Gyratory Crusher Liners - Makuri Group

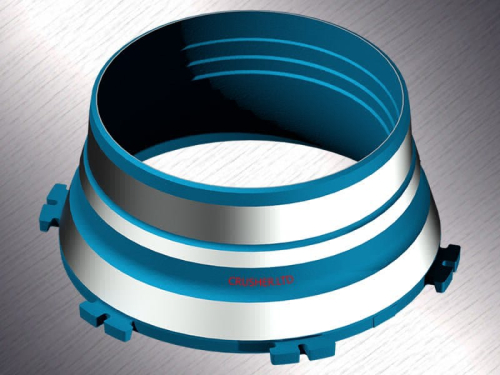

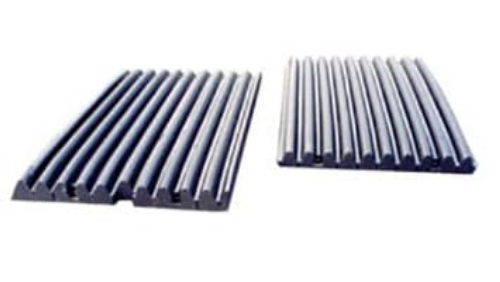

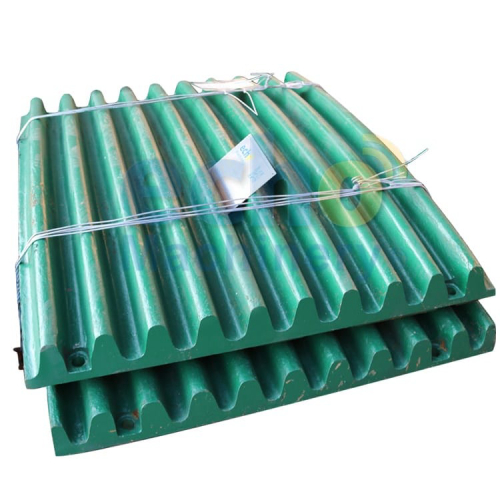

Gyratory Crusher Liners Proper design of gyratory crusher liners leads to more consistent crushed product size and predictable liner change intervals. Gyratory crushers are normally the first part of the processing plant and will often have zero redundancy. An unexpected shutdown on a gyratory crusher can reduce or eliminate crushed ore

Learn More

Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact

Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact Coal Grading Sieve Sand Making Cone Crusher Machine Parts , Find Complete Details about Gyratory Mining Gold Rock Marble Stone Aggregator Hydraulic Compact Coal Grading Sieve Sand Making Cone Crusher Machine Parts,Gyratory Stone Gold Ore Perlite Diesel Engine Tin Aggregator Pulverizer Mill Cone Crusher Mining Machine Parts

Learn More

Gyratory Crusher (KG model) | Crushing/Grinding

Gyratory Crusher (KG model)' Simple Discharge Set Adjustment. SIZE (mm), MOTOR (kW), Capacity(mt/h). Discharge Setting(O.S.S mm).

Learn More

Superior™ MKIII Series primary gyratory crushers - Outotec

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput Increased speed, installed power and mechanical improvements. Reduced downtime

Learn More

gyratory crusher | bushing grinding mills

Gyratory Crusher Lube System YouTube. systems with tank-mounted oil pumps allow oil to be circulated before crusher startup to provide pre-lubrication of the crusher internal components. gyratory crusher. Local service machinery. Local after-sales. Local demonstration. The prime gyratory crusher options take productivity a step higher.

Learn More

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

Largest jaw crusher is 1600 x 2514 mm with motor ratings of 250-300 kW. crushers (C200 series) are 1600 x 2514 mm with motors rated at 400 kW. The largest particle that can enter the opening of the jaw crusher can be estimated by: Largest particle size= 0.9 x gape

Learn More

Gyratory Crusher Sizes Manufacture and Gyratory Crusher Sizes

Gyratory Crusher Sizes - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone

Learn More

Superior™ MKIII 60-110 primary gyratory crusher

Superior™ MKIII 60-110 primary gyratory crusher is the highest capacity primary gyratory crusher that is available from Outotec's product family.

Learn More

What Type of Crusher Is Best for Primary Crushing?

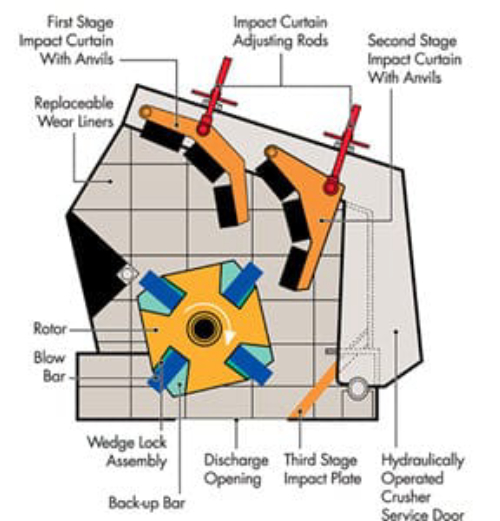

Types of Primary Crushers · Gyratory Crushers · Jaw Crushers · Hammermills · Horizontal Shaft Impact Crushers · Sizers · Roll Crushers · Cone Crushers

Learn More

Gyratory VS Jaw Crushers: Advantages & Disadvantages

Feb 28, · Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation. The jaw crusher is more easily adjusted, to compensate for wear of liners.

Learn More

Modelling the crushing-sizing procedure of industrial gyratory

For the development of the models, typical product size-distributions of gyratory crushers were used. Various curves from two sources referred

Learn More

Gyratory Crusher Feed Size - This Week in Fedora

Gyratory crusher, 60 x 89 , manufactured by Allis Chalmers. 48 maximum feed size. Includes straight bottom shell design, lower top shell, top shell section, spider, Industrial Solutions Gyratory crushers They depend on the feed characteristics and the crusher configuration.

