PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1. Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1. The primary operating variable available on a crusher is the set and on jaw and gyratory the open-side set (OSS) is specified. This reflects the fact that considerable

Learn More

en/reduction ratio crusher.md at main · /en - GitHub

19 Nov 2009.The reduction ratio for jaw crushers range from 3 1 to 5 1.Jaw crushers range in sizes from 12 inches (30 cm) to 1.5 inch (38 mm).Jaw crushers can

Learn More

Rock Crusher with a High Reduction Ratio - RUBBLE MASTER

Exceptional Reduction Ratio Up to 30% Fines after 1 Pass Lowest Operating Costs The RM V550GO! can replace a traditional jaw cone, and screening plant setup. Like all RUBBLE MASTER impactors it features all the benefits that make it easy and safe to operate. One-Man Operation Your loader operator controls the crusher conveniently from his cab.

Learn More

Ball Mill Reduction Ratio Industry | Crusher Mills, Cone Crusher, Jaw

Size Reduction Equipment | Paul O. Abbé - New Drying, Mixing . Paul O Abbé Equipment Company is a manufacturer of new Size Reduction Equipment such as Ball Mills, Jar Mills, Slice Mills and more. Call 800-524-2188 or request a .

Learn More

Basics Of Jaw Crushers - IMS Engineering

A jaw's reduction ratio is approximately four to one, and a jaw crusher is commonly used as a primary crusher for initial size reduction or to

Learn More

Reduction Ratio Range For Jaw Crusher

Reduction Ratio Of Jaw Crusher . 5 x 7 high reduction ratio jaw crusher. 2020-5-20the 911mpe-tm-t is a jaw crushers for coarse primary crushing and mid range primary crushing this jaw crusher is equipped with a 5 hp motor and a 5 x 7 jaw cavity that will produce a discharge crushed product of under 1mm well proven single tog.

Learn More

Reduction Ratio In Jaw Crusher-HN Mining Machinery Manufacturer

Setting jaw crushers. Ideally, the reduction ratio of a jaw crusher should be 6-to-1. There are different ways to calculate reduction ratio, but the best way is something called the P80 factor. Mar 16, Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio.

Learn More

Reduction Ratio Calculation Jaw Crusher Stone Crusher Equatorial Guinea?

59 x 59 primary impact crushers are preferred for their high performance and high reduction ratios in crushing softcharacter substances like gypsum and limestone due to the different principle of crushing these materials the reduction ratio is higher than in jaw crushers dimensions ro.

Learn More

Crusher Reduction Ratio - Mineral Processing & Metallurgy

For a given ratio-of-reduction, the type of crusher with a flared crushing chamber will usually deliver a cleaner product than any of the older types; conversely, more reduction can be performed in the machine without creating excessive fines. The facts outlined in the foregoing paragraph have an important bearing on crushing plant design.

Learn More

How to Calculate and Solve for Crusher Reduction Ratio | Mineral

Oct 05, · The formula for calculating crusher reduction ratio: R r = G / S. Where: R r = Crusher Reduction Ratio G = Gape Size S = Set Size. Let’s solve an example; Find the crusher

Learn More

REDUCTION RATIO FOR BALL MILLING | Crusher Mills, Cone Crusher, Jaw

Let's look at my ball mill for example of how reduction ratios. It is important to understand this so that you can figure out what size pulleys you will need. Archive of SID The average values of reduction ratios for rod and ball mills were equal to 64.65 and 1.15, with standard deviation of 3.91 and 0.03, respectively.

Learn More

impact crusher reduction ratio asphalt

BORATAŞ MAKİNA primary impact crushers are high yield capacity crushers High reduction ratio Very good cubical shape in asphalt and concrete product . in Concrete for CiteSeer Quarries producing crushed stone and hot mix asphalt for road construction PEW series Jaw crusher features big crushing ratio stone crusher PPT .

Learn More

Tips for maintaining efficiency in crushing circuits - Quarry

Ideally, the reduction ratio of a jaw crusher should be 6:1. There are different ways to calculate reduction ratio, but the best way is

Learn More

Introduction to Rock Crushers

Jaw crushers normally take the mined material and reduce it to a manageable size -say 10 to 4 inches. Cone crushers take the material from a jaw crusher and further reduce the material size. Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio.

Learn More

What Is the Reduction Ratio of the Crusher?

Surface reduction ratio:the ratio of the width of the crusher inlet to the width of the outlet Calculation formula: I=0.85B/S (inlet width/discharge width referred to here) 0.85 is the

Learn More

When to Choose a Jaw Crusher VS Cone Crusher VS Impact

Jaw crushers are typically used in a scenario that requires a reduction ratio of 10:1. A jaw crusher 30” opening has a 3-inch minimum closed side setting.

