high quality - helical-bevel-gear

Hypoid Bevel Vs Straight Spiral Bevel - What's the Big difference? Spiral gears arrive in a lot of diverse types, but there is a fundamental variation between a Hypoid bevel gear and a Straight spiral bevel. This article will explain the variations in

Learn More

OEM - helical-bevel-gear

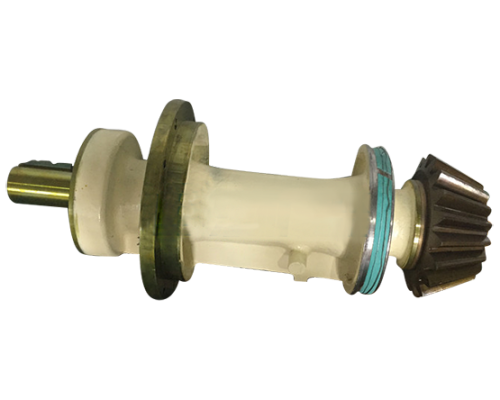

The Hypoid bevel equipment is comparable to the spiral bevel equipment but differs in the condition of the enamel and pinion. The smallest ratio would outcome in the cheapest gear reduction. A Hypoid bevel equipment is quite resilient and productive. It can be utilized in confined areas and weighs much less than an equal cylindrical equipment.

Learn More

Spiral Bevel and Hypoid Gear Cutting Technology Update

introduced. Today, gears are made on high-production, automated machines with direct drives and precision cutting tools. Face Mill (Single Index) and Face Hob (Continuous Index). There

Learn More

EXPECT INCREASED EFFICIENCY WITH HYPOID GEARING

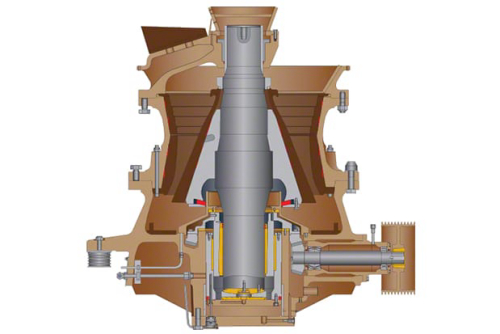

There are several types of right-angle gearboxes, including straight bevel, spiral bevel, hypoid and worm. The primary differences among

Learn More

Hypoid VS Spiral Bevel Gear Systems

From a physical standpoint, there is just one main difference between the two different types of gears: In a spiral bevel gearset, the pinion center line

Learn More

High on Hypoids | Electronic Design

In addition, hypoid gears tend to run smoother and quieter than spiral bevel gears. According to Dudley's, efficiency of a hypoid gear (90

Learn More

hypoid Vs spiral bevel | Pirate 4x4

May 12, · Hypoid spiral bevel gears are always stronger than standard spiral bevel gears. This is due to the fact that regardless of whether it is running on the drive or coast side, there is

Learn More

Analysis of the advantages and disadvantages of hypoid gear and spiral

When the transmission ratio is less than 2, the hyperboloid driving gear is too large compared with the spiral bevel gear, occupying too much space. At this time, the spiral bevel gear transmission can be selected, because the spiral bevel gear transmission has a large differential available space. For medium ratios, both gear drives are available.

Learn More

China Hypoid Gear Spiral Bevel Gear Factory and Manufacturers

We're hunting forward to your check out for joint development for Hypoid Gear Spiral Bevel Gear, Hypoid Vs Worm Drive, Hypoid Spiral Gear, Stainless Steel Spur Gears,Purchase Spur Gears. Inspired by the rapid developing market of the fast food and beverage consumables all over the world , We are looking forward to working with partners/clients

Learn More

hypoid Vs spiral bevel | Page 2 | Pirate 4x4

May 13, · hypoid Vs spiral bevel. Jump to Latest Follow 21 - 29 of 29 Posts. Prev. 1; 2; 2 of 2 Go to page. Go. S

Learn More

Hypoid gear and spiral bevel gear|Gear|Product information|Nippon Gear

The official website of Nippon Gear Co., Ltd. The hypoid gears and spiral bevel gears, which are gears offered by Nippon Gear Co., Ltd., are introduced.

