China Bowl Liner For Cone Crusher Factory and Suppliers

Bowl Liner For Cone Crusher - China Factory, Suppliers, Manufacturers · CJ08700-340-22U.180 · Liner Upr · ADAPTER RING.2 · Adapter Ring · 6003942 ROTOR TIPS.402

Learn More

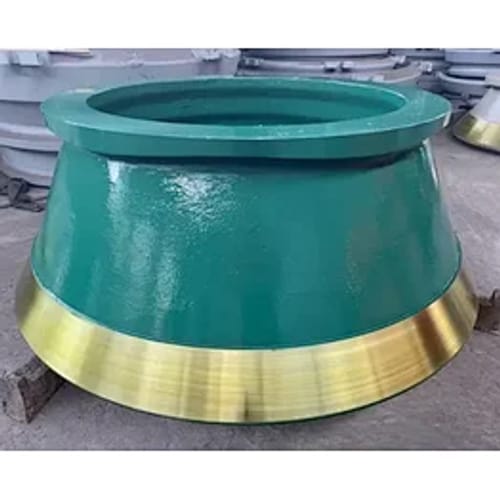

Bowl Liner & Mantle | Wear Resistant Crusher Parts - GTEK

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper

Learn More

Parts "48′ gyradisc low liner | cone crusher gap setting

cone crusher 2 Lockpost Seal For Cone Crusher. Spaulding Crusher Parts, Rock Crusher Parts for , Gryradisc, and HP Crushers.SEC Parts is a leading manufacturer of aftermarket crusher parts for HP Crushers, Cone Crushers, and Gyradisc Crushers. Our high quality crusher parts are made for the HP Crusher 300 and 400 series

Learn More

How to Find the Right Cone Crusher Liners Manufacturer?

There are three basic types of liners for cone crushers. A standard size has a standard diameter. The "A" dimension is the width of the cone liner. It is a standard measurement for all cone liners. A larger or smaller "A" dimension increases the life of the liner and increases the capacity of the machine.

Learn More

Manganese Cone Liners - Crusher Spares

We have an extensive range of standard and heavy duty design manganese liners to suit fixed plant and mobile cone crushers. Pegson900,

Learn More

Bowl Liner & Mantle | Wear Resistant Crusher Parts | GTEK

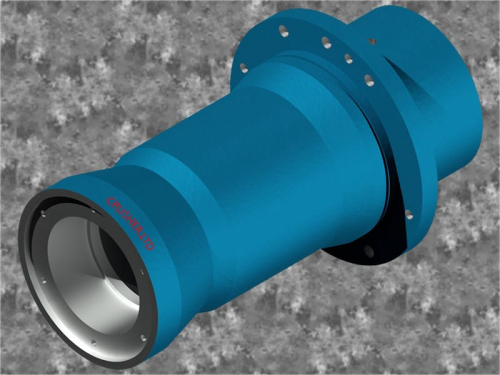

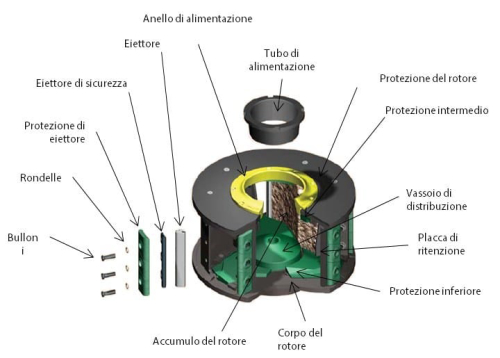

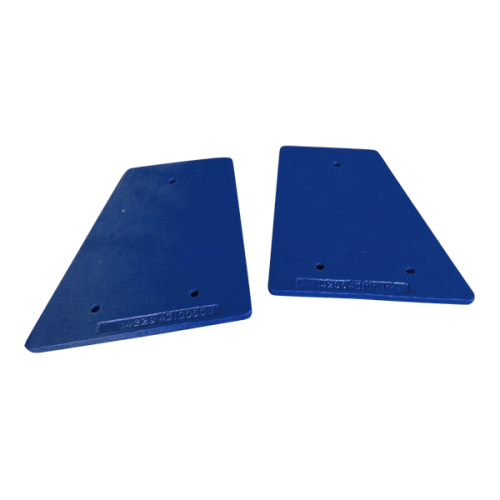

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl liner. The mantle covers the cone head to protect it from wear, we can see it as a sacrificial wear liner that sits on the cone head.

Learn More

Replacing the liner of a HP cone crusher - Outotec

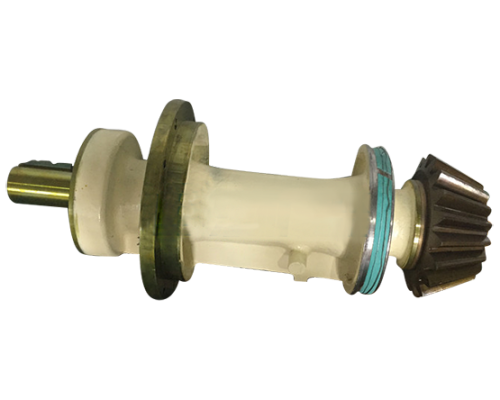

6/9 · A) Mantle - also known as head liner. B) Cutting ring - the cutting ring is not reusable, so a new ring should be installed every time the mantle is replaced. D) Padding material - its purpose is to cushion (shock absorption), not to fasten the liners. Lubrication of the head/bowl is recommended to facilitate subsequent replacement.