Learn More

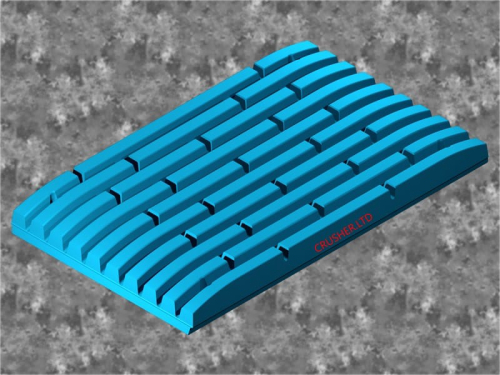

size reduction jaw crushers size reduction mill

Jaw Crusher Explained . For example a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw when measured at the top the opening and each jaw will have a 54 inch width If a jaw crusher is rated by jaw plate size a suitable rating maybe 600 x 400 which indicates a 600 mm by 400 mm jaw . احصل على السعر

Learn More

Reduction ratio of Cone crusher,impact breaker,roll crusher,Jaw

Dec 31, · Reduction ratio is 20 to 1. Reduction ratio of Jaw crusher A crusher that breaks material by squeezing or compressing it between two jaw plates, one moveable and one

Learn More

Introduction to Rock Crushers - ELRUS Aggregate Systems

Jaw crushers offer reduction ratios of up to about 6:1, while cone crushers can reduce material size up to a maximum of 8:1 ratio. The finer the crushing, the smaller the reduction ratio.

Learn More

Choke Feed Level and Effective Reduction Ration

Instead of the one-stage reduction, the capacity of the jaw crusher with a three-stage reduction has been an increase of between 38% and 82% according to coal

Learn More

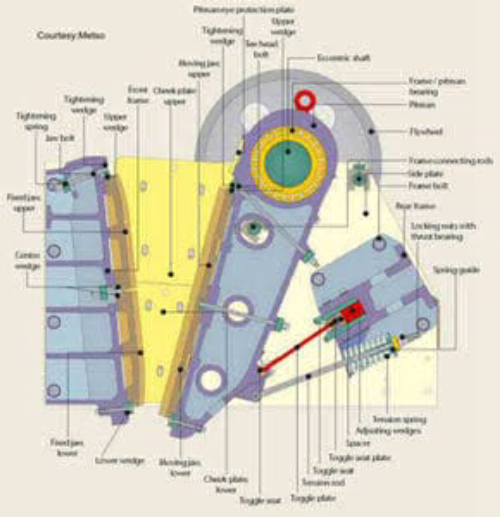

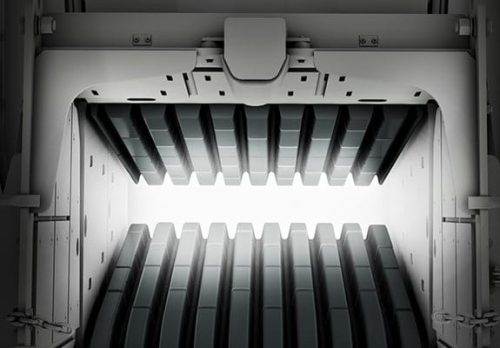

What is a Jaw Crusher? - MEKA Crushing Equipment

MEKA Size Reduction Machines WHAT IS A JAW CRUSHER? / JAW CRUSHER. Size reduction ratio. The ratio of the gape width to the near side jaw opening. This ratio may vary from 1/3 to 1/9, but is generally 1/3 for primary crushers and 1/4 for secondary crushers. θ: Nip angle.

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

For a jaw crusher the thickness of the largest particle should not normally exceed 80–85% of the gape. Assuming in this case the largest particle to be crushed

Learn More

Crushing 101 » Masaba Manufacturing

8:1 maximum reduction ratio for compression crushing, this is normally used as a primary crusher. Jaws perform well in many materials.

Learn More

reduction ratio in stone crusher crusher machine in raipur

The secondary and primary crushing procedures utilize these crushers quite frequently When you are crushing abrasive materials in tough blocks you must use the

Learn More

reduction ratio crushing in

5″ x 7″ High Reduction Ratio Jaw Crusher. The 911MPE-TM-T is a Jaw Crushers for Coarse Primary Crushing and Mid Range Primary Crushing. This jaw crusher is equipped with a 5 HP motor and a 5 ” X 7″ jaw cavity that will produce a discharge crushed product of under . 1mm. Well proven single toggle, high reduction Jaw Crushers

Learn More

How To Calculate Reduction Ratio Of Jaw Crusher

Crusher setting when the discharge opening of the jaw crusher is at closest position Divide the top size by the CSS to obtain the reduction ratio (eg 6” top size/1” CSS = 6:1 ratio) The measure of the ability of a liquid or solid to resist flow Get PriceCalculate the Reduction Ratio and the Number of Milling ,28/03/ Before going to the

Learn More