Learn More

PDF Spiral Bevel and Hypoid Gear Cutting Technology UpdatePDF

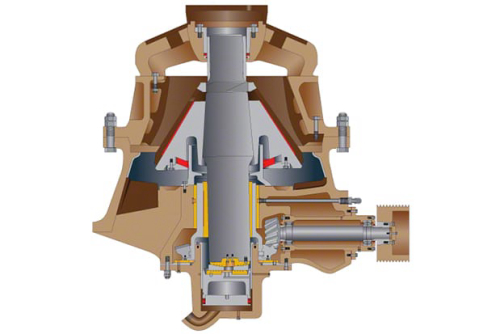

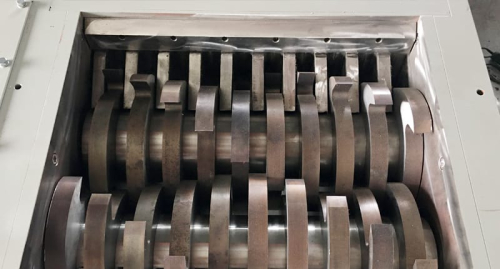

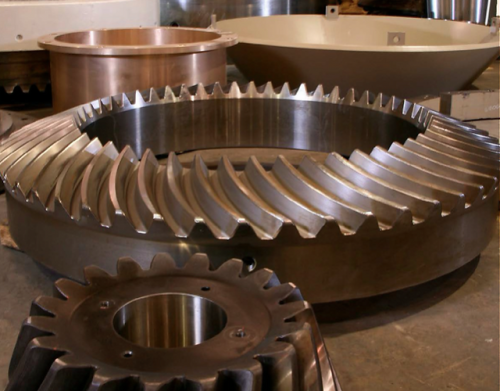

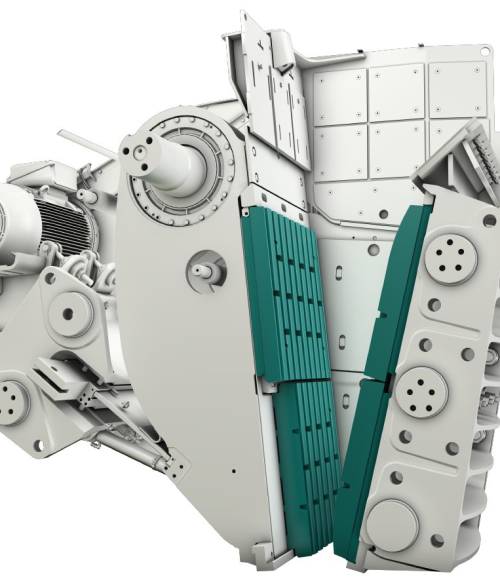

There are two main meth- ods of producing spiral bevel and hypoid gears in the production environment today. There is the single indexing method referred to as face milling (Fig. 1), and the continuous indexing method (Fig. 2) referred to as face hobbing.

Learn More

Hypoid Gears - A Long Way from Truck Axles to Motion Control

However, hypoid gears are usually less efficient (90 to 95%) than a similar set of spiral bevel gears, which can have efficiency ratings up to 99%. The efficiency of hypoid gears decreases as the axis offset increases and special attention must be given to lubrication to prevent gear wear as a result of the sliding action of hypoid gear teeth.

Learn More

What's the Difference Between Spur, Helical, Bevel, and Worm

Hypoid gears are a type of spiral gear in which the shape is a revolved hyperboloid instead of conical shape. The hypoid gear places the pinion

Learn More

supplier - spiral-gear

The benefits of a hypoid equipment above a spiral bevel gear incorporate a greater get in touch with ratio and a higher transmission torque. These gears are mainly utilised in vehicle push techniques, the place the ratio of a single pair of hypoid gears is the optimum. The hypoid gear can be warmth-taken care of to boost toughness and reduce

Learn More

Hypoid bevel gear VS spiral bevel gear

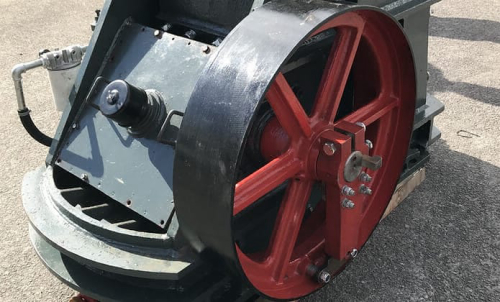

Spiral bevel gears and hypoid bevel gears are the main transmission methods used in automobile final reducers.

Learn More

Expect Increased Efficiency With Hypoid Gearing Instead

The shape of a hypoid gear is hyperbolic; the shape of a spiral bevel gear is normally conical. A hypoid gear has a 25:1 ratio range. A hypoid gear set, in this ratio range, is approximately 90%

Learn More

Spiral Bevel Gear-Kawasaki City's ground spiral bevel gear manufacturer

Spiral bevel gear. A well-known leading manufacturer in Kawasaki City, we provide ground spiral bevel gears, locomotive spiral bevel gears, Grootvlei spiral bevel gears, hyperboloid bevel gears and Zerol bevel gears. Grinding spiral bevel gears.

Learn More

Comparison of hypoid, helical bevel and worm gear motors

Our experience shows that the average efficiency of a hypoid gear unit is 88% with two stages and 83% with three stages. The efficiency of a helical bevel gear

Learn More

Spiral Gears and Hypoid Gears - Agro Engineers

Conventional straight-cut or spur-cut gears, with perpendicular teeth, are considered to be too noisy in use, and a normal spiral bevel does not always give sufficient contact area. The hypoid gear places the pinion off-axis to the crown wheel which allows the pinion to be larger in diameter.

Learn More

Hypoid Gears – A Long Way from Truck Axles to Motion Control

Hypoid gears offer more ratios, higher torque capacities, higher running speeds, and less noise than their bevel counterparts. However, hypoid

Learn More

Less Energy Consumption with High-Efficiency Bevel gears

spiral bevel and hypoid gears in single-reduction axles. Introduction. The efficiency of a gearbox is the out- put energy divided by the input energy.

Learn More

PDF Tribology Aspects in Angular Transmission Systems - Gear TechnologyPDF

Axes cross under any angle → hypoid gears (line contact) Zerol bevel gears are the special case of spiral bevel gears with a spiral angle of 0°. They are manufactured in a single-indexing face milling process with large cutter diam-eters, an extra deep tooth profile and tapered tooth depth. The axis of Zerol bevel gears

Learn More

Hypoid vs Spiral/Bevel/Spur gears and their lubrication

The advantage of hypoid gears is twofold: They're stronger than right angle bevel gears, and quieter. I think there is a small amount of sliding in gears using an involute

Learn More

HYPOID GEAR OIL: WHAT IT IS AND WHEN TO USE IT - Kendall Motor Oil

Hypoid gearboxes are found in most of today's modern vehicles. They are commonly used in rear axle differentials, where they transmit power from the driveline to the axle shafts. They are a type of spiral bevel gear with a left-hand spiral angle on the pinion and a right-hand spiral angle on the crown. This lowers the driveshaft away from the

Learn More

Spiral Bevel Gears and Hypoid Gears | SpringerLink

The load analysis of spiral bevel gears is then performed, also defining the thrust characteristic on shafts and bearings. Subsequently, the

Learn More