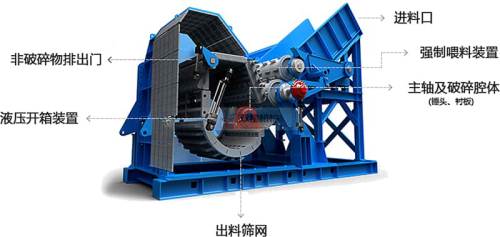

Roll crusher working principle & structure

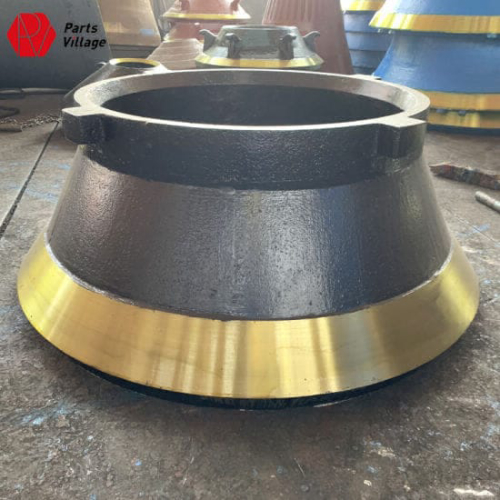

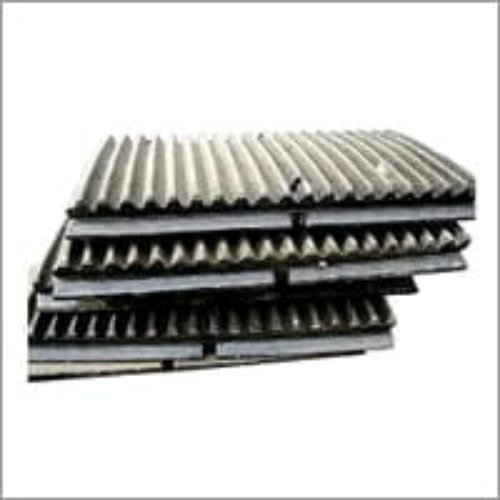

The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on

Learn More

Working Principle Of Smooth Roll Crushers - Stone Crushing Machine

Structure and WorkingPrincipleof RollCrusher: 1. This series of rollcrusheris composed by several parts of rollwheel, rollwheel axial bearing, Click & Chat Now Related Solutions Best Blower For Raymond Mill For Sale 1500 Tph Limestone Impact Crusher Iron Metal Separator Supplier By Using Belt Conveyor Pulleys

Learn More

Single Roll Crusher Principle Pdf - HN droled mine treatment

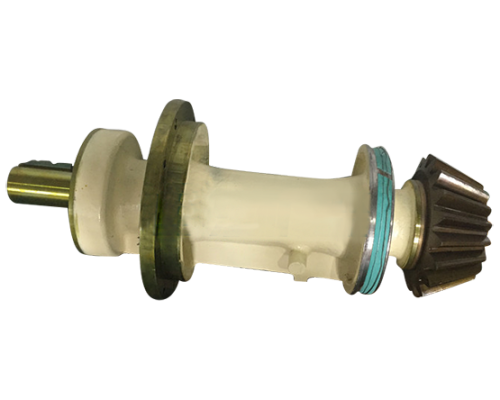

Roll Crushers Slideshare. apr 24, double roll crusher working principle and structure of double roller crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedge.the wedge .

Learn More

single roller crusher working principle - ataFinch

Doubleroller crusher working principle. The mode of operation of rollcrushersis extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other. The set is determined by shims which cause the spring-loaded roll to be held back from the solidly mounted roll

Learn More

roller crusher working principle stone crusher machine

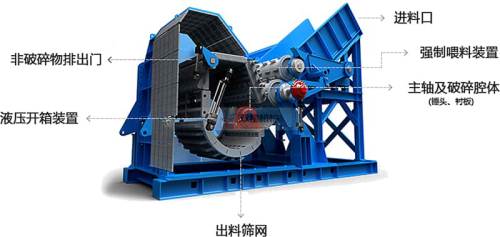

Working Principle Single stage crusher is composed with rotor bearing discharge grate bearing plant main body and the drive section The hammer head will

Learn More

Single Roll Crusher Working Principle Definition In Reunion

Single Roll Crusher Working Principle Definition In Reunion / the working principle of jaw crushers all jaw crushers feature two jaws one of which is fixed while the other moves. the working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the

Learn More

Roll Crusher With stable Performance | Fote Machinery

Roll crusher working principle, The spring is used to balance the pressure generated between the rolls. If there are non-crushed materials falling between the two rollers, the compression spring of bearings can be pushed to make a large gap so that non

Learn More

single roller crusher working principle

single roller crusher working principle. May 31, Single Roll Crushers. The Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines. The minimum product sizing of a Single Roll Crusher is generally limited to 2-3".

Learn More

Single Roll Crusher-Products-Ande metallurgical

Single-roll crusher is applied for crushing of fragile and low/medium-hardness material, such as sinter, slag, shale, limestone and etc.

Learn More

Double Toothed Roll Crusher - Fote Machinery

The two-toothed rollers adopt non-meshing and non-constant speed operation to strengthen the degree of occlusion, which ideally prevents the material from

Learn More

discussion on roll crusher

roll crusher works utilizing a rotary roll. the rpm speed is somewhat lower than the impact crusher, which is 300 rpm. with more production power, the work of

Learn More

Structure and Working Principle of Single Roll Crusher

When the single roll crusher works, under the friction force of the rollers and the materials, the materials fed between the two rollers will stick on the rollers with the rotation of the rollers and

Learn More

Single-roll crushers | dhmgroup

Single-roll crushers crush the sinter received directly from sintering machines. Crushers consist of a body, a pull-out grate, a runner, a tilted plate and a drive with a planetary reduction gear. The inner surface of the body is covered with moving plates. Special features:

Learn More

Roll Crushers - Top 2022 Models - 911Metallurgist

The standard spring roll crusher have two horizontally mounted cylinders. The set is determined by spacing pieces (shims) which cause the spring-loaded roll to be held back on its sliding mounting from the solidly mounted roll. Modern rolls have both cylinders positively driven by separate motors, so that they rotate inward and downward.

Learn More

highway double roller crusher machine

Double roll crusher double roll crushers are the most common type of roll crushers the crusher machine uses two opposite rotating rollers to crush the material

Learn More

Single Roll Crusher Working Principle Manufacture and Single Roll

Single Roll Crusher Working Principle - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Wire Rod Plant Rolling Mill Machine.

Learn More

Roll Crusher Working Principle

Single Roll Crushers Mineral Processing Metallurgy. Metallurgical ContentRoll Crushing Action and Working PrincipleDischarge Product of a Roll CrusherOptimal Roll Crusher Feed SizeRoll Crusher CapacityApplications: When to use a Roll Crusher On the right, a Roll Crushers is shown in a sectional elevation o . View Details Send Enquiry Working Principle Of Smooth

Learn More

Single Roll Crushers - TerraSource Global

plate and the roll itself. The roll then pinches the material against the stationary breaker plate, and simultaneously, the material is crushed by the shearing action of the roll teeth and

Learn More

Roll Crushers - SolidsWiki

The probable reason is because the large mines require very large crushed product output with minimal cost, makes the roll crusher uncompetitive

Learn More

Working Principle of Crushers - Mineral Processing & Metallurgy

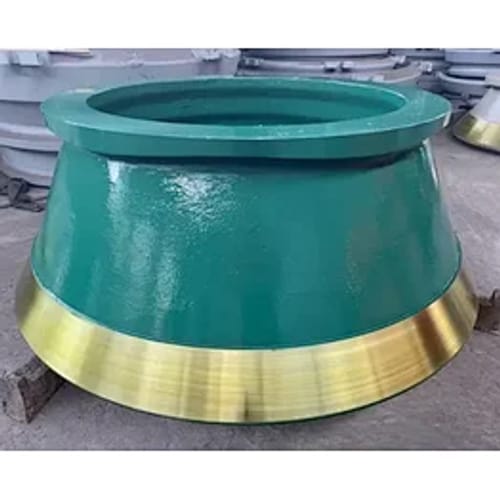

Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position "1." Note that the length of line "1″ from concave to open-side head position, is the same as that of line "O" from concave to close-side head position.

Learn More

Roll crushers - SlideShare

ROLL CRUSHER Roll crushers are used for producing additional reductions in the sizes of stone. The particles are drawn into the gap between the rolls by

Learn More

Mechanical structure of roller crusher. - ResearchGate

Roller crusher is widely used in solid and block material pulverizing. Roll gap between the rollers is usually adjusted to satisfy the particle size of

Learn More

single roll crusher working principle 2

SINGLE ROLL CRUSHERS DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller roller support bearing compression and adjusting device drive components etc. 2.the adjustment of the particle size between the two rollers equipped with adjustment device like pads

Learn More

Single Roll Crusher Working Principle In Lesotho

A required crushing process may consist of just one rotor crusher a combination of two rotor crushers a combination of one rotor and one roll crusher or just one roll crusher rotor crushers can treat quite coarse material with maximum inlet size of some 300 300 mm as the typical crushing ratio is 10 at a single stage the material can be.

Learn More

Working Of Single Roll Crusher

The working principle of toothed roll crusher: Single-toothed crusher is composed of one rotating toothed roller and one curved crushing plate. The tooth on the roller surface can bite the coal and crush, in this way, the crushed material will discharge from the bottom with the rotation of roller.

Learn More

Single Roll Crusher Principle Pdf - HN droled mine treatment equipment

Roll Crushers Slideshare. apr 24, double roll crusher working principle and structure of double roller crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two rollers equipped with adjustment

Learn More