Difference between Cone & Gyratory Crusher

28/01/ · A gyratory crusher has a higher angle at the cone apex. This provides a longer residence time along the crushing interface and is supposed to generate a smaller & more consistent product. Minerals have much more, probably much better, information on their website. 28th January , 0:44 #3.

Learn More

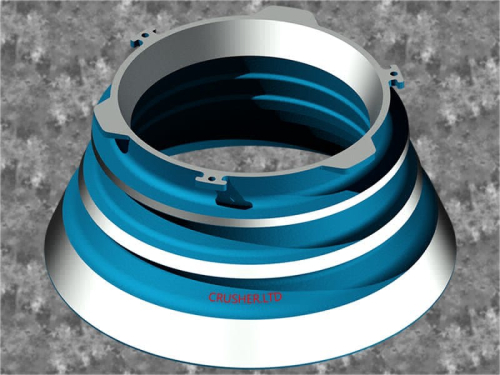

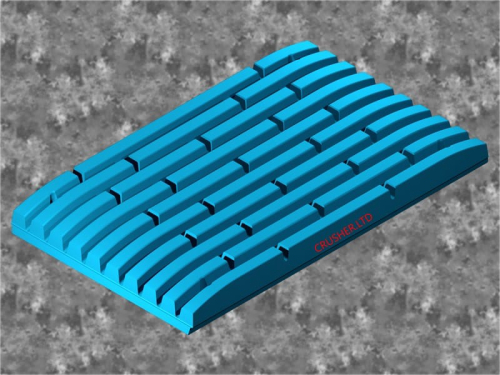

Gyratory Crusher Liners

We offer Gyratory Crusher Liners tailored to your needs and manufactured for increased productivity. Here is what sets our Gyratory Crusher Liners apart: (1) Gyratory Crusher Liner design is selected based on customers' application (2) We use high quality materials and a robust Quality Control Program for all liners

Learn More

2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing

CRUSHING 2. GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product

Learn More

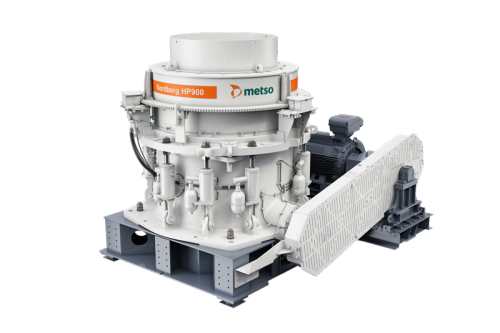

Superior™ MKIII Series primary gyratory crushers

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers

Learn More

Gyratory crusher | Hub-4

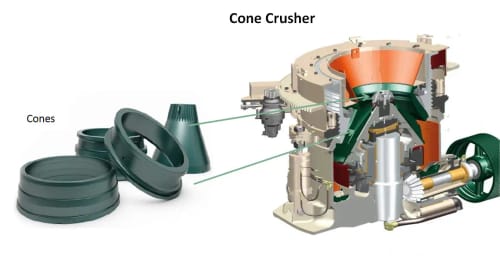

A gyratory crusher is used to crush rock between a mounted crusher cone and a fixed crushing chamber. Often used to perform a secondary,

Learn More

Gyratory crushers - Hardox Wearparts

A gyratory crusher is a mining or ore processing machine that crushes feed material between an eccentrically mounted cone and a fixed crushing throat.

Learn More

PDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

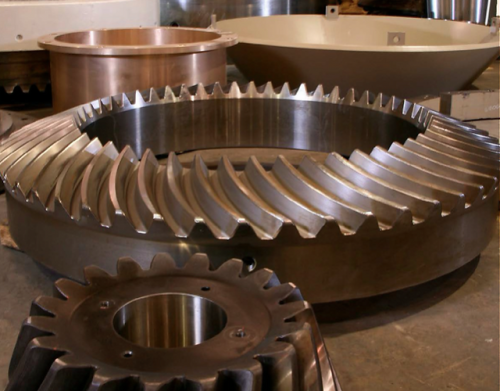

Jaw gyratory crushers - design and operating principle Technical data The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, to- gether with the upper part of the mantle, it forms the initial crushing zone. The

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Learn More

Gyratory Crushers - Sandrock Mining

Gyratory Crushers. Sandrock Mining Gyratory crushers are frequently used in the primary crushing stage and a little less often in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the

Learn More

CG830 Gyratory crusher — SRP - rockprocessing

CG830i crusher offer excellent reliability and safer & faster maintenance – up to 30% faster than competing crushers. A robustly designed one-piece main

Learn More

construction of gyratory crusher

15/09/2022 · WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn More

Gyratory Crusher

HGT Hydraulic Gyratory Crusher is a primary crusher integrated mechanical, hydraulic, electrical, automated and intelligent control together. And the automatic control system is the greatest feature, makes operation more convenient. PERFORMANCE why choose our Gyratory crusher: Efficient and Intelligent Production.

