10 Best Pill Crushers September 2022 - MSN

9. 4 Pack Pill Crusher Pulverizer Grinder with Storage Container, 2 x 3.25 inch. By juvale. 7.4. View Product. 7.4. 10. Medline Silent Knight Pill Crusher Pouches (Pack of 1000) By biotene.

Learn More

Types of Crushers: What You Need to Know - Machinery Partner

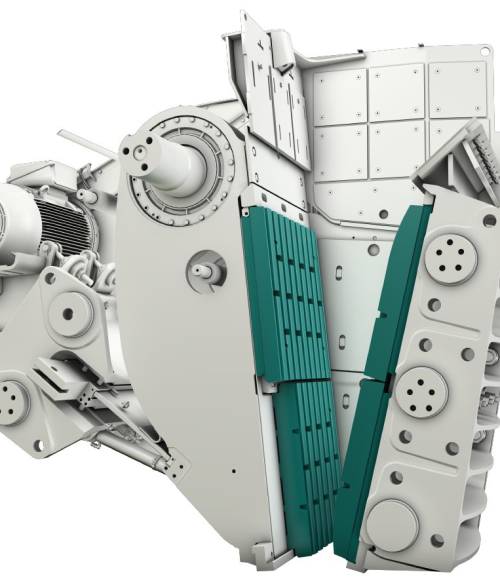

Primary crushing produces materials ranging from 1500mm to 350mm, on average. The two main types of primary crushers are: Jaw Crushers: large amounts of material are fed into the “V

Learn More

Buyer's Guide: Crushers - Equipment & Contracting

Jaw Crusher. A jaw crusher is the most commonly used primary crusher. · Impact Crushers. An impact crusher (also called a hammer crusher) is quite versatile.

Learn More

So How Exactly Does a Rock Crusher Work? - Geology

9/22 · A rock crusher is a device used to crush rocks into smaller pieces, usually for gravel or some other road or building application. Most rock crushers have a hopper at the top — a container which holds the rock above the crusher and uses gravity to feed it in. Alternately, rock crushers can use a belt drive to .

Learn More

Crusher - DND 5th Edition - Wikidot

Crusher. You are practiced in the art of crushing your enemies, granting you the following benefits: Increase your Strength or Constitution by 1, to a maximum of 20. Once per turn, when you hit a creature with an attack that deals bludgeoning damage, you can move it 5 feet to an unoccupied space, provided the target is no more than one size

Learn More

Jaw Crusher Explained - saVRee

Purpose of Crushers. A crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste ( gangue) material.

Learn More

All crusher types for your reduction needs - Outotec

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher.

Learn More

Jaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn More

Crusher drone by MarModels - Thingiverse

Download files and build them with your 3D printer, laser cutter, or CNC. Thingiverse is a universe of things.

Learn More

What is a Rock Crusher transmission? - Quora

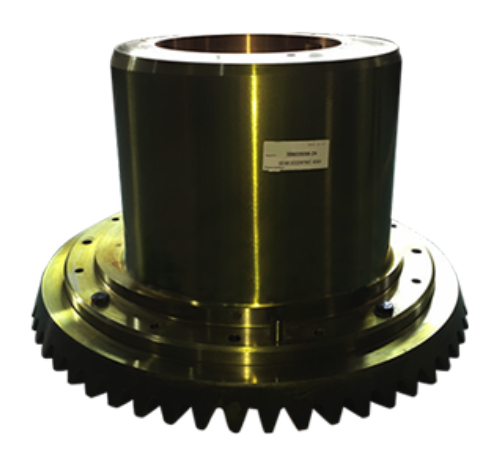

Answer: It's a GM Muncie M22 four speed, used in high performance applications from 1965 to 1972. They had a lower helix angle in the gears and had a noticeable whine that very few other transmissions had. If you were running a GM hotrod, that was the manual

Learn More

What Is a Cone Crusher and What Can It Do for You?

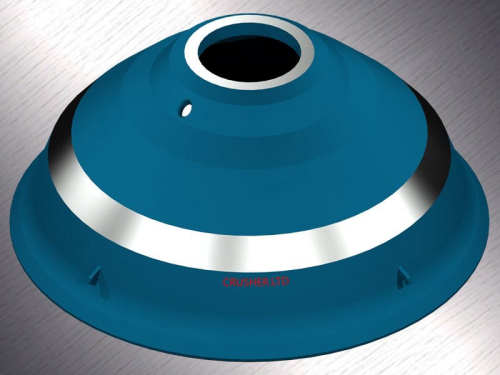

Apr 24, A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like aggregates and construction and demolition waste. The cone crusher distinguishes itself from these other crushers by how it operates in processing material.

Learn More

Crushers - QueensMineDesignWiki

Crushers play an important role in the material handling process for underground mine operations. The main purpose of a crusher is the size

Learn More

7 Different Crushed Stone Sizes and Their Applications - ReAgg

Generally, as the grade number goes up, the size of the stone goes down. #1 - The # 1 crushed stone grade is the largest of the crushed stone grades and includes stone between 2-4 inches long. This material is great for larger jobs or for filling in larger holes. #3 - This size of the stone ranges from 1/2 to 2 inches long.

Learn More

Crusher definition and meaning | Collins English Dictionary

A crusher is a machine which breaks up solids by pressing them. A rock crusher is a machine designed to take large rocks and reduce them to smaller rocks,

Learn More

How it Works: Crushers, Grinding Mills and Pulverizers

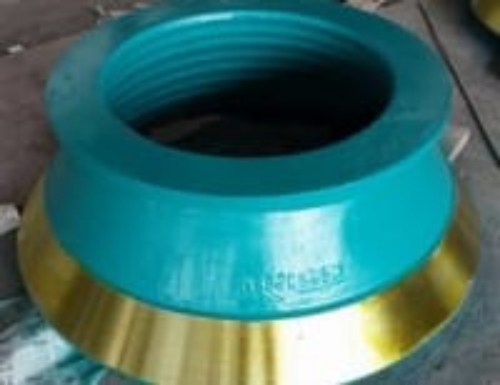

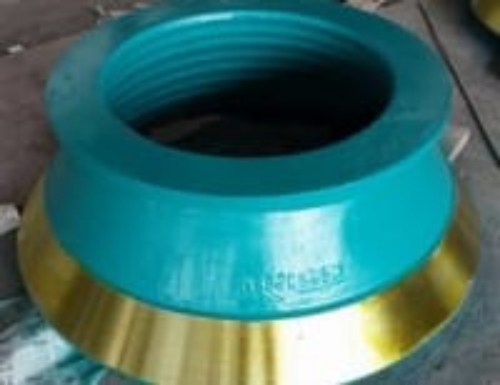

Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap between the bowl liner and the mantle narrows, the rock is

Learn More

Types of Crushing Equipment - Jaw, Cone & Impact

A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain

Learn More

Clearing Blocked Crushers - Health and Safety Authority

Jaw crushers operate by squeezing rock between two surfaces, one of which opens and closes like a jaw. Rock enters the jaw crusher from the top. Pieces of rock,

Learn More

Cone Crushers | McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point. As the wedge or eccentric rotates to cause the compression within the chamber, the

Learn More

What Type of Crusher Is Best for Primary Crushing?

Types of Primary Crushers · Gyratory Crushers · Jaw Crushers · Hammermills · Horizontal Shaft Impact Crushers · Sizers · Roll Crushers · Cone Crushers

Learn More

Crush Definition & Meaning

OTHER WORDS FROM crush ; crush·a·ble, adjective ; crush·a·bil·i·ty, noun ; crush·a·bly, adverb ; crusher, noun.

Learn More

Stone crusher Definition & Meaning - Merriam-Webster

The meaning of STONE CRUSHER is a machine for crushing stone.

Learn More

Everything You Need to Know About Rock Crushers

Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap

Learn More

What does Crusher mean?

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form,

Learn More

Crusher, Crushing plant - All industrial manufacturers

A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks of a maximum size.

Learn More

Cone Crusher Parts - Mineral Processing & Metallurgy

2/19 · Cone Crusher MAINSHAFT. The mainshaft is of high grade forged steel, annealed for stress relief. It is tapered to gauge for head center fit. The bottom of the shaft is fitted with a polished bronze step bearing. The journal for the spider bearing is formed by a sleeve shrunk on the shaft on the 51, 60 and 84-in. crushers.

Learn More

What Is a Jaw Crusher and What Can It Do for You?

11/8 · A jaw crusher is one of several types of crushers, including impactors, hammermills, and cone crushers, that are manufactured for the purpose of processing aggregate minerals, RAP, and recycled concrete with rebar, to name a few applications. There are two types of crushing, compression or impact. Jaw crushers and cone crushers use a compression force

Learn More