. For over 35 years Laval Lab Inc is the one-stop specialist for size reduction of all types of materials. We have the right crusher, pulveriser, grinder or mill for the laboratory to pilot plant sample processing. We serve all major industries such as mining and metallurgy, chemistry, pharmaceutical

Learn More

Casteel Foundry - Cone Crusher Parts

model of crushers. ,but for the hydraulic cone crushers it also having different mantles to get more specific size and different crushing applications.

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

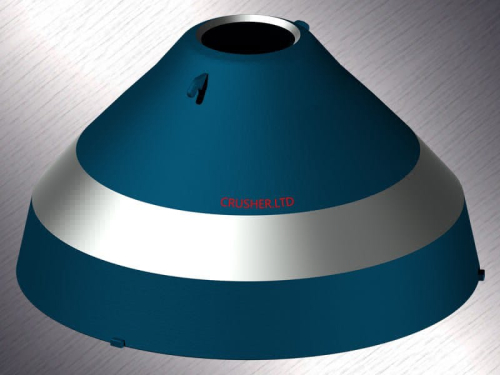

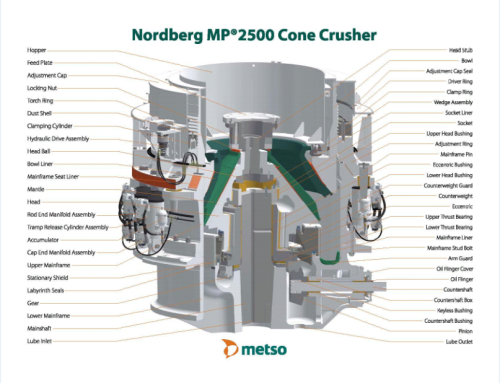

Cone crusher wear parts include cone liners, bowl liners; Cone crusher spare parts include: cone crusher spider cap, top shell, and spider, cone crusher main shaft, head center, cone crusher step bearing, cone crusher dust seal, cone crusher eccentric bushings, cone

Learn More

jeffrey hammer millsgyratory cone crusher parts specification

Brown lenox jaw crusher spare parts europe brown lenox jaw crusher spare parts europe feeding size 1525mm discharging size working capacity 0221th raw

Learn More

What is a Cone Crusher| Advantages, Types, Parts and Specifications | Quarrying & Aggregates

