double roller crusher design line - Crusher production line of large

7月 16, · double roller crusher design, double roller crusher design Double Roller Crusher Shunzhi Advanced Technology Double Roller Crusher From ChinaDouble Roller Crusher Roller Crusher Price Zhengzhou Professional Coal Double Roller Crusher ShDouble Crusher Professional Quarry Stone Double Stage Hammer Crusher For SaleDouble Crusher High Efficiency Double Toggle Jaw

Learn More

Roll Crusher Manufacturer & Design

Roll Crushers are simple in design and construction, long-lasting, economical, and versatile across many applications and industries. A combination of impact,

Learn More

roller crusher in venezuela

2 Roller Crusher Double Rollers Crusher Double Roll Crusher. Jxsc mining roller double crushers are simple in design and construction, low maintenance cost,

Learn More

Source The Ideal Wholesale double roll crusher design - Alibaba

new design double toothed roll crusher,roller crusher for coal powder,roll breaker machine / Set 1 Set (Min. Order) 14 YRS CN Supplier Contact Supplier 1/6 China made small

Learn More

Lab Stone Double Roller Crusher Design For Construction Equipment For Crushing

5/25 · Double Roller Crusher - JXSC Machine. Double Roll Crushers Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feeds.:::(3)

Learn More

DOUBLE ROLL CRUSHER - Binder+Co AG

Furthermore, double roll crushers crush glass/cork connections (glass in screw connections or glass around corks), bottlenecks and thick bottle bottoms.

Learn More

Double Roll Crusher Design Principles

Double Roller Crusher Design Vakhusicoa Roll Crushing 911 Metallurgist. Feb 23 The crushing action of roll crushers on rock is completely by compression. Moreover the actions of the single and doubleroll forms of this type . for crushing hard rock or

Learn More

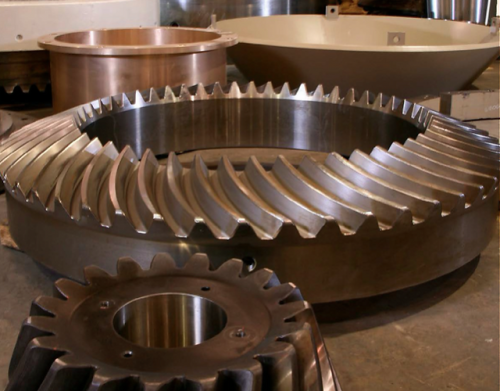

The tooth design and force analysis of the toothed roller

This paper presents a new type of crusher tooth that's double key location and easy to dismantle, and analyses the force of the crusher at all points during

Learn More

Double roller crusher

The sealing system of hammer crusher solves the problem of dust pollution and ash leakage. 4.The design of structure is tight, the wear-part is very seldom, and