Learn More

Gyratory Crusher How It Works

Gyrating crusher broken cone of the cyclic movement of the cone cavity within the shell, squeeze the material, splitting and bending, rough chopped . What Is The Working Principle of Gyratory Crusher? - Crusher FAQ. When it comes to Replacement Gyratory Crusher Parts, Excel has been crushing the market for decades.

Learn More

Gyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher: Introduction The design of the gyratory crushers and jaw type gyratory crushers is based on more than one hundred years of experience of . US Patent # 5,718,390. Gyratory crusher – Patents.com. A gyratory crusher includes a flexible dust seal having an outer edge attached to a cone head of the crusher and to an outer of a

Learn More

What Type of Crusher Is Best for Primary Crushing?

Gyratory Crushers are an excellent choice for a primary crusher, as they can handle very hard and abrasive material. They are ideal for dry

Learn More

Gyratory Crushers of the Sierra Pinacate, Sonora

The gyratory crusher resembles a perforated mortar, either in slab or block form, in which a wooden pestle with a projection extending through the perforation

Learn More

How A Gyratory Crusher Works

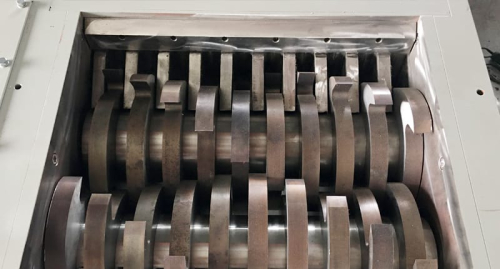

Crusher & Grinder « Novamining. What is a Cone Crusher and how it works? The cone crusher is a modified version of gyratory crusher. The essential difference is that the shorter spindle of the cone

Learn More

Gyratory Crusher Operation - Mineral Processing & Metallurgy

18/07/ · Gyratory Crusher Operation. Crusher are used to reduce the ore in size, the purpose and the responsibility of the crusher operator is to operate that crusher in such a manner as to

Learn More

Gyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn More

Operating Principle Of Gyratory Crusher

Gyratory crusher also named cone crusher is a large crushing machinery,The A gyratory crusher comprising:a bowl Primary Gyratory Crushers size,principle,operation in South The Mining Machine is custom designed to reduce your operating costs and increase your mine production by getting your mining, haulage and conveying systems to be

Learn More

what is gyratory crusher gape

The Gyratory crushers are similar to cone crushers but they are three times greater than that of a jaw crusher of a similar gape; the gyratory has a Comparision between the crushers - Ranjit Gape length:- It is the width of the receiving opening of the crusher.

Learn More

Jaw Crusher VS Gyratory Crusher - JXSCMACHINE

The gyratory crusher is taller than the jaw crusher, thus needs a high workshop design. Besides, gyratory crusher is heavy than jaw crusher, it's not convenient to move. Capacity. Gyratory crusher can work continuously, has high productivity and crushing ratio ( up to 6-9.5), working performance is very stable, light vibration.

Learn More

What Are the Differences Between The 7 Types of Crushers?

Jaw rock crusher VS gyratory crusher Different crushing principles Jaw crusher is a compression type of crushing machine. The flywheel works together with eccentric shaft and toggle plate provides a motion which pushing moveable jaw plate towards stationary jaw dies, and during the process, a compressive force squeezes raw material.

Learn More

Gyratory Crusher Services I Service - thyssenkrupp Mining

Gyratory Crusher Services Patrik Handel 2022-04-27T13:06:08+02:00 thyssenkrupp Gyratory Crusher Services for optimized Operation & Maintenance Get the best out of your gyratory crushers – with services from thyssenkrupp which combine decades of expertise with state-of-the-art technology.

Learn More

Gyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn More

Crusher Close Side Settings - Mineral Processing & Metallurgy

17/01/ · Crushing angles may vary between the approximate limits of 22 and 30 degrees in a line of standard gyratory crushers. It is possible to use larger angles in the larger sizes of crushers because the greater weight of the individual pieces of material tends to minimize slipping. In these large machines, a difference of a few degrees in the

Learn More