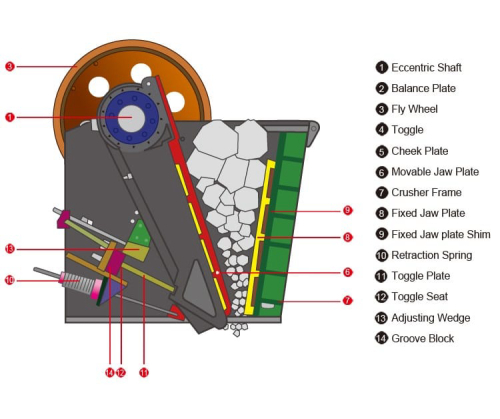

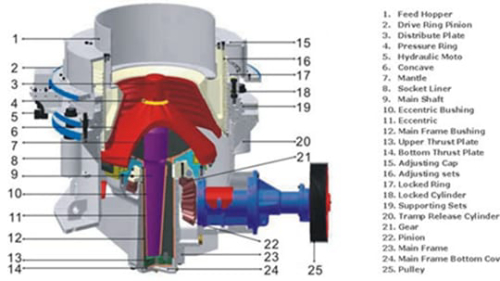

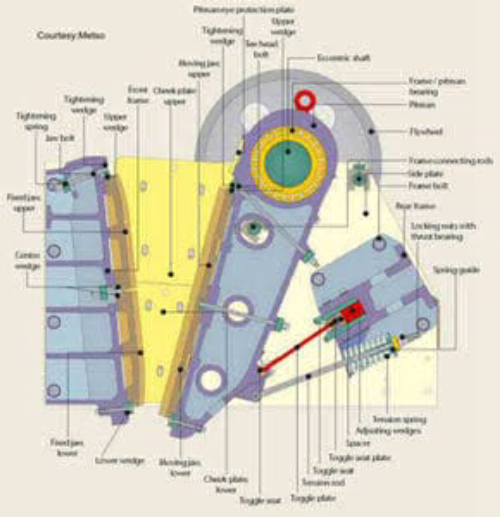

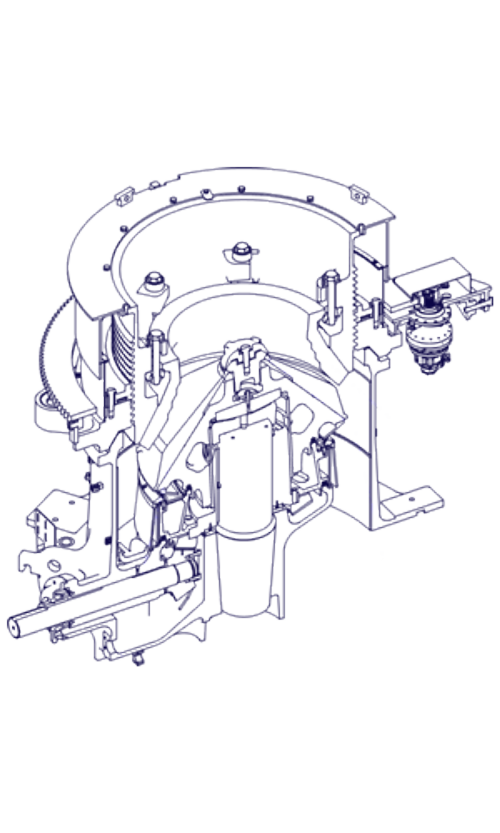

Cone Crusher Parts And Assembly The components of a cone crusher are composed of frame, drive shaft, gear, main shaft, vertebral body, cone crushing liner, shrinking cylinder, belt pulley and other devices. For more information about cone crusher liners and wear parts such as mantle liners and bowl liners, please click. How A Cone Crusher Works

Learn More

Cone Crusher Parts

Cone Crusher has the features of large crushing ratio, high efficiency, low energy consumption, and uniform product size. It is suitable for medium and fine

Learn More

cone crusher parts size | jaw cusher replacement parts

Initial Top Size: Final fineness: Description: Max. Capacity: Grinding Elements: Model: Jaw Crushers, Cone Crushers, Roll Crushers: 165 mm: 6.5 mm: Jaw crusher. MP series cone crushers Wear parts application guide. size of feed and the size of the outgoing product. It is normally measured at the 80% passing point. A typical reduction ratio in the MP standard cavity is 4-6 and in the MP short head cavity it is 3-5.

Learn More

Crusher Wear Parts Reference Guide - Corporation

Optional fit for all Jaw & Cone crushers. Work hardens quicker in abrasive applications. 14% MANGANESE. This is an option that & available if required.

Learn More

Cone Crusher Wear Parts

Cone Crusher has the features of large crushing ratio, high efficiency, low energy consumption, and uniform product size. It is suitable for medium and fine

Learn More

Cone Crusher|H Type Cone Crusher Machines available at Puzzolana

Our H type cone crushers are of advanced design with high capacity in relation to size, are used in the secondary & tertiary applications. They have high reduction efficiency and give very good product shape. Our H-Type cone crushers are available in 18 variants of capacities from 50 to 400TPH. A combination of chamber range, and high motor

Learn More

Cone Crusher Explained - saVRee

The main components of a cone crusher include the main shaft , mantle , concaves , cone , eccentric bushing , drive , crown gear , frame, and tramp release mechanism (mechanically or

Learn More

What is a Cone Crusher| Advantages, Types, Parts and

Cone Crusher Parts And Assembly The components of a cone crusher are composed of frame, drive shaft, gear, main shaft, vertebral body, cone crushing liner, shrinking cylinder, belt pulley

Learn More

Cone Crushers - Optimum Crush

CRUSHER PARTS CUSTOM MADE TO OUTPERFORM THE OEM Our team can offer custom engineered parts for your cone crusher. These are custom engineered products designed to increase life, improve strength and reduce downtime. Products include: Main Frame Liners Clamp Cylinders Clearing Cylinders Tramp Release Cylinders Feed Plates Counterweight Guards

Learn More