Learn More

New Design Tooth Roller Crusher Double Roller Crusher

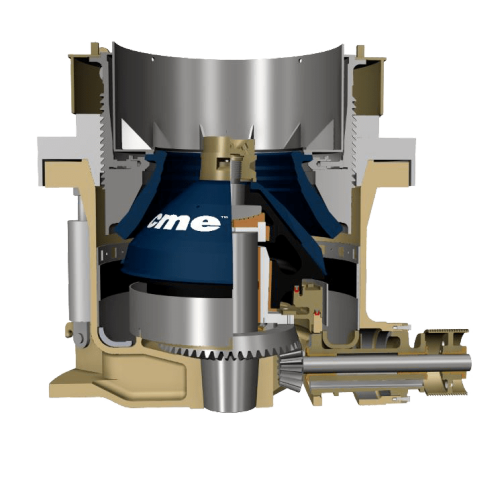

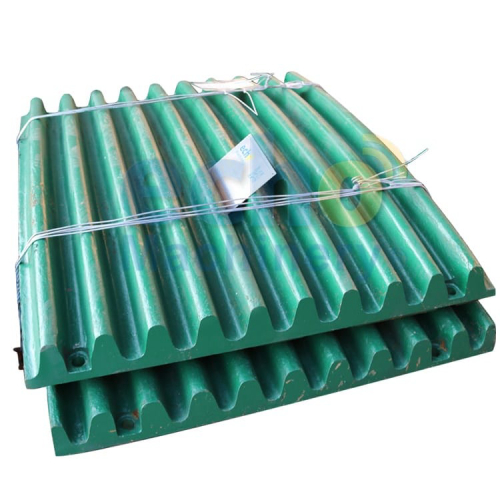

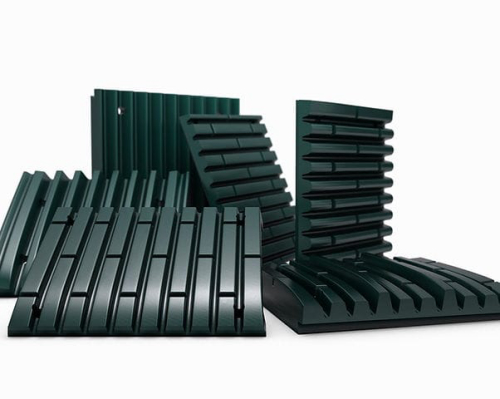

Double Roll Crushers. Double roll crushers reduce primarily through compression, although some shear is obtained with toothed rolls. Rolls for these crushers come in combinations of smooth, corrugated, and toothed designs. Double Roll Crushers produce a finer product at lower reduction ratios and capacities.:::As the main working part, the two cylindrical rollers rotate oppositely to Read more

Learn More

PDF) The Influence of the Structure of Double Toothed Roller

The best test scheme and the order of three influencing factors are obtained, which provides the basis for the design of the double toothed roller crusher.

Learn More

What is a Roll Crusher? (with pictures) - About Mechanics

The second set of rollers crushes the material once more to achieve a finer finished product. These machines feature a relatively simple design,

Learn More

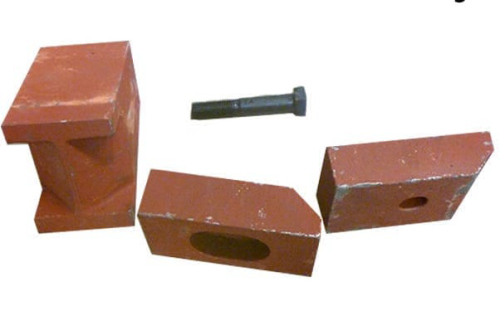

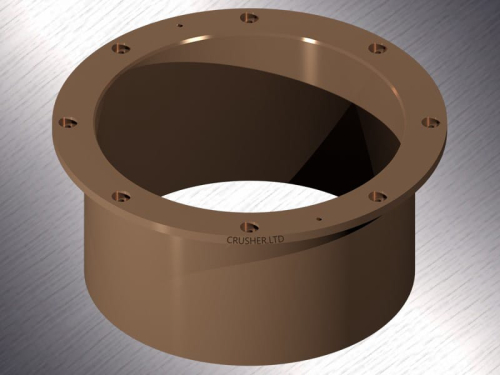

crusher spares | double roller crusher design

Dec 16, · Crusher Spares, Concave, Mantle, Jaw Platw, Cheek Plate, Wedge, Segment, Arm Shield, Crusher Spare Parts, Crusher Parts Company Introduction Deyang Realong Machinofacture Co., Ltd., as one of the leading professional foundries with over 30 years experience, specialized in producing and supplying high manganese steel wear parts.

Learn More

Double Roll Crusher | Henan Deya Machinery Co., Ltd

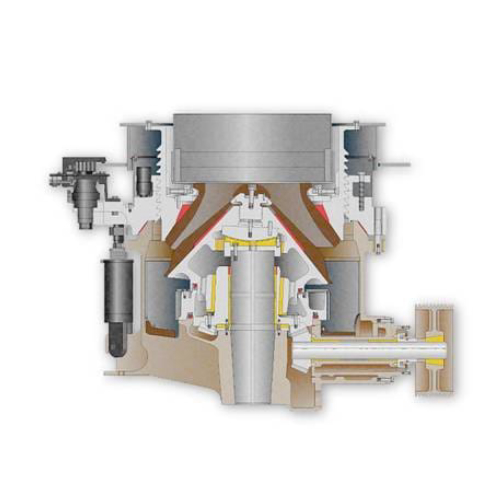

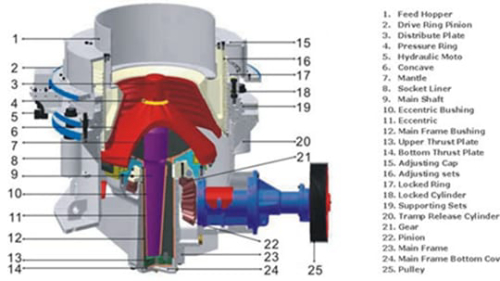

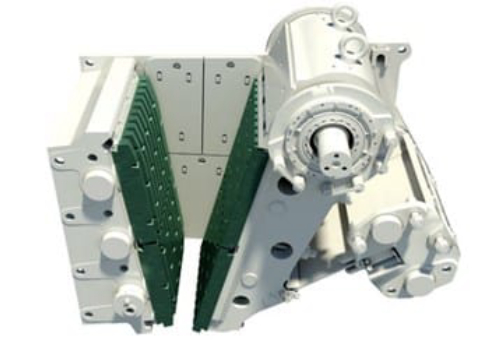

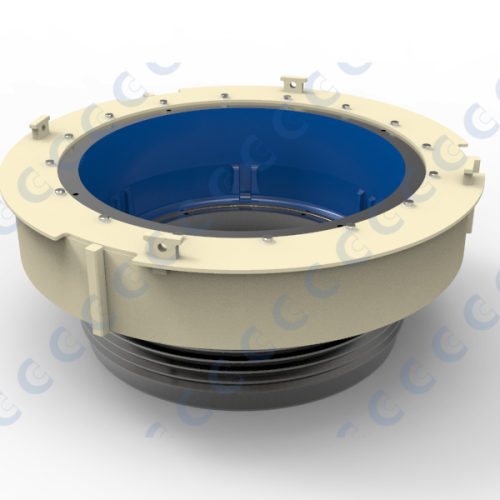

Double roll crusher (also called twin roll crusher) is composed of two cylindrical rollers as the main working mechanism (Figure 1). When working, the two round rollers rotate in opposite directions, and the material (ore) is crushed by the friction between the rollers, which rolls the material into the crushing cavity formed by the two rollers.

Learn More

Lab Stone Double Roller Crusher Design For Construction

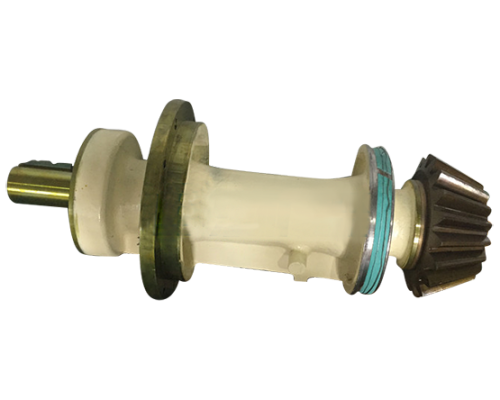

Roll Crusher is made up of two cylindrical rolls which are installed horizontally.The two rolls rotate in different directions, materials fall on top of the

Learn More

What's a Double-Roller Crusher? - Eastman Rock Crusher

The crushing particle size of the double stick crusher is between 1-20mm, and the specific discharge particle size can be realized by adjusting the gap between the two rollers. What are the characteristics of double-stick crushing and sand making? Roller design, can process both wet and dry materials.