Learn More

cone crusher liner selection - Wear Parts For Industry - Qiming Casting

The manganese trademark : Mn13CrMo, Mn18Cr2Mo, Mn13Cr2Mo. Cone crusher liner selection chemical elements from Qiming Casting Test Report. From the test report, Mn13 is the high manganese steel and Mn18 is Ultra-high manganese steel, The content of elements "Si" can effect the Impact toughness , need less than 0.5%,the lower content of

Learn More

Prolonging Cone Crusher Liners Working Life - Precision Casting

The chamber is lined with wear components, cone crusher wear parts namely the mantle and concaves. As the stone drops though the choked chamber, squashing is attained when the motion of the mantle causes compressive and abrasive pressures to act upon the stone and also dish liner, creating the rock to damage.

Learn More

Cone Crusher Liners For Popular Brands With Various Material

Cone crusher liners mainly wear parts in the cone crusher, which are included cone crusher mantle and cone crusher concave. Cone crusher mantle, which covers the cone head of the

Learn More

Cone Crusher Solutions - Bradken

Bradken's cone crusher liner product range is designed to provide the safest solutions for product installation and materials handling, optimal performance

Learn More

Change Cone Crusher Liners - MGS Casting

1. On the initial set of new linings, put a mark on the change cap chauffeur ring where the pinion tooth reaches a chauffeur ring tooth when the target crusher setting has actually been achieved. 2. Keep an exact record of the variety of teeth made use of

Learn More

How To Select Cone Crusher Liners and When To Change Them

The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing the closed-side feed opening 40 to 60 percent going through the midpoint 0 to 10 percent leaving the closed-side setting Match the entire feed gradation and not only the feed shape.

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

Cone Crushers & Spares

Some of the Cone Crusher spares range that we stock include: Bowl liners and bolts Mantles Main shaft nuts Main shaft sleeves Mainframe liners Feed plates Inner eccentric bushes Outer eccentric bushes Bearings and socket liners Countershaft bushes Piston rings and dust seals Gears and pinions Head and shaft assemblies

Learn More

Cone Crusher Liners For Popular Brands With Various

Common Aliases: Cone crusher liners, Cone crusher wear parts, Manganese cone liners, Mantle and concave · Main Material: Mn14, Mn18, Mn22, Manganese alloy steel,

Learn More

China Mining Machinery Cone Crusher Parts High Mn Casting Cone Crusher Liners - China Cone Crusher Parts, Cone Crusher Liners

details about China Cone Crusher Parts, Cone Crusher Liners from Mining Machinery Cone Crusher Parts High Mn Casting Cone Crusher Liners - HENAN CRUSHTECHS MACHINERY CO., LTD. Sign In Join Free For Buyer Search Products & Suppliers

Learn More

crusher parts loaded on truck, cone liner, bowl liner ready for

crushtechs specialized in all kinds of crusher and crusher parts.cone liners, jaw liners, cone mantle liner, concave liner, jaw plate, impact crusher parts,

Learn More

HP100 BOWL LINER C

HP100 BOWL LINER C gyratory crusher mantle repair gravel crusher inner bushing spares gyratory crusher working principle pdf Quality, Versatility, Reliability for Thousands Less Impact Crushers lippmann 2021-03-22T16:59:40-05:00

Learn More

Crusher Liners | World-Leading Crusher Liners | CMS Cepcor

Cavity and liner selection. CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various metallurgies for impact crushers. Quality assured to Lloyds Register ISO9001:

Learn More

Tools for the MOBICONE cone crusher | PM | Kleemann

The cone and bowl liner must both be of the same variant (Standard or Short Head) and must not be combined with one another. · The bowl liners of both versions –

Learn More

Cone Crusher Liners Selection - Wear Parts For Industry - Qiming Casting

Cone crusher liners , the mainly wear parts in cone crusher, and also need exchange them very regularly.In this post, we will analysis the selection by cone crusher cavity,crusher liner's material and exchange time. We will choose cone crusher toanalysis. 1.Cone Crusher Cavity

Learn More

A Guide to Selecting Cone Crusher Liners - Optimum Crush

The liners of the cone crusher are crucial for protecting the mantle and the concaves inside the compression chamber from wear and tear. These are easily replaceable parts and have to be switched out often to maintain optimal performance. The Feed The biggest factor to consider when getting a new cone crusher liner is the feed.

Learn More

Manganese Steel Rib and Arm Liners for Cone Crusher

Satya Alloy Castings - Offering Manganese Steel Rib and Arm Liners for Cone Crusher, Thickness: 8 - 10 mm at Rs 900/piece in Hyderabad, Telangana.

Learn More

Cone Crusher - an overview | ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone angles of the breaking head. The approximate distance of the annular space at the discharge end designates the size of the cone crushers.

Learn More

What affects liner life? — SRP - rockprocessing

Extending the life of liners in your cone crushers can significantly reduce maintenance costs and improve productivity, so its vital that any problems in

Learn More