Learn More

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

Throughput 2,000 t/h Product P80 ≤ 150 mm Feed size in block caving max. 2,000 x 1,500 x 1,000 mm Right: Moving a semi-mobile crushing plant with KB 63-114 gyratory crusher for overburden and copper ore. Throughput > 10,000 t/h Our services keep things running smoothly! One-stop- shop service

Learn More

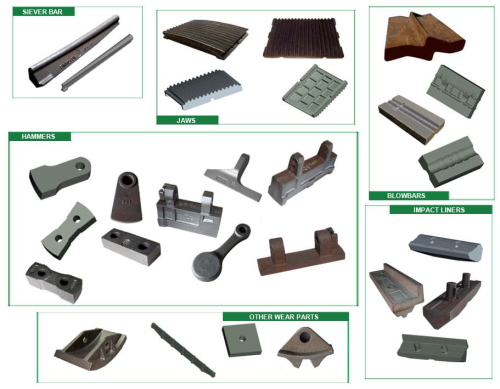

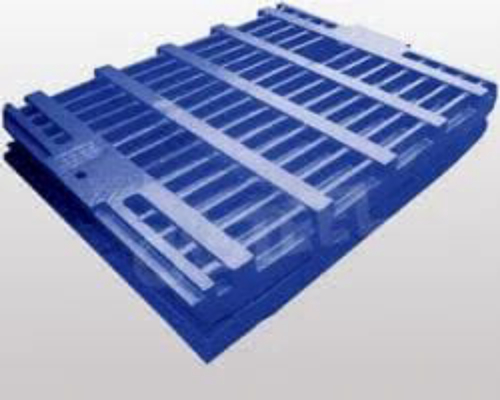

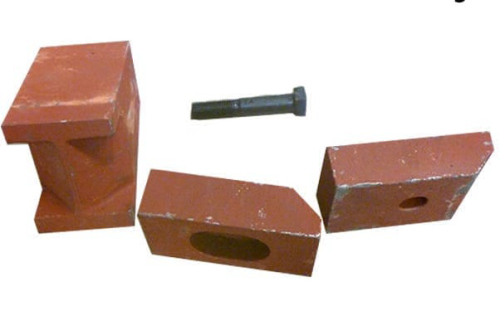

Compression mining crushers | Primary crushers

Incorporate our engineering expertise into any and all of your crushing systems, no matter the size, up to and including systems for total plant. We can provide you with compression crusher parts as well as complete compression crusher machine units, such as gyratory crushers, jaw crushers and cone crushers.

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining

Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h Cyclo-palloid spiral bevel gear Higher-capacity drive motors if required Rugged design Direct feed possible High throughput rate

Learn More

Gyratory and Cone Crusher - ScienceDirect

The rule of thumb for descri the dimensions of primary gyratory crushers may be summarised as 1. for sizes < 66 cm, the circumference along the opening = 8-10 × gape (measured along the outer perimeter), 2. for sizes > 66 cm, the circumference along the opening = 6.5-7.5 × gape (measured along the outer perimeter), 3.

Learn More

Superior™ MKIII 50-65 primary gyratory crusher - Outotec

Bring new levels of increased throughput and lower downtime to your process. Superior™ MKIII 50-65 primary gyratory crusher is a great overall addition to your mineral processing circuit. Giving the same results as a larger crusher, Superior™ MKIII 50-65 brings efficiency with higher throughput and lower downtime in primary crushing.

Learn More

CG810 Primary Gyratory Crusher For Maximum

It can also automatically adjust your crusher settings to compensate for crush-ing chamber wear – ensuring consistent product size. The Tank Instrument

Learn More

How do you size a gyratory crusher?

Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle

Learn More

Gyratory Crusher. 시장 2022 최신 개발, 동향 및 수요, 크기, 공유, 성장, 동향 및 예측, 2028

글로벌 Gyratory Crusher. 시장 2022-2028 보고서는 수익, 거래량, 규모, 가치 및 이러한 귀중한 데이터를 다룹니다. Gyratory Crusher. 시장 보고서는 수많은 다른 시장 관련 기본 요소를 포함하는 체계적인 시장 조사 보고서를 통해 Gyratory Crusher. 시장의 기회에 대한

Learn More

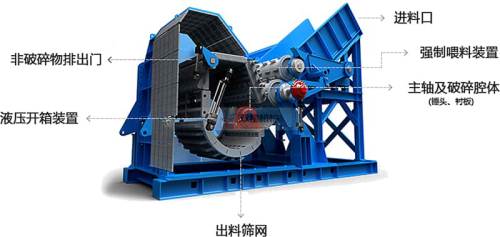

Gyratory Crusher-MECRU

The gyratory crusher has a huge output and is often used for coarse crushing operations of large enterprises or large production lines. It can crush the raw material ore produced by drilling and blasting to a suitable particle size for subsequent crushing process or beneficiation process. It is the key to the entire process.

Learn More

GYRATORY-CRUSHERS.pdf - RocketCDN

Early mines were small, using shrinkage stoping and small mine can. The capacity of material handling was small, limiting the size of the largest piece and the

Learn More

Crushing equipment - UZTM-KARTEX

The crushers are designed for reliable operation in different climatic conditions Max. lump size of feed, mm Primary and reduction gyratory crushers.

Learn More

2. GYRATORY CRUSHERS - Metallurgist & Mineral

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units

Learn More

Crusher - Wikipedia

Ruffner Red Ore Mine gyratory crusher Gyratory crushers are designated in size either by the gape and mantle diameter or by the

Learn More

PDF 2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing EngineerPDF

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn More