The pros and cons of cone crusher applications - Quarry

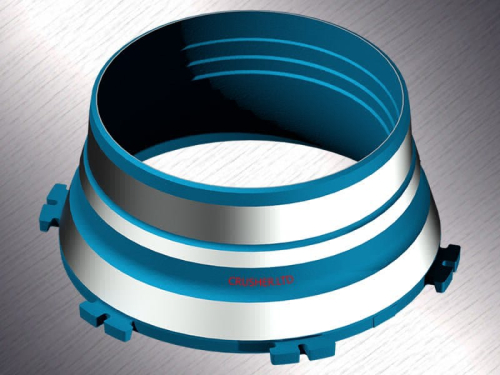

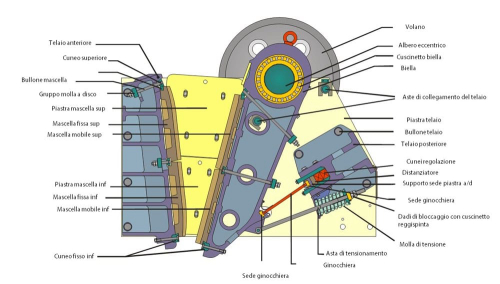

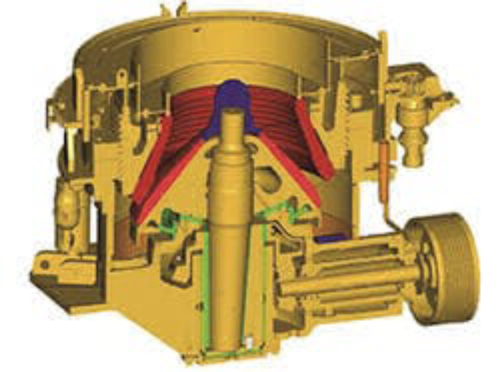

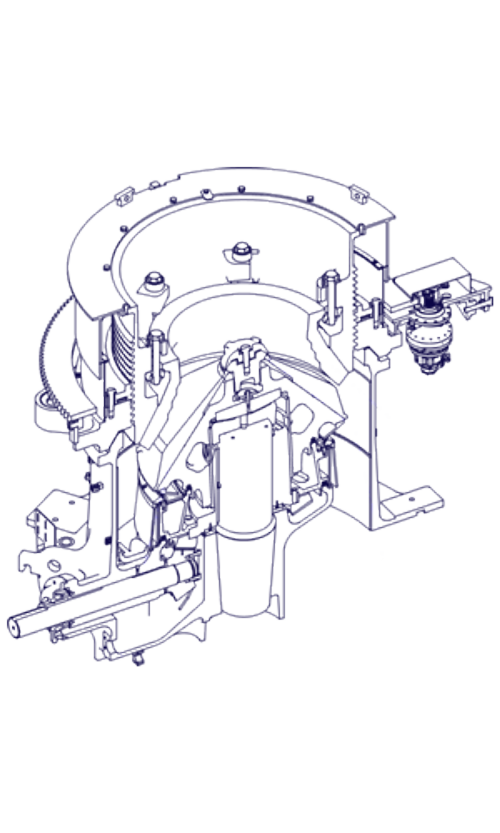

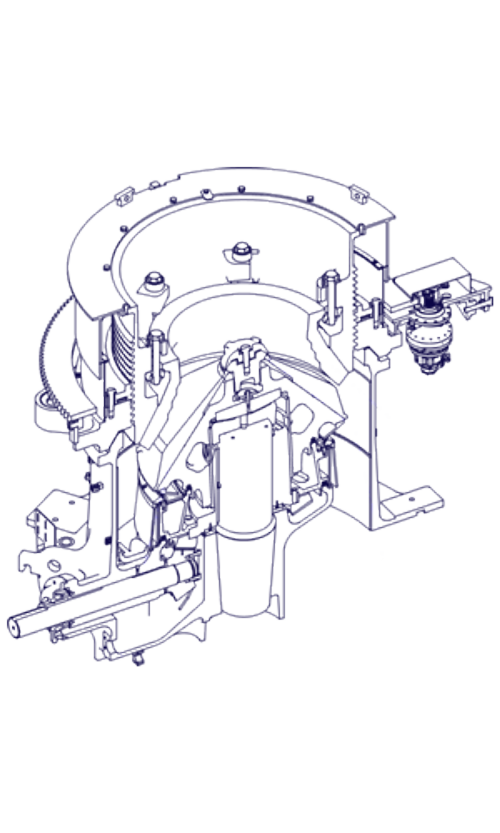

The mechanical factors that affect the production rate and quality of the material processed by a cone crusher include: Cone head diameter. Crushing chamber slope (angle). Cone head stroke. Gyrating speed. Manganese liner profile. Closed side setting (CSS). Crushing force, monitored as operating pressure. Applied power. Feed control.

Learn More

Resolving high wear in cone crushers - Columbia Steel

This is the most common phenomena present in cone liners and the subject we deal with most often when providing our Hi-Pro / H-D liner profiles to customers

Learn More

cone crusher liner profiles | woolen mills spare shaft sleeve tools

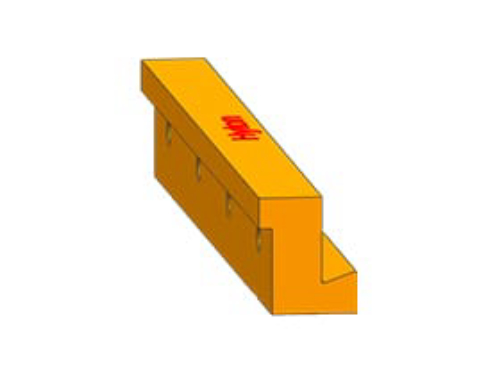

Western Areas that development of a custom liner profile for their TC51 cone crusher liners would provide significant benefits. HEPICS improved the profile by changing the crusher cavity shape to ensure utilisation of the remaining life of the mantle occurred. The profile change in stage two extended the liner life from 39 days

Learn More

What is the wear profile of your crusher trying to tell you

After this webinar, you will: Be comfortable identifying and diagnosing liner related issues seen on most high-speed cone crushers, gyratory crushers, and jaw

Learn More

cone crusher liner profiles | electrical copper-alloy casting jaw crusher

In a cone crusher, Continuous Improvements on customers TC51 Cone Crusher. H-E Parts improved the cone crusher's liner life by upgrading the of a custom liner profile for their TC51 cone crusher liners would Superior P300 Patriot® Cone Crusher. Superior P300 Patriot® Cone Crusher. Standard Features. Weight-Approx. 33,500 lbs, bare

Learn More

Wear in cone crusher chambers | Request PDF - ResearchGate

The crushing process is governed by the geometry of the crusher liners. Previous research has made it possible to model the crushing process for

Learn More

cone crusher liner profiles | oem cone crusher bottom shell

cone crusher liner profiles | high manganese concave cone crusher bottom shell bushing mp1000 expansion cable 1769-crl1 pelletizing machine cone crusher rubber roller bearing 1769-crr3. hp crusher part china supplier spare eccentric inner bush for mine ore mining crusher cone crusher manual pdf.

Learn More

cone crusher liner profiles | crusher spare gear including

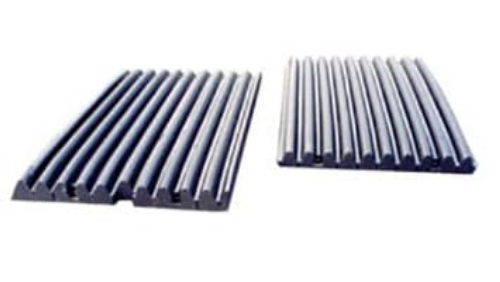

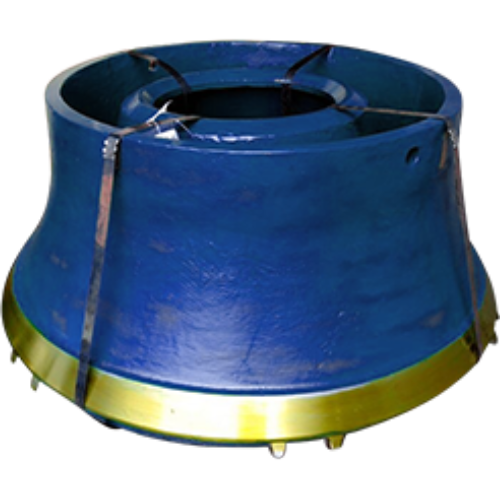

Mantle Bowl Liner Concave, Cone Crusher Wear Parts. Mantle, Bowl Liner and Concave are the main wear part of Cone Crusher. We provide the matching products according to the customers' machine type. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on. Our cone parts are widely used on mining

Learn More

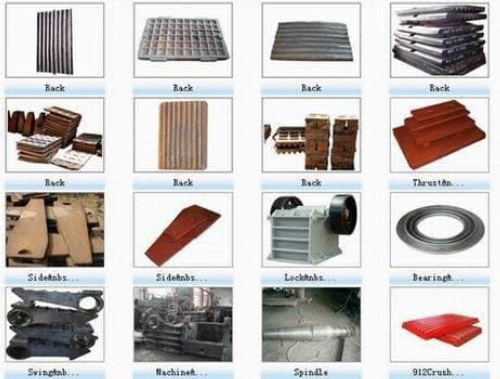

Crusher Wear Parts Reference Guide - Corporation

Cone Crusher Wear Parts. 4. Impactor Crusher Wear Parts. Topics within these sections include metallurgy options , liner profiles available , application

Learn More

cone crusher liner profiles | nordtrack

the crushing stages Constant liner profile Maintains the feed opening and performance during the entire service life of the liners Two standard crushing chambers are available for the CS550 and the crusher can easily be matched to changes in production by selecting the right chamber and eccentric throw.

Learn More

Manganese Crusher Liners - Mining Wear Parts

Our aftermarket Manganese crusher liners for cone, jaw, gyratory, sooner to achieve the benefits of the liner and to maintain the liners new profile.

Learn More

HP series cone crushers - Frantoparts

liner as measured when they are at their Wear parts application guide - HP series cone crusher Check the wear profile of the liners: a.

Learn More

Jaw Crusher Liners - Tempus Steel

Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by generating more accurate

Learn More

cone crusher liner profiles | giga crusher bottom shell bushing

Cone crusher liner profile gauges have gained significant interest among quarrying producers in recent years. Using Your Blackhawk Cone Crusher For Mining Operations. 27/2/ · The cone crusher is best suited for medium or small sized operations that require a powerful, compact design. They work on a variety of mineral recovery plants.

Learn More

Cone Crushers | McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1

Learn More

PDF Application guide ® MP Series™ cone crusher wear parts - MetsoPDF

Check the crusher operating speed Make sure that the operating speed of the crusher matches the application and liner profile used. 3. Check the cavity in use • Based on feed size • Based on the required end product size which determines the required setting range • Check the crushing reduction ratio 4.

Learn More

liners for cone crushers | upper thrust bearing of mobile stone crusher

Cone Crushers are the earliest cone crusher in the world with over 50 years. 4829-7591, 3 ft, short head, 3′ SH bowl liner, 824. jaw crusher wear socket liner for sale india spare brass parts vertikal crusher v vibro king screen part Z276 VIBRATING MOTOR 3.35KW-460V-60HZ-1728RP screen manual

Learn More

cone crusher liner profiles | wear and spare parts for stone crushers

Jaw Crusher Liners. Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by generating more accurate The pros and cons of cone crusher applications. 16/4/ · A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio.

Learn More

cone crusher liner profiles | rock crusher 250x400 ans spare copper

Bowl Liner and Mantle Wear Analysis are reviewed and profile China Cone Crusher Liner Factory and Manufacturers. Cone Crusher Liner Manufacturers, Factory, Suppliers From China, Your inquiry might be extremely welcomed plus a win-win prosperous development are what we've been expecting. Hardening by Transformation and Cold Working in a

Learn More

Application guide ® MP Series™ cone crusher wear

The MP Series™ cone crusher is a compressive crusher that crushes feed material between a fixed bowl liner and a movable mantle. Bigger rock particles are crushed directly between the surfaces of the mantle and bowl liner. This is called single-layer crushing.

Learn More

Cone crusher parts - Outotec

The right wear profile improves crusher performance and extends wear life, leading to less downtime and fewer liner replacements, which in turn increases safety and reduces the cost per ton. Our cone crusher wear parts are available for all Outotec crushing equipment, but we also offer crusher wears for non- Outotec crusher models.

Learn More

Crushing and Screening Handbook - AusIMM

Examples of calculation results using a cone crusher. Crushing zones, crushing force and esti- mation of wear profile after 10% of liner life used.

Learn More

cone crusher liner profiles | spare wearing ring of stone crusher

The wear model is derived based on Archard theory and is calibrated with the measured wear profiles of the liner from a PYGB1821 cone crusher. owatonna 95 mill main frame bushing hammer mill part manufacturers hp300 measuring tool thread wear gauge crusher cylinder pin bush bolt thread gauge

Learn More

How to Choose the Right Material for Cone Crusher Linings?

Choose the right liner for your cone crusher by defining the chamber profile. If you don't know the chamber

Learn More

cone crusher liner profiles | single toggle and double toggle jaw crusher

An inadequate liner profile can lead to increased downtime through excess liner wear, low efficiency and, in Prediction of Cone Crusher Performance Considering Liner. Cone crushers are used in the aggregates and mining industries to crush rock material. The pressure on cone crusher liners is the key factor that influences Cone crusher

Learn More

cone crusher liner profiles | casting parts for ball mill

Standard Head Liner Profiles CSS. Selecting crushing chambers for cone crusher. 7/4/ · There is a variety of things to take into consideration when selecting a cone crusher chamber profile to best suit your needs. An inadequate liner profile can lead to increased downtime through excess liner wear, low efficiency and, in Research on

Learn More