Learn More

Double Roll Crusher Design - Gordon van Veelen

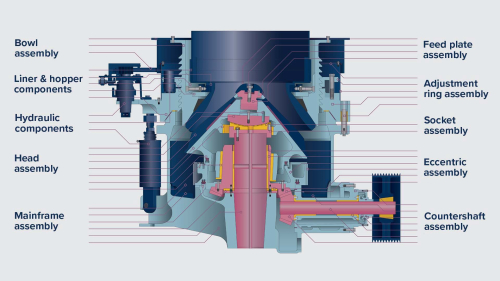

Apr 24, DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedge.The wedge

Learn More

Roll Crusher| Double Roller Crusher |DOVE

6/25 · Double Roller Crusher. DOVE Roll Crushers are designed with compact structure, small space installation, Light weight, Convenient operation, and low maintenance. DOVE Tooth Roll Crushers are

Learn More

double crusher roller teeth design calculations - GodSend

11/13 · Double Roll amp Teethed Roll Crusher. Feb 24, Feb 24, The single-roll crusher has a tip speed of 400-450 ft/min while the 6- x 7-ft teethed roll crusher has a normal, no-load, surfaces speed of just under 3500 ft/min. It can be readily appreciated that this high velocity induces an extremely violent crushing action, in conjunction

Learn More

Roll Crushers - Top 2022 Models - 911 Metallurgist

The standard spring roll crusher have two horizontally mounted cylinders. for crushing hard rock or ore. roll crusher design chart and crushing capacity.

Learn More

CPC Double Roll Crusher - SIEBTECHNIK TEMA

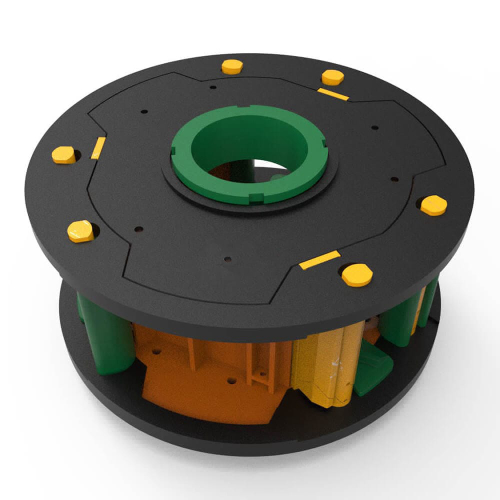

CPC Double Roll Crusher - Coarse size reduction of hard and medium-hard Design of crushing teeth according to the material requirements (number, size,

Learn More

The Influence of the Structure of Double Toothed ... - IOPscience

The best test scheme and the order of three influencing factors are obtained, which provides the basis for the design of the double toothed roller crusher.

Learn More

Double Roll Crusher, 13mm Particle Size - Gilson Co.

Price: $34,300.00 Description Specifications Questions? Double Roll Crushers are designed for single-pass size reduction of medium-hard to hard materials such as rock or ore to a nominal minus 10 mesh. Topsize is approximately 13mm and final fineness typically passes a No. 10 (2mm) opening, depending on material type.

Learn More

Double Roller Crusher-Baichy Machinery

Double roller crusher is mainly used for secondary and fine crushing materials with soft or middle hardness like coal, coke, limestone, clinker mineral, slag, shale and so on. Depending on the requirements, the rolls are smooth or toothed. ≤100mm Feed Size. 11-90KW Motor Power. 10-85 t/h Processing capacity.

Learn More

Double-roller Crusher - Shuliy Machinery

The double-roller crusher is mainly used for crushing ore. This machine has the advantages of small size, good crushing effect, low noise, simple structure, convenient maintenance, uniform size of crushed materials, sensitive overload protection, safety and reliability. It is suitable for coal, metallurgy, mining, chemical, building materials

Learn More

Roll Crusher | HRC - HAZEMAG

HAZEMAG Roll Crusher.For the crushing of lower to medium hard rock;reduced fines in the end product and high ability to deal with wet, sticky material.

Learn More